Dr. Andrew Mathers (X-ray CT Project Manager) scanned an American Football helmet to showcase the key components that help aid player safety in the modern game.

X-ray CT enables us to non-destructively visualise the different components of the fully assembled helmet and inspect them to assess their build quality and conformity with design, each of which plays a vital role in protecting the athlete.

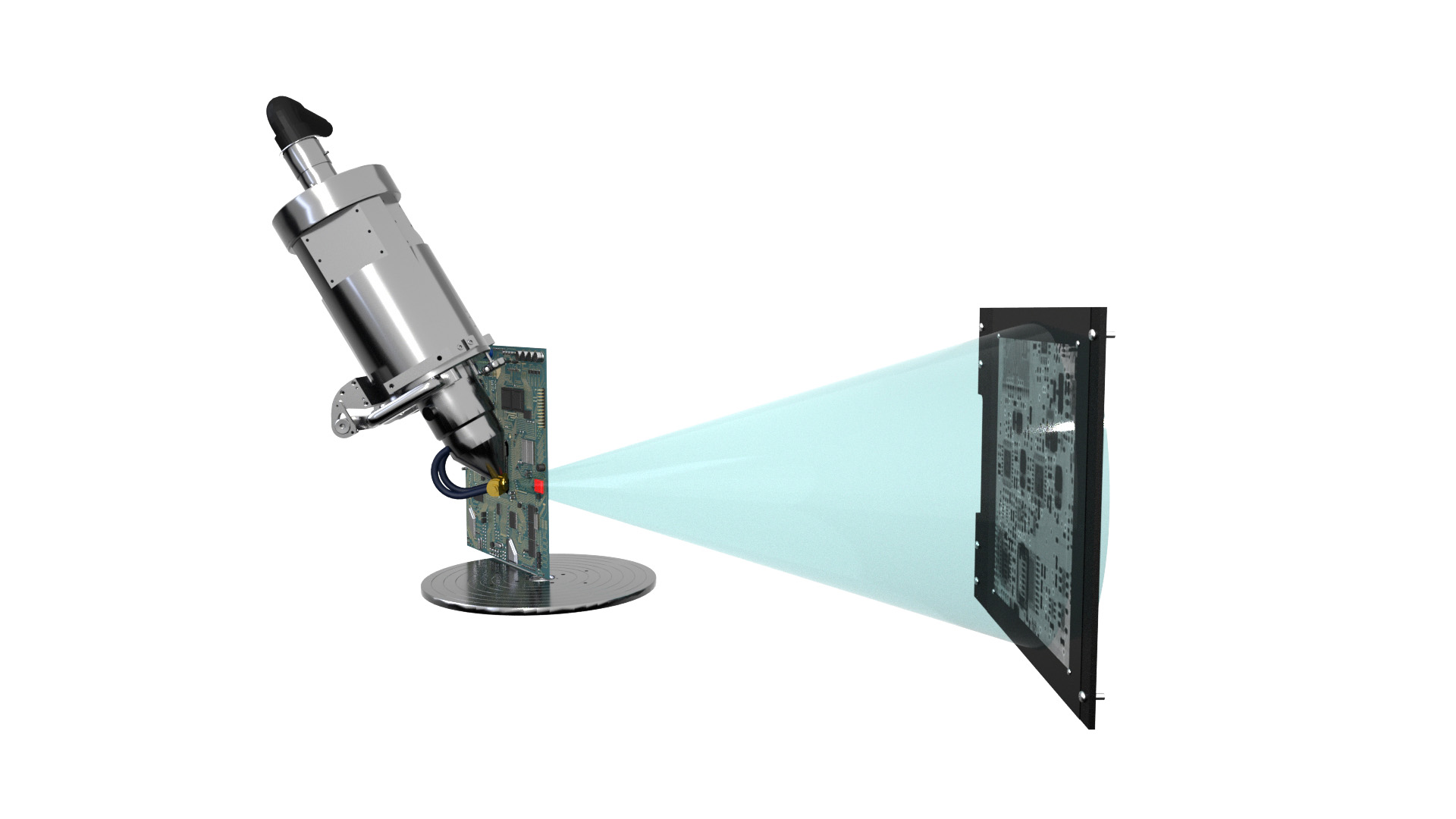

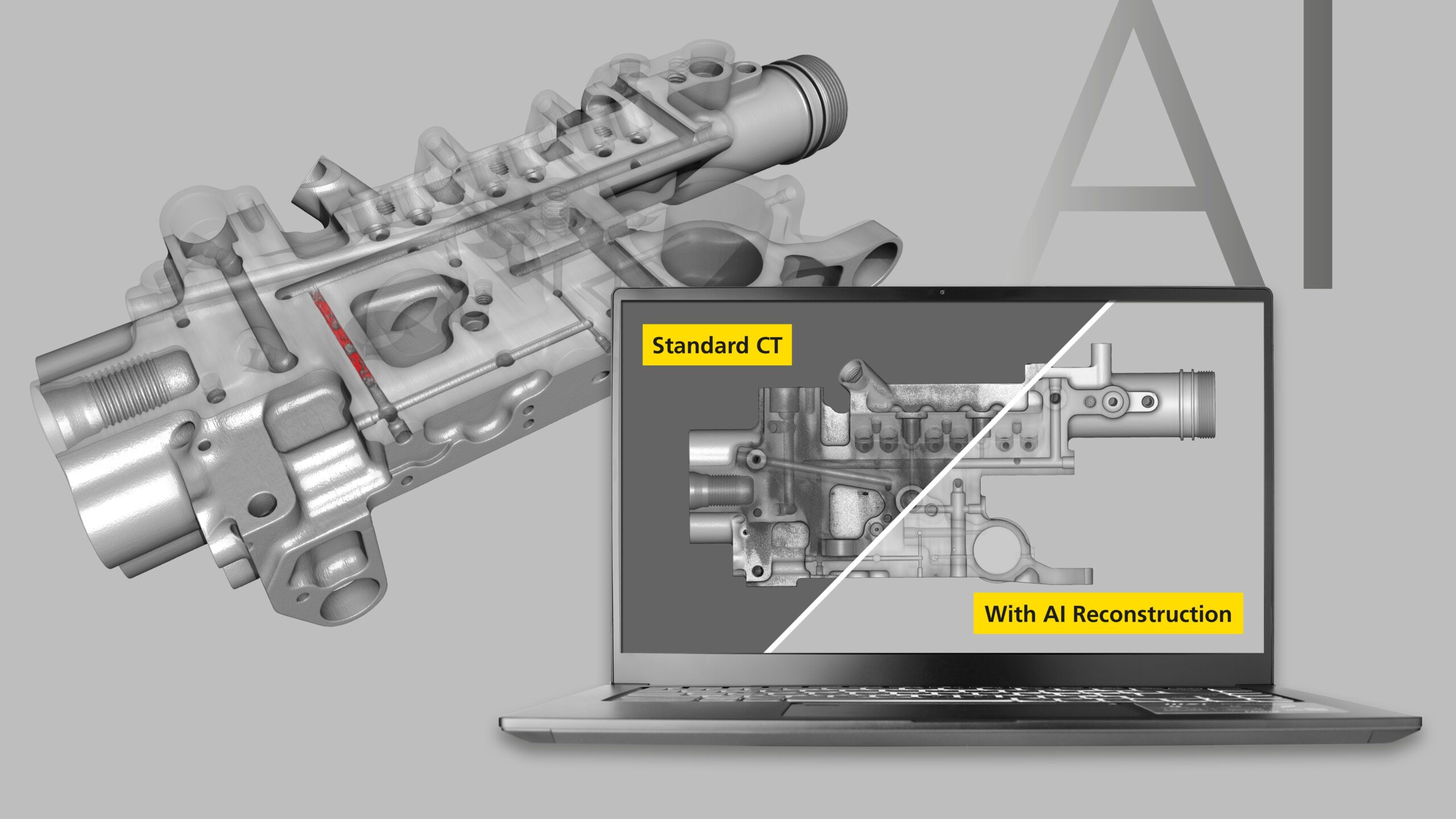

X-ray CT scans of the facemask and helmet were acquired at 143 and 156 µm voxel resolution and 450 and 350 Watts respectively, using a Nikon C2 Large Envelope System (LES). The system houses three X-ray sources (a Nikon 450kV microfocus with rotating target, a Varian 450kV minifocus and a Nikon 225kV microfocus with interchangeable rotating and reflection targets) and two detectors (a Varex 1621 EHS flat panel and a Nikon curved linear diode array). In this instance the Nikon 450kV rotating target and 225kV rotating target microfocus sources were used to acquire scans of the facemask and helmet, respectively. Both scans were performed using a Varex 1621 EHS flat panel detector, which acquired 3141 projections.

There has been much discussion over the last decade about the level of player safety, in particular the incidence and frequency of players suffering concussions, and the potential adverse effects this can have on a players’ health in later life. In response to this increased awareness team coaches, medical staff, league officials, sports safety educators and helmet manufacturers have all played their part in trying to improve player safety. This has resulted in league rule changes, the introduction of different tackling techniques, better education for coaches and players at all levels (and ages) of the game, greater penalties for dangerous play, revised medical protocols for concussion evaluation and return to play eligibility following concussion, and of course helmet design.

Unlike many other sports helmets, American Football helmets are designed to last years of punishment and provide protection for the athlete against thousands of impacts, rather than protection against a large single impact event (motor racing, cycling and horse riding), which typically renders the helmet unusable or necessitates immediate refurbishment. Like all sports helmets the quality of the fit is essential not just to the athlete’s performance, but also its own performance.

A typical modern-day American Football helmet (like the one we scanned) consists of the following components, all of which come in a range of shapes and sizes to maximise comfort, fit and playing performance:

- a lightweight polycarbonate outer shell which helps deflect or delocalise the force of impact

- a metal facemask, typically constructed of stainless steel, titanium, or carbon steel, wrapped in a Polyarmor 17 thermoplastic coating, which is impact and corrosion resistant

- an adjustable chin strap system with either a hard polycarbonate or soft cloth cup (depending on the athlete’s preference), which is fastened at multiple mounting points on the outer shell to help secure the helmet firmly in place:

- a pair of cheek pads and a forehead pad array, these components are typically filled with impact absorbing foam or a series of air pockets to help absorb and dissipate high velocity impacts

- shock absorbing structural elements for the top, back and sides of the cranium, including foam padding and a thermoplastic matrix and interconnected systems of inflatable bladders to ensure a high-quality fit for any head shape

Other helmet components designed for safety in the modern game include:

- impact loggers and sensors which provide real time or recoverable data to monitor an athlete’s exposure to impacts, including the direction, location and force exerted

- visors which attach to the facemask to prevent eye injuries from physical contact, protect eye health by reducing dirt ingress from the playing surface and improve visibility by reducing glare; in some cases tinted or coloured visors are worn to help assist players with chronic eye conditions.

X-ray CT data was reconstructed in Nikon CT Pro 3D and the resultant data was segmented and rendered in 3D in Volume Graphics Studio Max 3.4.