Products and promotions may differ based on your selected region.

AI Reconstruction: lifting the limits with Deep Learning

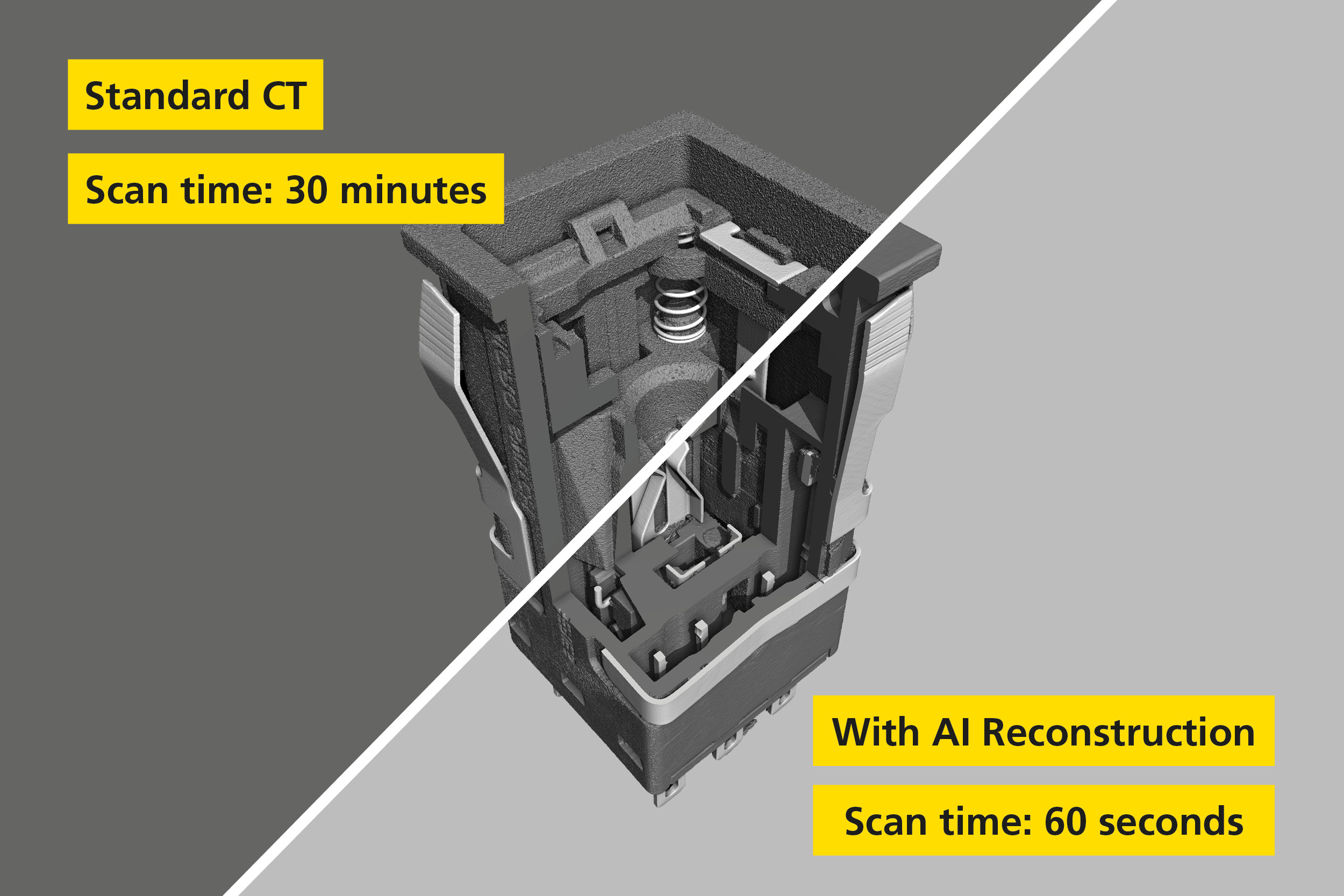

New level of Speed

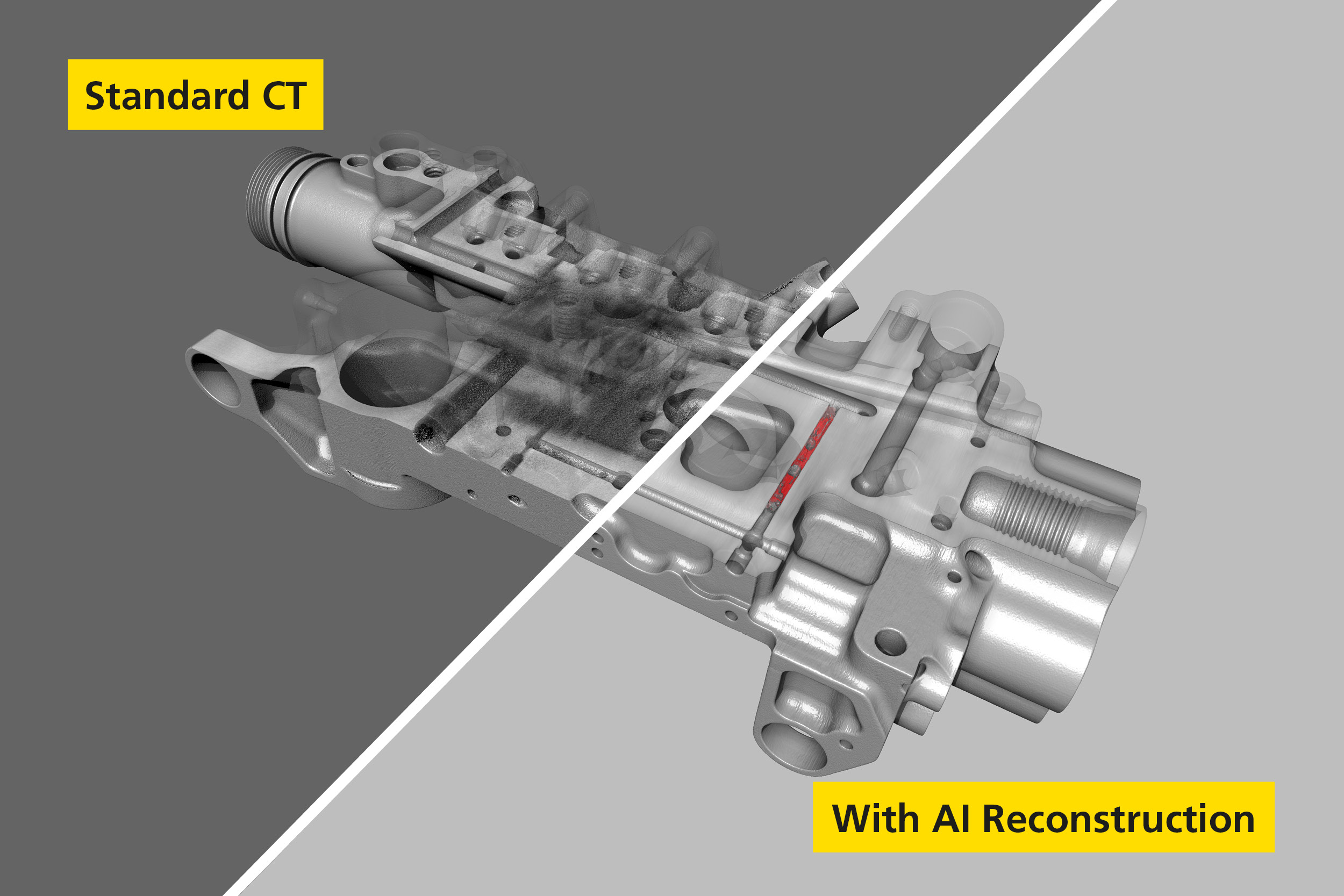

Nikon’s breakthrough AI Reconstruction leverages Deep Learning to change the industrial CT experience forever. Trained to distinguish relevant information from scan artifacts, users benefit from automated enhancement tailored to their specific needs, allowing users to discover minute flaws which may have previously been invisible to standard CT, while simultaneously boosting the speed of routine inspection.

AI Reconstruction is ideal for laboratory and production environments demanding pinpoint defect detection and high throughput. This includes those found in the automotive, aerospace and manufacturing sectors, and many more, as AI Reconstruction integrates seamlessly with leading analysis packages.

Product Highlights

Deep Learning AI

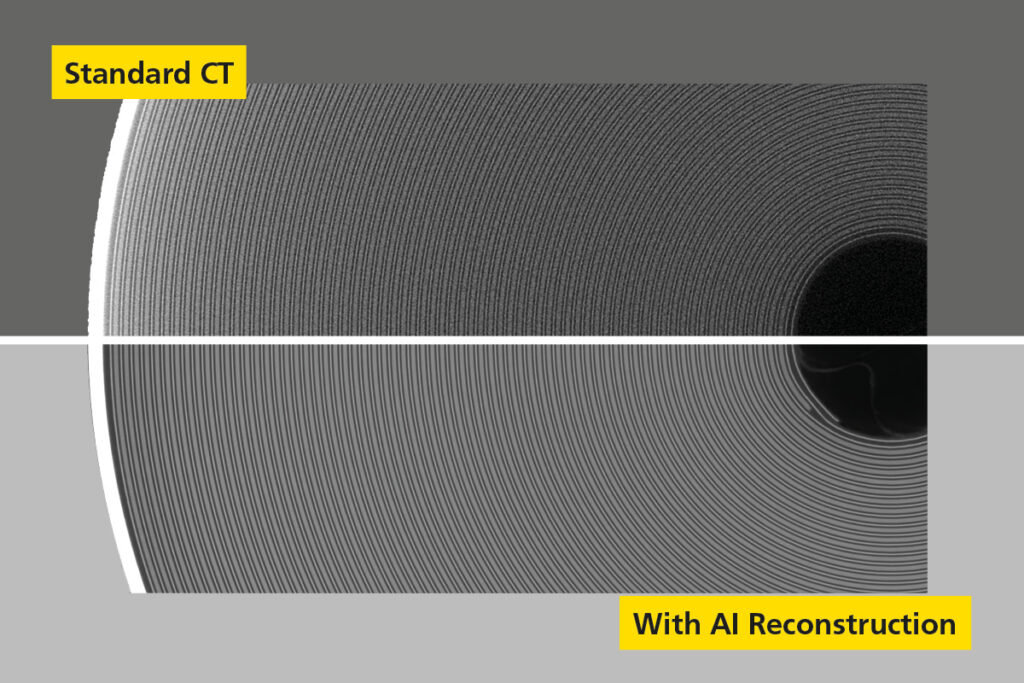

Nikon’s AI Reconstruction makes use of the immense potential of Deep Learning to lift the constraints that previously limited CT scanning. By training its models to distinguish relevant information from scan artifacts, AI Reconstruction filters noise and improves image clarity, providing superior scan quality and speed tailored to each customer’s needs.

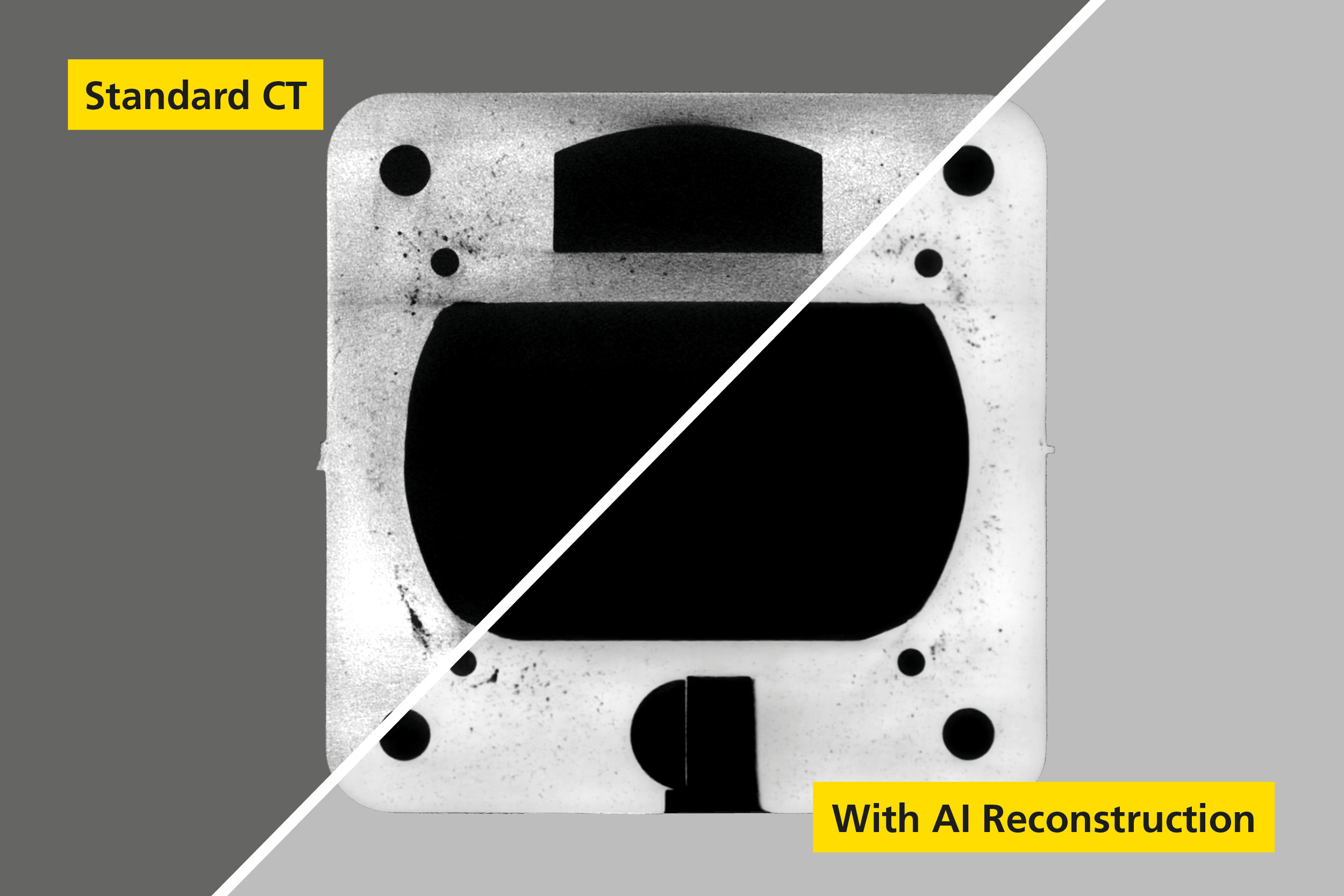

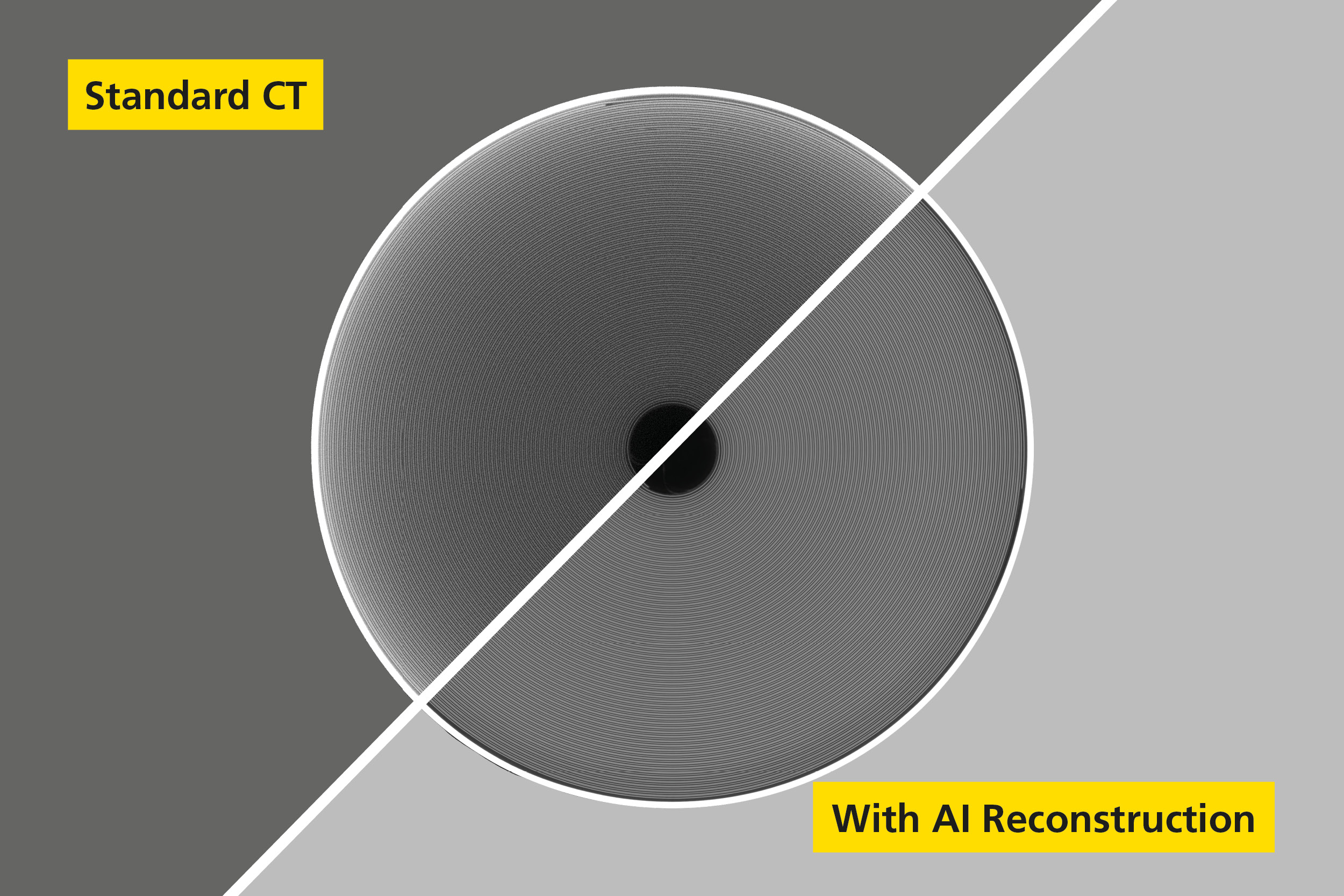

Better image quality

AI Reconstruction represents a fundamental advance in high-speed CT imaging. AI-powered enhancement techniques reveal minute product flaws that may be missed by traditional CT scans. Components can now be easily analysed to the highest standards, drastically improving inspection productivity while maintaining production speeds.

Faster scan speeds

AI Reconstruction delivers radically faster scan speeds, as well as providing enhanced image clarity, lifting the traditional limitations which have kept CT users from achieving rapid results. Customers can now conduct faster scans without compromising accuracy, inspecting more units per day while still catching fine defects.

Reliable and repeatable

AI Reconstruction delivers an adaptable automated solution for reliable mass production or regular batch testing workflows. The technology integrates with leading analysis platforms and AI models are fine-tuned to individual client needs by Nikon’s experienced Applications Engineering team.

Industry Applications

Automotive

As volumes grow to meet the demands of next-generation transport, automotive manufacturers require more automated quality control to match factory production expectations. AI Reconstruction strengthens Nikon’s assembly line services by boosting evaluation productivity.

Batteries

The rapidly developing battery and electrification industry has growing demands, especially for improved LiB cell performance and safety. AI Reconstruction was designed with LiB cell production challenges in mind as Nikon is already a leading partner for many battery manufacturers.

Aerospace

Efficiency, reliability and safety are at the core of the aerospace industry. So it is important to note that all Nikon’s AI models are trained and validated according to robust processes which ensure that results are reliable and trustworthy for the intended application.

Castings

From castings to machined components and cutting-edge 3D printing, manufactured metals are the backbone of many industrial marketplaces. Any application that requires repetitive scanning can benefit from the speed and image quality improvements offered by AI Reconstruction.

Medical Devices

Medical devices and pharmaceuticals are produced in some of the planet’s most demanding environments, with no room for failure. AI Reconstruction allows users to meet these quality demands, while also offering a higher throughput of sample parts in the lab.

Academic Research

Academic research requires scanning some of the most diverse items, including core samples, fossils, new blends of composites, cutting-edge alloys, and more. AI Reconstruction allows research laboratories of all sizes to process larger batches with more reliable analysis results.

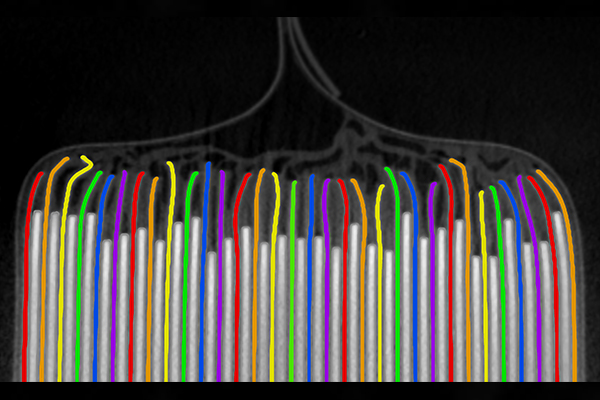

Electronics

From microchips to PCB assemblies, electronic products can be difficult to scan without adequate time. The sector has a diverse range of requirements, so Nikon evaluates client requirements and offers a full solution to meet specific needs, including hardware, software, and analysis techniques.

FAQs

AI Reconstruction enhances CT scans of parts from any industry, from the automotive and aerospace sectors to medical devices and lithium-ion batteries. Any application that requires repetitive scanning can benefit from the speed and image quality improvements.

Nikon developed AI Reconstruction with the European Union’s Ethics Guidelines for Trustworthy Artificial Intelligence in mind. All AI models are trained and validated according to robust processes which ensure that results are reliable and trustworthy for the intended application.

The Deep Learning modelling underpinning AI Reconstruction is trained to tell the difference between useful information and scan artifacts, such as noise and beam hardening. This approach means that fine details retain their clarity while scan artifacts are removed.

Any application that needs better image quality or higher throughput from repetitive scans will benefit from AI Reconstruction. Quality assurance and failure analysis labs can process larger batches with more reliable analysis results, and AI Reconstruction also enables drastically faster production line scans for quality control and closed-loop process control.

AI Reconstruction has been developed to work with any Nikon CT system, including the VOXLS range of industrial CT systems. Nikon’s team will evaluate client requirements and offer a full solution to meet their specific needs, including hardware, software and analysis techniques.

Related, but not the same — both solutions are based on Nikon’s in-house Deep Learning AI knowledge. However, the two products’ goals are different: LiB.Overhang Analysis accurately measures the critical dimensions of anode overhang regions in LiB cells. AI Reconstruction doesn’t perform the analysis, but instead improves image quality so that scans can be easily analysed using industry-standard software. This means that AI Reconstruction has a much broader range of applications.

Related Products

LiB.Overhang Analysis

Limited Angle CT

Speak To Us About This Product

If you would like further details on this product or a more in-depth description, our expert team will provide you with additional information and, if required, arrange an on-site visit.

Talk to us in detail about your project and our experts will advise you on the best inspection system to meet your requirements.

Please fill out the form opposite and we will get in touch with you shortly.