Products and promotions may differ based on your selected region.

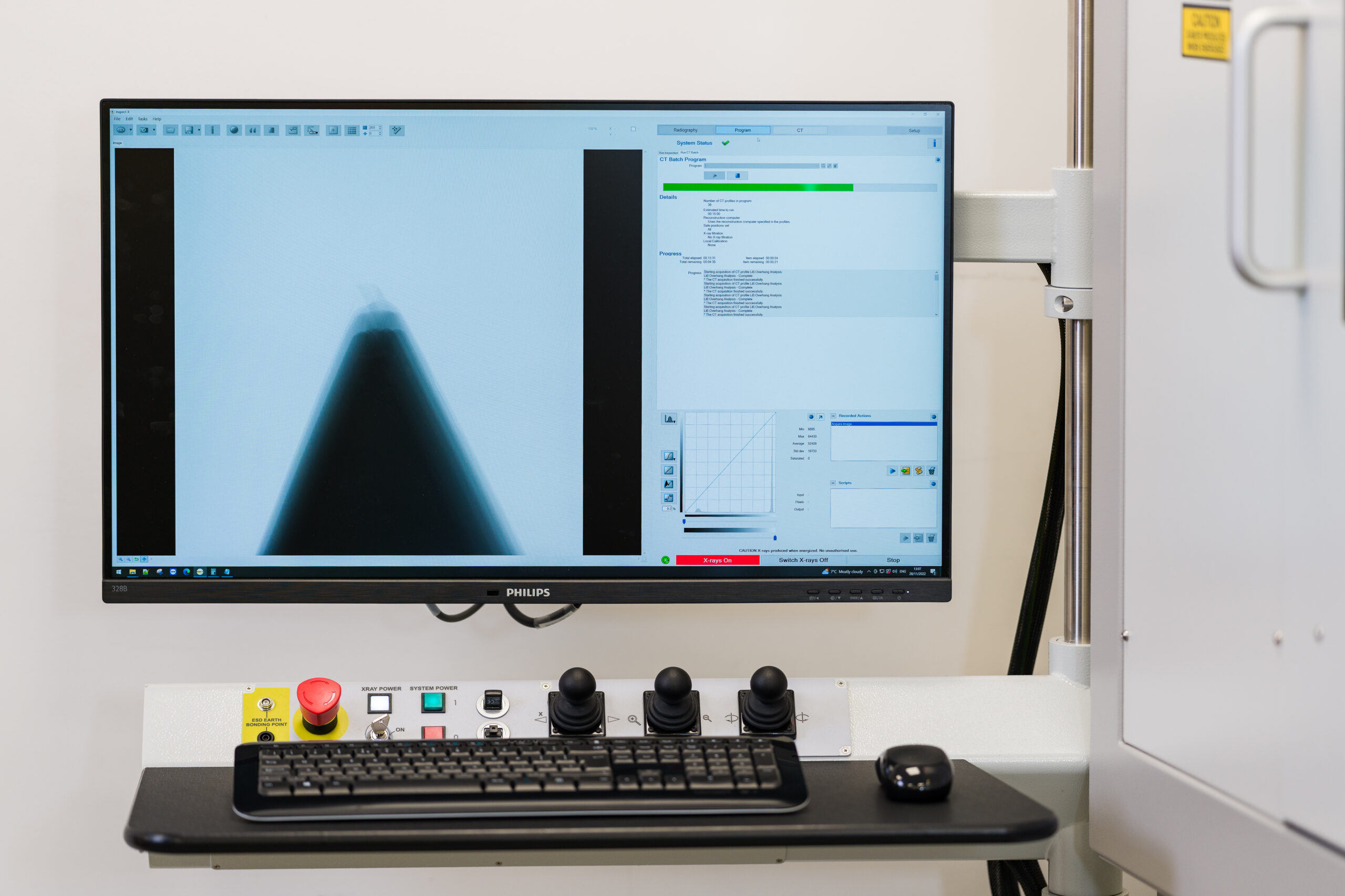

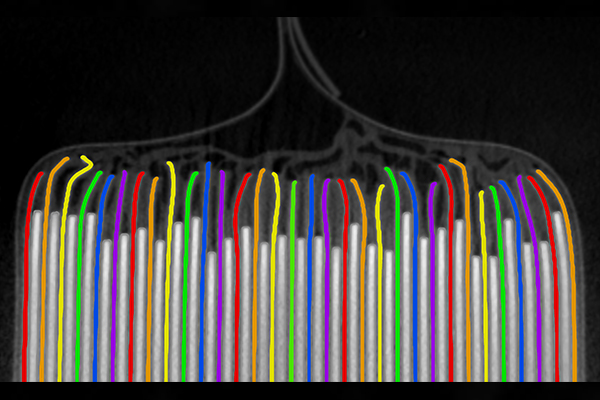

Driving increased reproducibility, automatic analysis gives numerical results from beginning to end – without the need for an operator.

AI analysis technology is tolerant to noise and works reliably, even on high-speed CT datasets.

Machine-readable output for integration with process control systems optimises the production process.