Products and promotions may differ based on your selected region.

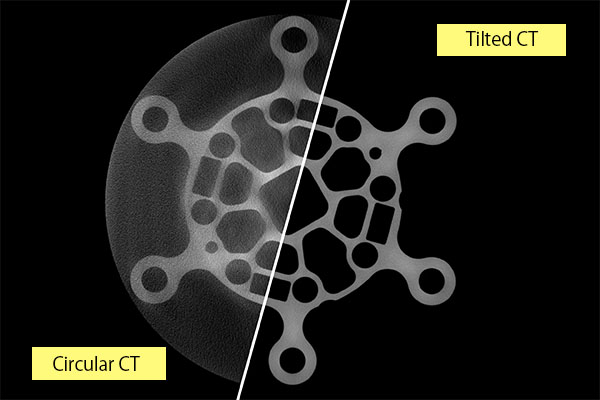

Nikon’s innovative Tilted CT is an X-ray laminography inspection method that uses an angled axis of rotation. It vastly improves voxel resolution for components with a high aspect ratio. Tilted CT produces increased magnification and higher resolution 3D volumes, from thousands of 2D X-ray images.

Fine details previously hidden or masked in traditional CT methods are revealed. Magnification is higher, clarity improves, and data acquisition is faster.

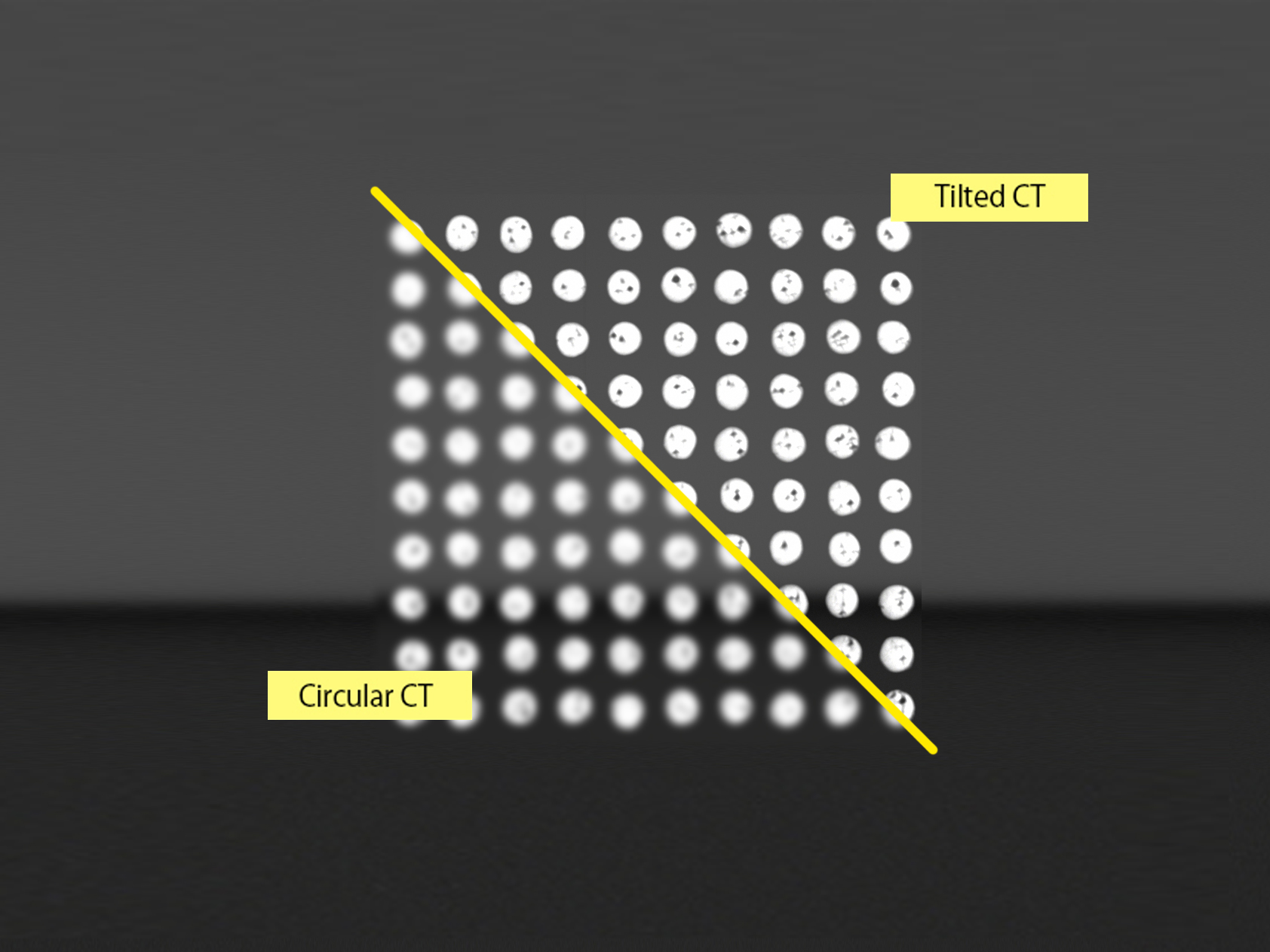

Contrary to conventional 3D CT, Tilted CT uses an angled axis of rotation. As the component can rotate much closer to the X-ray source, it can focus on features which measure only tens of microns even on larger flat components.

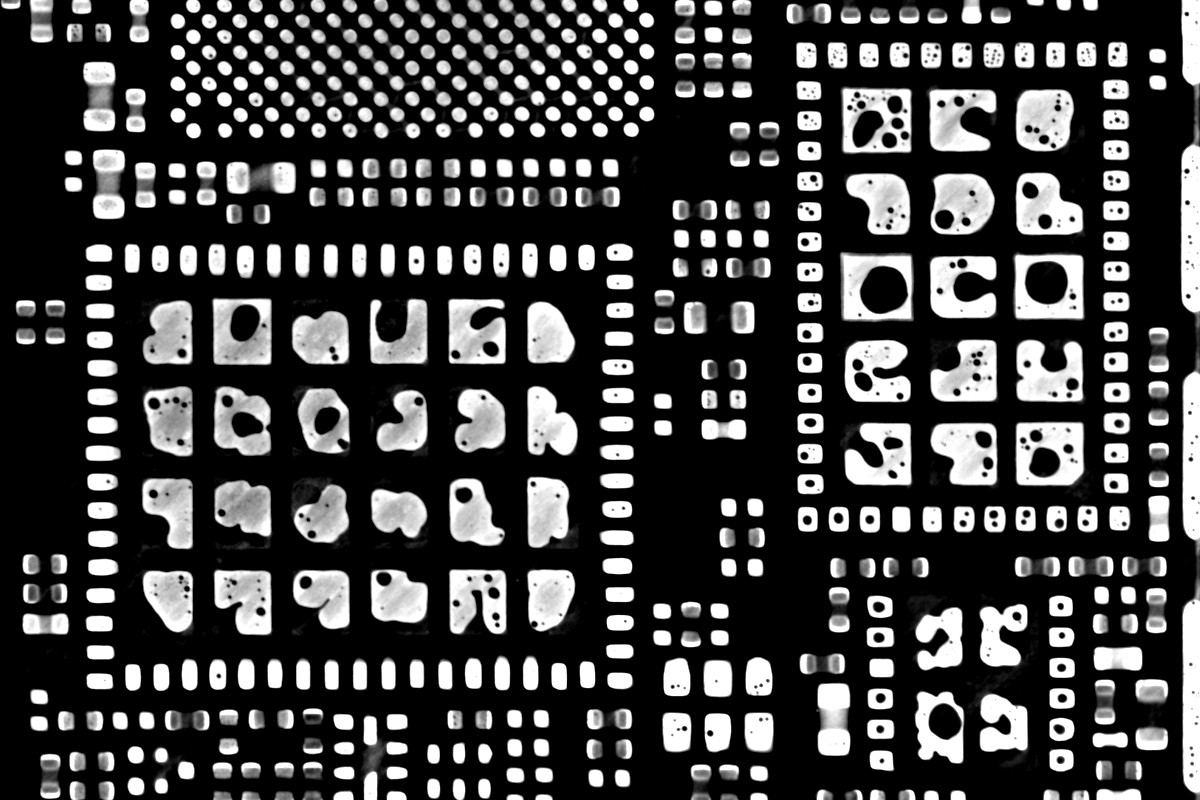

2D slices within Tilted CT 3D volumes enable isolation of components, for clearer non-destructive inspection. Miniscule details and small areas of interest are revealed and can be examined more effectively than with an X-ray radiograph.

Tilted CT provides full, and unhindered views of the component as it rotates through the X-ray cone beam, reducing the risk of overlaying components in complex assemblies or masking from high-density material.

Planar objects can be examined more robustly and efficiently in less time than X-ray microscopy. In one comparative test, a scan using an X-ray microscope took over seven hours, but with Tilted CT it took less than one hour.

Laminography, also sometimes called Computed Laminography (CL), is a type of X-ray tomography where the rotation axis of the sample is tilted at an oblique angle to the X-ray beam (an axis from the source to the detector). In a similar fashion to CT, a laminography scan uses thousands of X-ray radiograph images acquired as the sample rotates through 360 degrees to reconstruct a 3D volume. The same analysis performed on a CT dataset can be replicated on a laminography dataset.

Both radiography and laminography offer very high-resolution images, as samples can be positioned very close to the X-ray source. However, as a 2D technique, radiography does not provide depth to the image and complex samples can be difficult to image due to overlaying components. Laminography, as a tomography technique, maps the depth through hundreds or thousands of planes throughout the sample.

Both are a type of X-ray tomography, but the difference is the orientation in which the sample rotates during the acquisition. The sample rotates around an axis orthogonal to the X-ray beam (an axis from the source to the detector) for CT, whereas for laminography the sample rotates around an axis at an oblique angle to the X-ray beam.

In theory, any size of component can be inspected with Tilted CT, the component size and inspection area on the component would be restricted by the size of the cabinet being used and the practicalities of holding a sample stationary at an oblique angle. A planar sample of more than 0.5m, for example, might become difficult to hold still during the acquisition.

All types of components can be inspected with Tilted CT, but the technique is most commonly applied to planar components. This is because in conventional CT, the large aspect nature of planar components increases X-ray path lengths along the object plane and the size of the component causes the rotation axis to be positioned further away from the X-ray source to avoid collision. Tilted CT overcomes both phenomena, hence its popularity for planar.

Both Tilted CT and X-ray microscopes achieve the ability to produce high-resolution 3D volumes on large samples. While X-ray microscopes can achieve higher magnification that is possible with Tilted CT, their data acquisition times are multiple hours longer than a Tilted CT scan. X-ray microscopes are also a dedicated system, which means they are considerably higher in cost and do not offer all the flexibility that a Nikon X-ray CT system does, with radiography and CT acquisition techniques offering solutions for other applications in the laboratory.

If you would like further details on this product or a more in-depth description, our expert team will provide you with additional information and, if required, arrange an on-site visit.

Talk to us in detail about your project and our experts will advise you on the best inspection system to meet your requirements.

Please fill out the form opposite and we will get in touch with you shortly.