Products and promotions may differ based on your selected region.

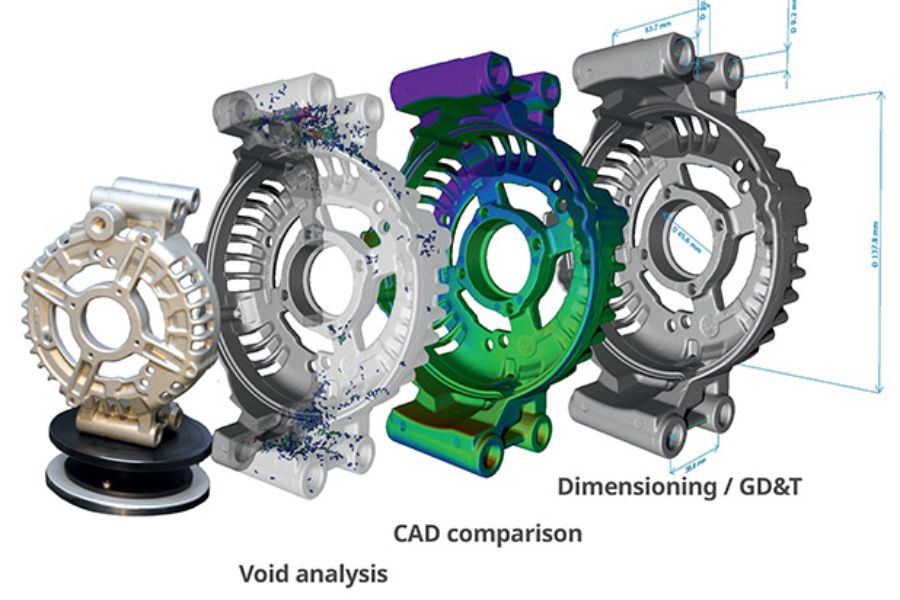

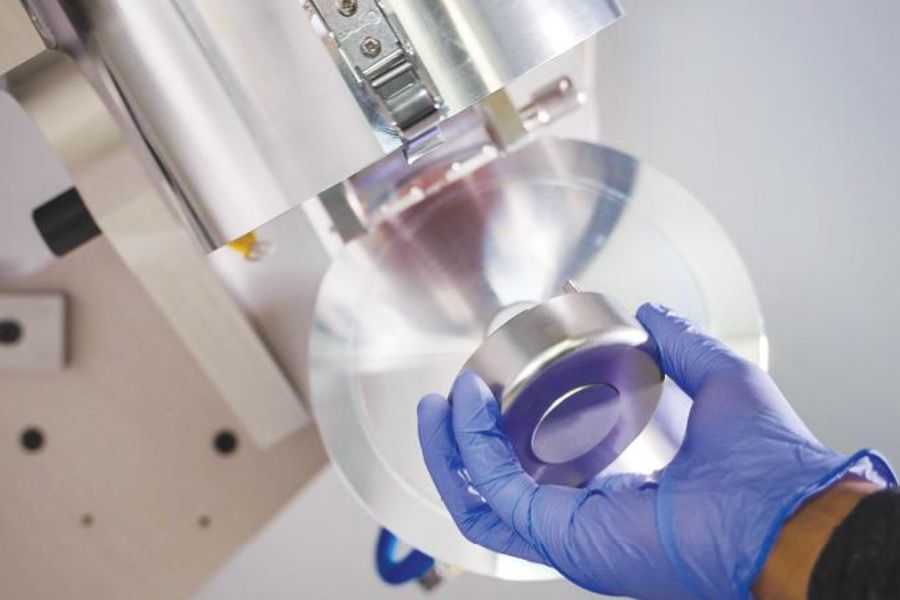

These systems combine the adaptability needed in the lab with unique features like 225 kV Rotating.Target 2.0, Half.Turn CT acquisition mode and Auto.Filament Control to shorten cycle time and improve uptime when used for shop floor series inspection.

With the choice of source, targets, CT scanning strategies and options such as motorised source-to-detector distance adjustment, the XT H systems are versatile and accommodate a wide range of inspection tasks.

Tall objects can be scanned in a single acquisition process, eliminating artifacts introduced by the cone beam and multi-scan stitching. This also provides the added benefit of scanning objects at higher magnification resulting in significantly higher resolution.

Allows continuous operation up to 450W with up to three times higher resolution for the same power, or three times faster data collection for a given resolution.

|  |  |

| XT H 225 For inspection of small to medium parts | XT H 225 ST 2x Flexible system for a variety of applications | MCT225 High accuracy X-ray CT metrology |

| Part size | Part size | Part size |

| Part density | Part density | Part density |

| Accuracy | Accuracy | Accuracy |

| Power | Power | Power |

| Versatility | Versatility | Versatility |

| Footprint | Footprint | Footprint |

If you would like further details on this product or a more in-depth description, our expert team will provide you with additional information and, if required, arrange an on-site visit.

Talk to us in detail about your project and our experts will advise you on the best inspection system to meet your requirements.

Please fill out the form opposite and we will get in touch with you shortly.