Products and promotions may differ based on your selected region.

ECLIPSE MA200 LED

Metallurgical Microscope with Enhanced Usability and Improved Maintenance

MA200 LED applications range from materials research and development to the production and application of innovative materials to the highest quality assurance procedures in metallurgy.

Ergonomic Design Concept

Optimal positioning of operator controls at the front of microscope and a variable angle eye-tube allow fatigue-free work. The stage with a range of aperture plates allows both large and small components and resin-mounted cross sections to be observed. Optical sliders are available for grain sizing and linear measuring tasks.

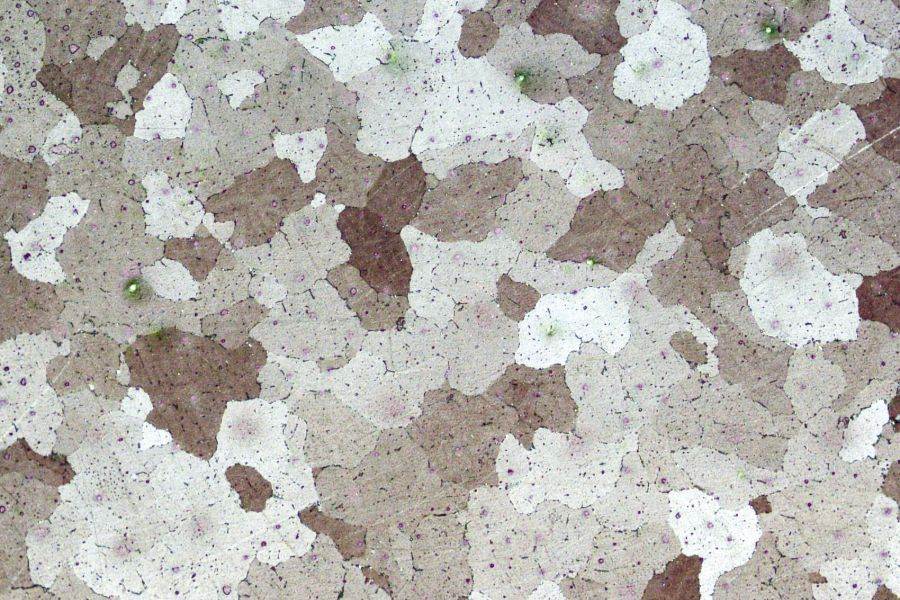

Grain Size and Cast Iron Modules

With NIS-Elements software, operators can conduct Grain Size analysis where grains may be detected and measured according to JIS G0551, ASTM E112-13, E1382-97, ISO643 and GB/T 6394 standards. With Cast Iron analysis, graphite content or graphite-corrected samples can be detected, measured and classified according to JIS G5502, ASTM A247-06 and ISO945-1 standards.

Product Highlights

Digital Sight Series

Used together with Digital Sight cameras for microscopes, high-definition images can be efficiently captured. Images can be processed using the NIS-Elements software to conduct measurement and analysis.

Nikon CFI60-2 Optical Series

Nikon offers various objective lenses designed to match the observations required with the microscopes. Colour aberration correction for the lenses result in greatly reduced colour distortion and excellent image quality.

Wide range of accessories

The latest manual revolving nosepieces achieve stopping accuracy* that is 50% greater than previous models. Other accessories such as microscope stands and LED lamphouses can be selected according to the observation method and purpose.

*Stopping accuracy: amount of change in the FOV when rotating the nosepiece to switch objective lenses and then returning to the original objective lens (e.g., the amount of change in the FOV when switching from 10x to another magnification and then returning to 10x again)

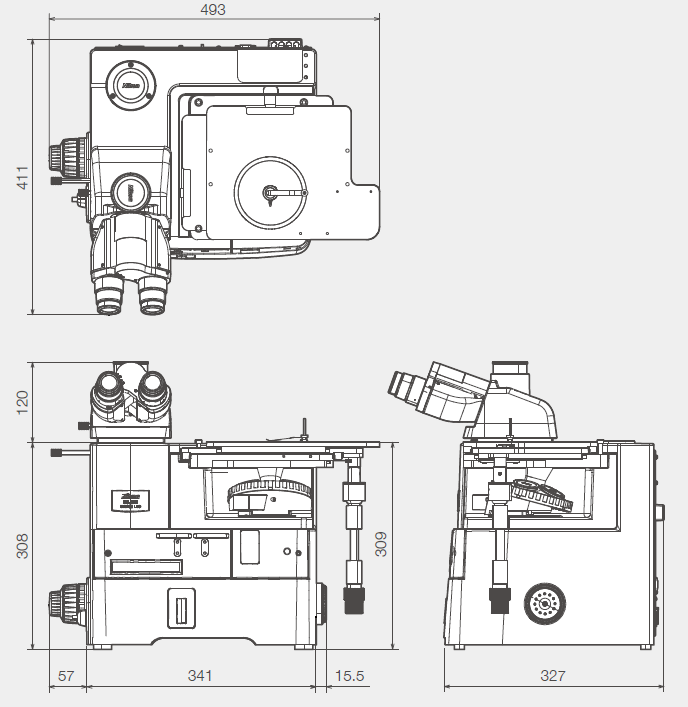

| MA200 LED | |

| Main Body | Focusing mechanism Focusing nosepiece (Fixed stage) Coaxial coarse/fine adjustment knob (torque adjustable) Coarse adjustment of 4.0 mm per rotation, fine adjustment of 0.1 mm per rotation |

| Illumination With flare prevention, Built-in UV cut filter Field diaphragm: dialing continuous variable (centerable) Aperture diaphragm: dialing continuous variable (centerable) Polarizing block (Selectable with or without 1/4 Plate) C-LL-I LED Lamphouse |

|

| Light distribution Eyepiece tube/Back port: 100/0, 55/45 |

|

| Optics | CFI60 /CFI60-2 system |

| Observation Image | Surface Image |

| Observation Method | Brightfield/Darkfield/Simple Polarizing/DIC |

| Resolving Nosepieces | MA-N7-I, LV-NU5IN, LV-NU5A (Motorized) |

| Stage | MA2-SR Mechanical Stage (X/Y flexible handle) Dimension: 295×215 mm, Stroke: 50 mm×50 mm |

| Trinocular Eyepiece | Seidentopf, interpupillary distance adjustment 50-75 mm |

| Power Input | 100-240 V, 50-60 Hz |

| Electrical Power Consumption | 1.2 A 75 W |

| Weight | Approx. 25 kg (depends on combination) |

| Option | Intermediate magnification Turret (1x, 1.5x, 2x), Status detection (Output magnification information to main unit) |

| Scale MA2-GR Grain Reticle (ASTM E112-63 grain sizing numbers 1 to 8), Grid Reticle (20 lines, 0.5 mm) MA2-MR Scale Reticle (compatible with 5-100x, Read in um, Dialing System) |

Related Products

Software

ECLIPSE MA100N

Speak To Us About This Product

If you would like further details on this product or a more in-depth description, our expert team will provide you with additional information and, if required, arrange an on-site visit. Talk to us in detail about your project and our experts will advise you on the best inspection system to meet your requirements. Please fill out the form opposite and we will get in touch with you shortly.