For maximum effectiveness in identifying internal as well as external dimensions, defects, and assembly issues, we want the best image quality delivered fast. Time is critical to achieve results close to real-time so that production line parameters may be optimized as quickly as possible. The result: zero-defect products every time.

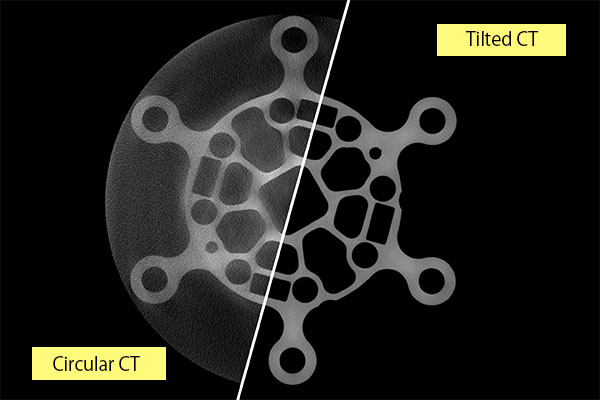

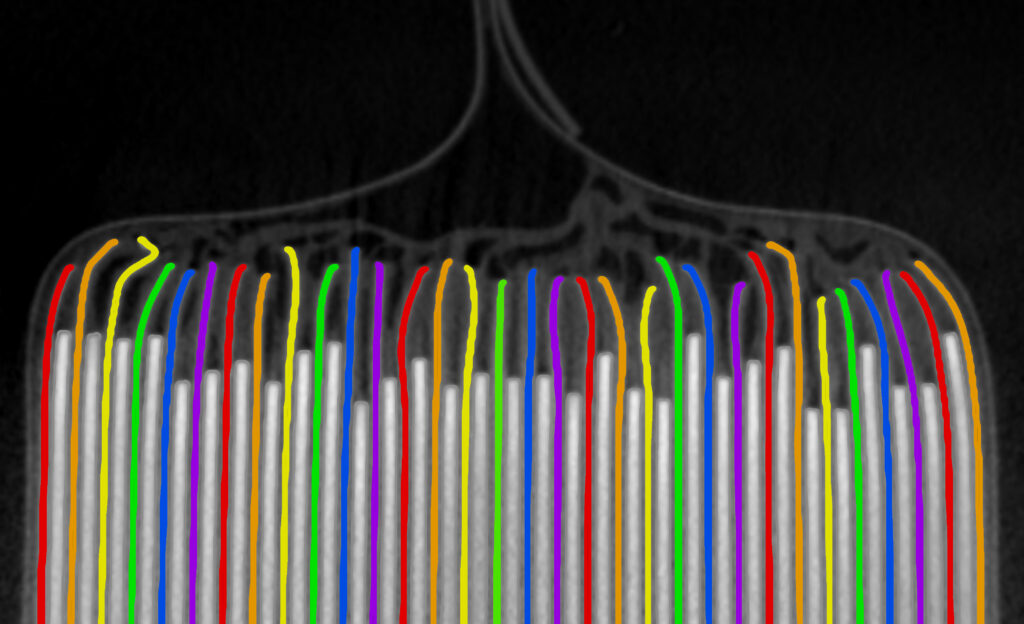

In assemblies of two materials, speed and image quality are usually conflicting requirements. This is because a long scan time is required to generate datasets that are sufficiently clear to be processed, which is contrary to the requirements for real-time inspection. Assemblies of two materials often lead to long scan times and severe image artifacts – but not with the latest X-ray CT solutions from Nikon thanks to our new reconstruction technique, which we will present to you.

In this webinar, you will learn about why dual material samples are problematic to achieve Quality 4.0 and new solutions to the problems.

We intend to focus in detail on three key areas – traditional reconstruction techniques, Dual.Material CT and Nikon’s toolbox for reducing X-ray CT scan time.

Visit the product page for additional information and to download product literature.

If you have further questions or would like to speak to us directly, feel free to contact us.