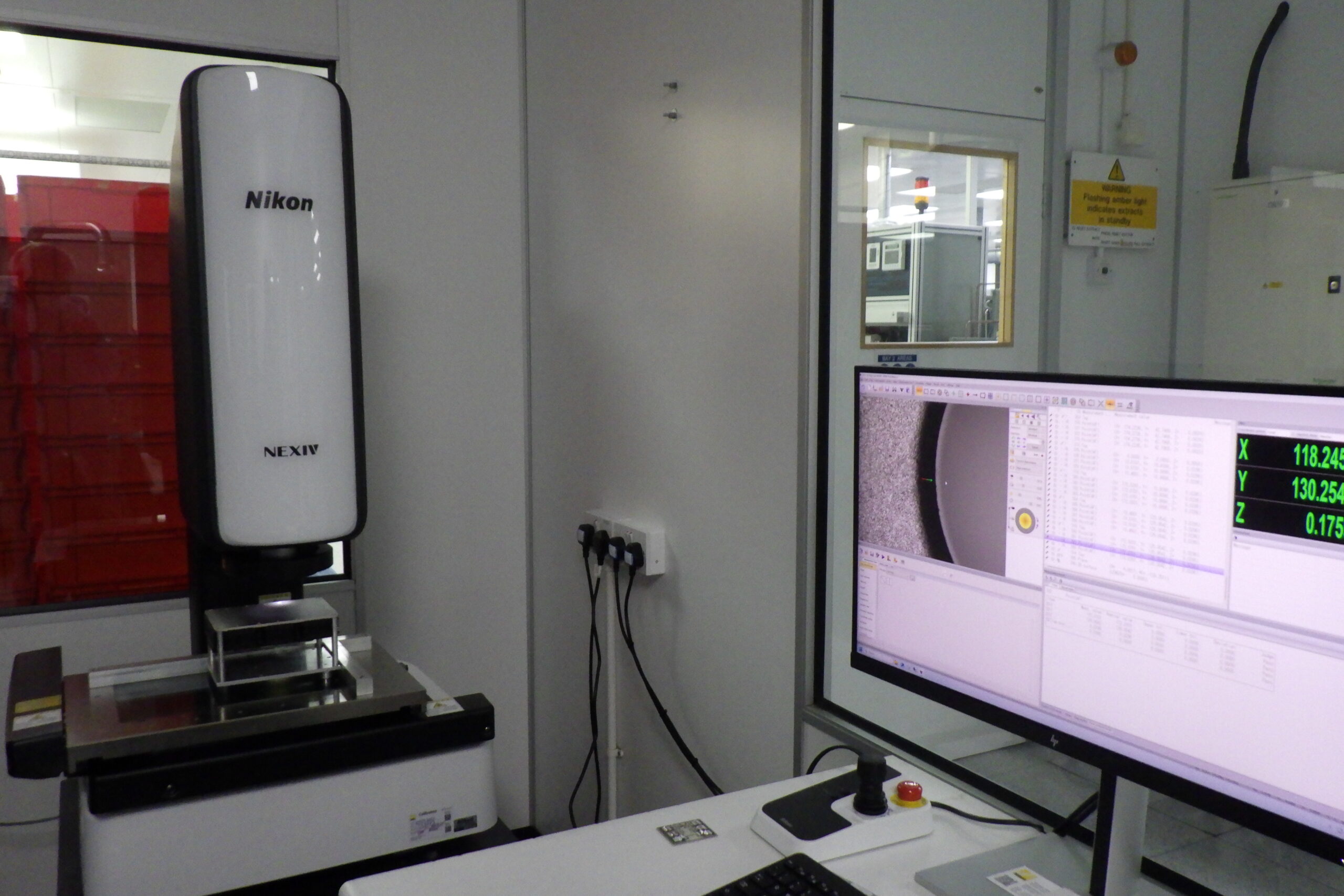

Dynex Semiconductor Ltd, a pioneering company founded in the 1950s and based in Lincoln, England, has a long-standing reputation for designing, developing, and manufacturing high-power semiconductor modules and power assemblies. Their expertly designed bipolar capsule devices, IGBT modules, and power assemblies are used in various power electronic systems. Committed to energy efficiency and environmental impact, Dynex aims to deliver optimal outcomes with minimal waste. To uphold its high production standards, Dynex selected Nikon’s market-leading NEXIV VMZ-S3020 video measuring system.

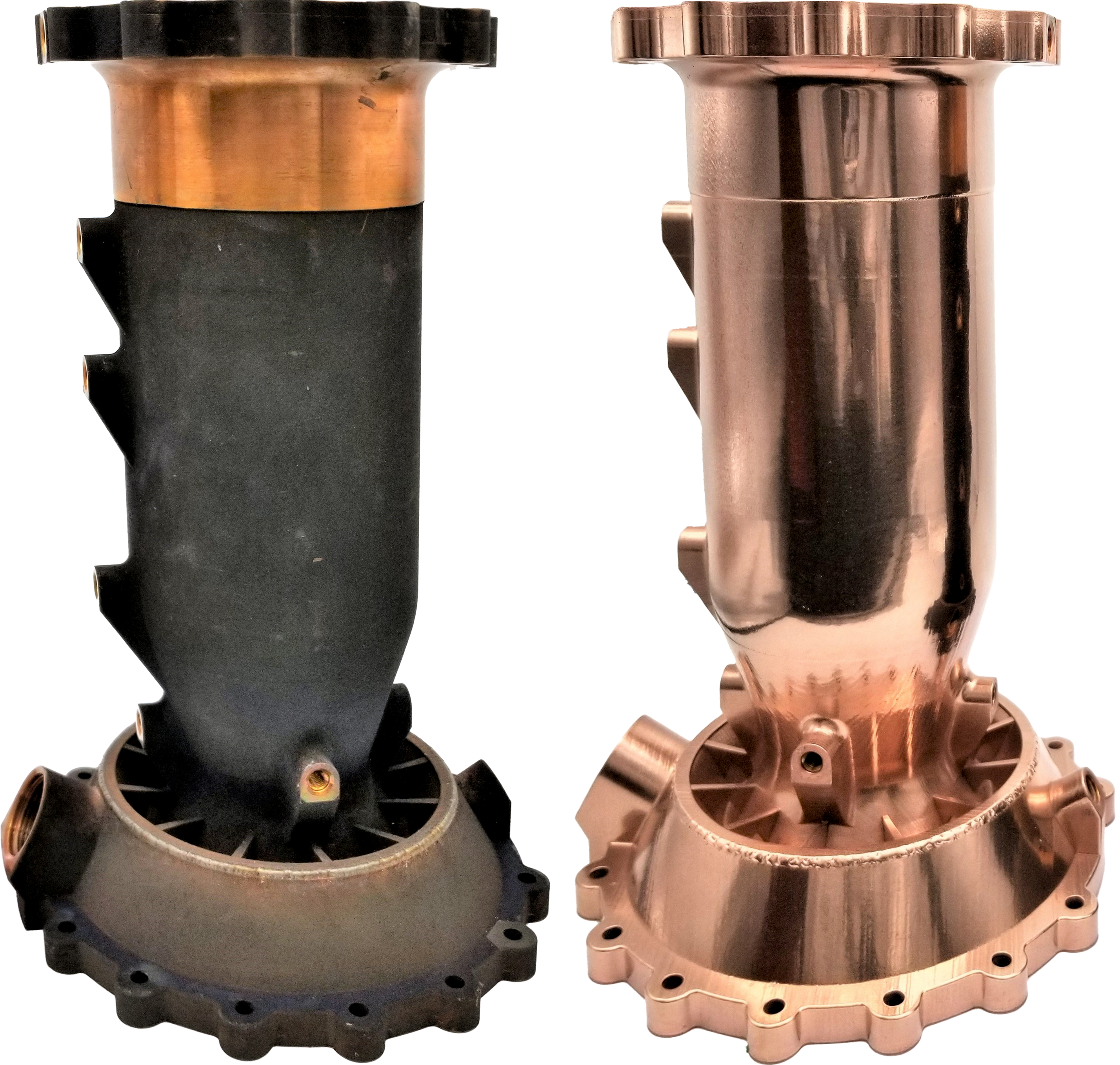

High-power semiconductor modules, such as IGBTs (insulated gate bipolar transistors) that handle voltages typically up to 6500V and currents as high as 3600A, generate significant heat that must be effectively dissipated during operation. Crucial to this is the base plate on which the electrical components are assembled. It attaches to a heat sink and must form a good thermal interface of uniform thickness, without trapped air (which is a poor thermal conductor) or other defects that could lead to hotspots, high junction temperatures and reduced reliability. The plate is therefore manufactured with a slight curvature, convex in the direction away from the electronics, so that it may be bolted to the heat sink reliably in six places at a predetermined torque to ensure it lies absolutely flat.

The NEXIV systems at Nikon Metrology, part of the Industrial Solutions Business Unit (IDSBU), ensures that products manufactured by Dynex Semiconductor do not suffer from such air pockets and resulting performance degradation or module failure. Quality control (QC) of the curvature, or bow of the aluminium-silicon-carbide metal matrix composite plates is now being managed with the help of a Nikon NEXIV VMZ-S3020 Type 2 video measuring system, which was purchased and installed in mid-2024. The result is that manufacturers using Dynex products for electric vehicle, renewable energy, industrial drive, railway traction, electrolysis and similar power-dense applications can be assured of long-term reliability and peak performance.

The curvature of the plates is up to 500 μm between the centre and the edge, a dimension that must be held to a tight tolerance during manufacture. The original method of QC at Dynex was to use a touch-probe to check positions manually across the curved surface. However, the process was slow and could not measure individual locations in 3D space to better than ±10 μm. That was prior to 2012, when Dynex invested in its first Nikon NEXIV, a model VMR-3020, which transformed the inspection process by being able to measure vastly more points on a 1 mm grid across the entire surface of the plate, fully automatically, well within tolerance. As well as being a more precise metrology tool, it gave a better holistic evaluation of the overall shape of the plate.

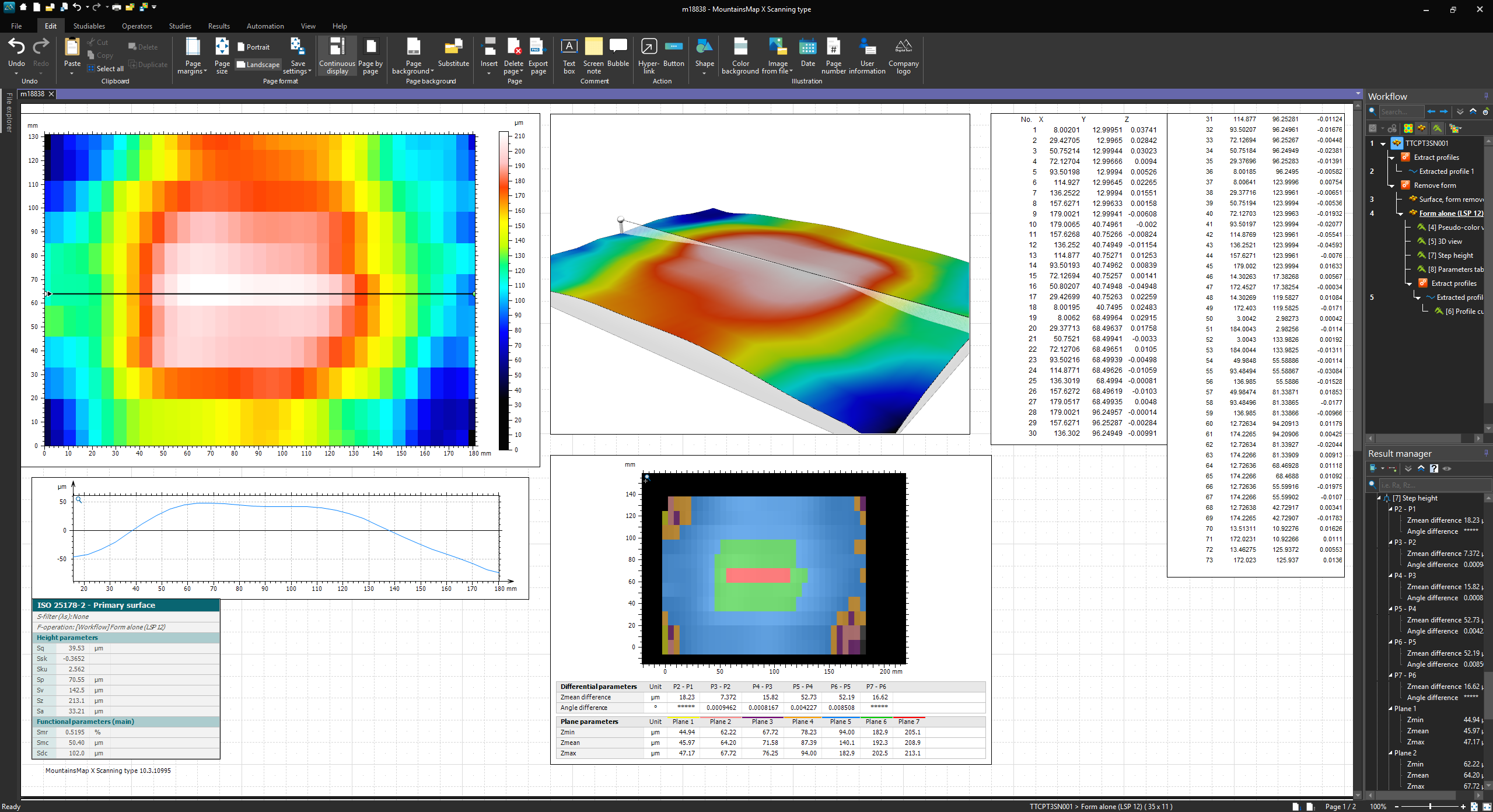

Twelve years later, the successor model VMZ-S3020 replaced the VMR at Dynex, further improving quality control and making it more useful for research and development activities and troubleshooting occasional problems on the production line. For the latter, written reports and coloured heat maps are produced for factory staff so that remedial action can be taken as required. The VMZ-S3020 has double the magnification at 540x, offering high-resolution observation as well as a wide field-of-view and a long working distance. It is also typically 50% faster in operation and has better accuracy.

Mark Addlesee, Project Manager at Dynex commented, “We purchased the initial NEXIV after an exhaustive review of at least seven potential metrology equipment suppliers. Owing to the excellent performance of the equipment for more than a decade and the good training, service and ongoing support provided by the supplier, we selected the upgraded inspection machine last year with no hesitation.”

The latest NEXIV is so quick at inspecting the base plates that spare time on the instrument is already being employed.”

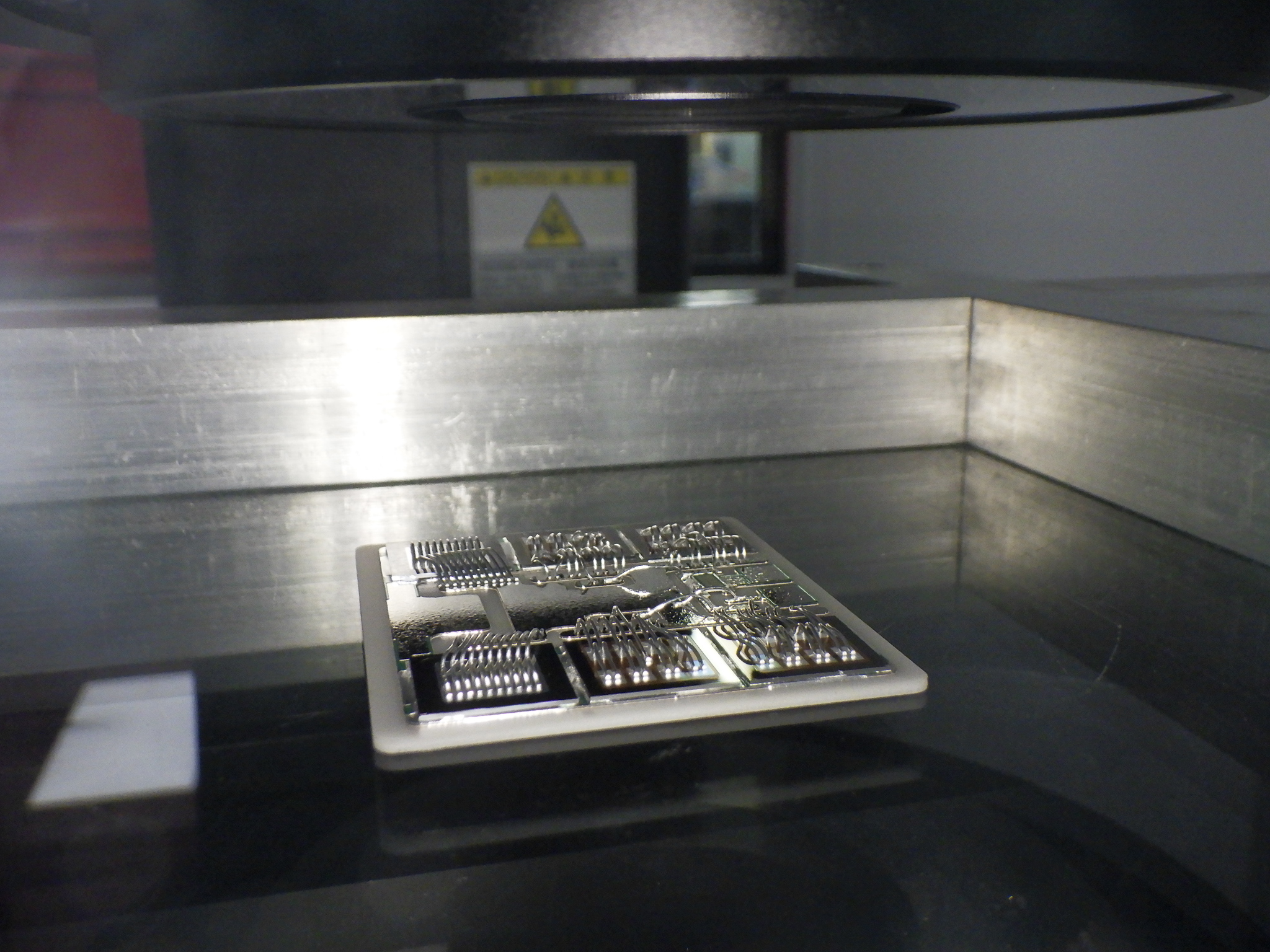

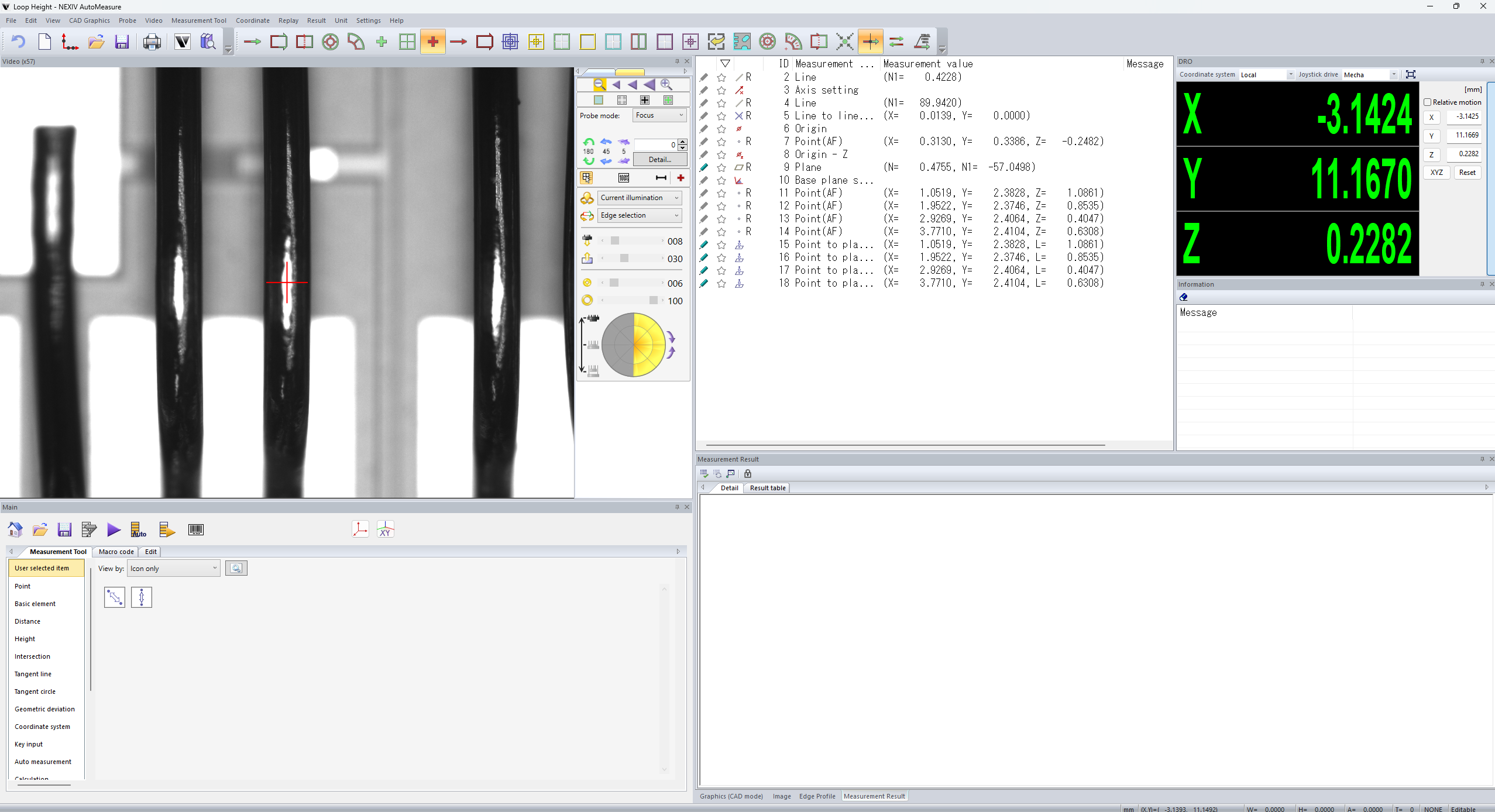

Nikon’s NEXIV VMZ-S3020 Type 2 video measuring system deliver advanced 2D and 3D optical measurements for diverse industrial needs. In this application, rather than only measuring features in X and Y, it positions the stage repeatedly under an optical head in the horizontal plane with the help of the proprietary, high resolution linear encoders and uses an advanced through-the-lens (TTL) laser auto focus (AF) system to determine the height at each point. The laser beam is projected directly through the same high-quality Nikon objective lens used for image capture on the high-resolution CMOS sensor of a digital camera, in this case a black and white model. Similarly accurate movement of the head in the Z-axis determines when the reflected laser beam is in focus and thus the height of the component under investigation at that point.

The base plates being inspected at Dynex generally measure from 140 x 190 mm down to 70 x 137 mm. High resolution scans at 1 mm intervals take up to one hour, but if a more cursory check is sufficient, at say 15 mm intervals for example, the measuring process is significantly accelerated. The high speed of the NEXIV lends itself to the required rapid acquisition of data by Nikon’s AutoMeasure software, which handles basic 2D dimensional and 3D height measurements.

For more advanced evaluation of the point heights and surface topography, the CSV data is transferred into a seat of MountainsMap surface analysis software from Digital Surf. Mr. Addlesee pointed out that this data format also links well with Dynex sales presentation software. Taylor Swain, Process/Development Engineer at Dynex, is likewise keen on the Nikon Note multimedia software integrated into AutoMeasure, which acts as a support and training tool and allows operations to be streamlined.

The latest NEXIV is so quick at inspecting the base plates that spare time on the instrument is already being employed. For example, the 13.5 mm square dies (semiconductor chips) of IGBTs are examined on the fly to establish that the pitch and height of the wire bonded soldered to the substrate are within tolerance. Smaller packages such as resistors that use screen-printed solder are checked for wire bond flushness. Another QC application recently carried out by Mr. Swain involved a 0.5 mm grid scan to characterise the flatness and parallelism of a new supply of 50 mm diameter upper and lower lids for bipolar thyristor parts. Other engineers within the factory are asking about the possibility of investigating the planarity and circularity of components, which is well within the NEXIV’s remit.

A particularly advantageous feature is the comprehensive illumination, which can be fine-tuned to scan even the most problematic surfaces at Dynex, including those having high reflectivity. In addition to episcopic and diascopic lighting, there is twin-ring LED illumination around the objective lens, with eight segments that are independently adjustable to alter the incident angles to optimise contrast, minimise glare and emphasise features on the component under inspection. In the primary use case at Dynex using TTL laser AF, the laser operation is light-independent but the illumination helps to align the component before measuring starts.

Mr. Swain commented, “I have frequently used and appreciated the stitching profiles in the NEXIV software when taking high magnification micrographs in certain areas so they can be combined into a single, high-definition image of an area of interest. In one instance, we had silicone oil bleed out from a glue, and it helped to define the problem and determine its solution.”

Mr. Addlesee concluded, “The latest NEXIV and indeed its predecessor has a raft of different metrology and inspection functionality, we have only begun to scratch the surface of the NEXIV capability. Nikon is more than receptive to helping us at training days and other events to expand our knowledge and our use of their equipment into other suitable applications, and we are very much looking forward to the ongoing collaboration.”