In 2023, Kataras CNC Machining, Acharnes, Athens, welcomed their Nikon NEXIV VMZ video measuring system. Kataras CNC Machining have been top players in high-precision parts and molds manufacturing since their incorporation in 1985, but needed a new solution which would meet their exacting demands in terms of quality control and faster measurement.

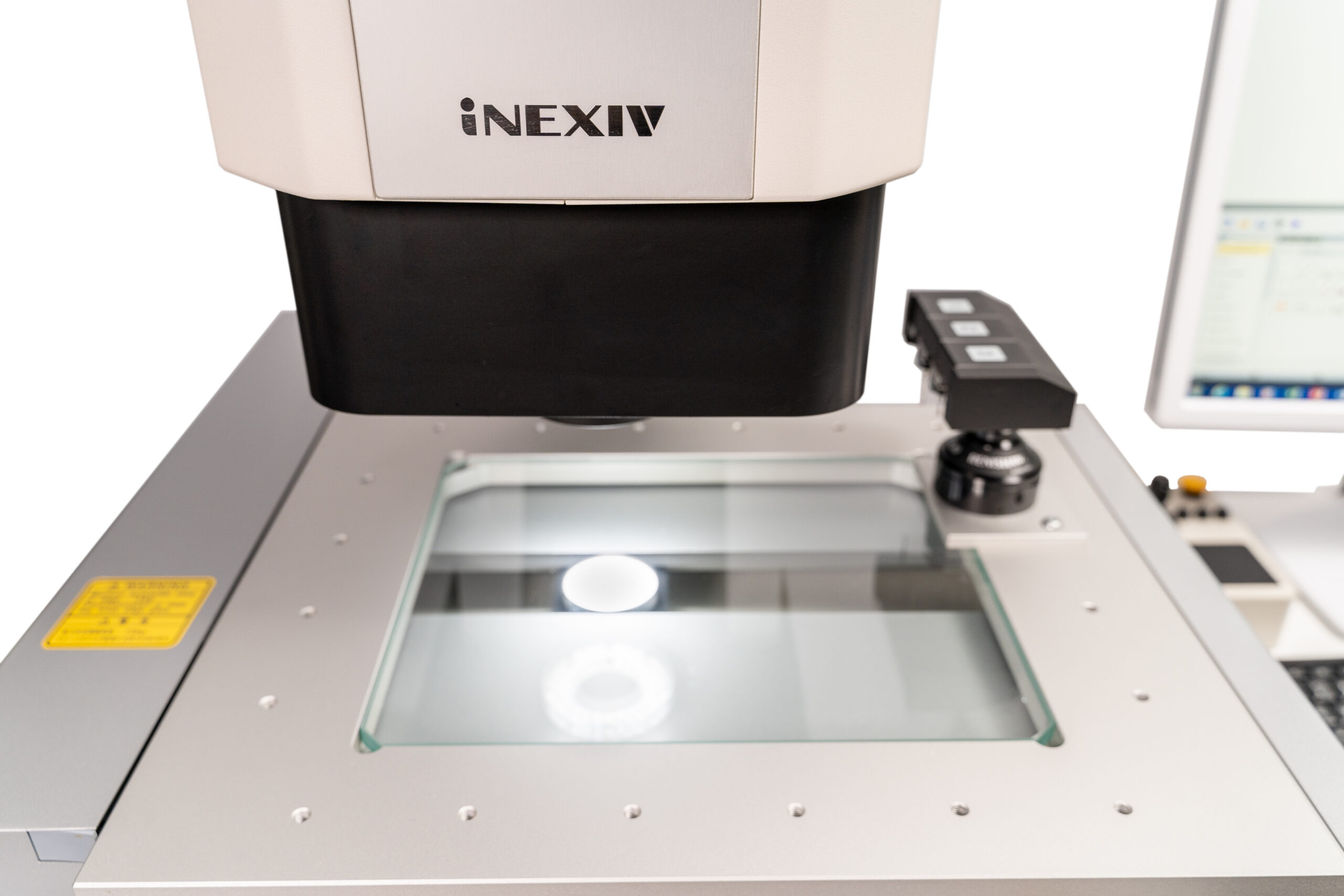

Nikon Metrology’s NEXIV VMZ video measuring machine installed at Kataras’ facility in Acharnes, Greece

Previously, Kataras had used traditional CMM machines to carry out the day-to-day measurement tasks. However, with increasing demand and higher-precision requirements, they realized the CMM had limitations, particularly when measuring detailed parts of up to 0.5 mm. The traditional CMM process took a comparatively long time to measure each part (especially when high-precision was necessary), and they needed more highly skilled operators to ensure they met accuracy and precision requirements. All adding valuable time, resource and costs to the measurement process.

To maintain their reputation and position as precision CNC manufacturers, Kataras had continuously invested in modern CNC equipment and software, increasing the quality, speed and efficiency, as well as providing the best solutions for their customers. They had already integrated CMMs in many stages of the production process. However, they were working on new projects which demanded higher accuracy and faster measurement speeds.

Additional requirements included:

- High volume of parts measurement

- Part size: 0.1 mm

- Accuracy: +- 2 μm

- Flexibility of measurement adjustments in each production phase, including moving from EDF to 5 Axis CNC processing several times per part

- Short delivery time

The Nikon NEXIV VMZ met all of their requirements, providing a complete upgrade for all their procedures.

Since installing their first Nikon VMZ series, they have seen the measurement cycle time reduce by 70%. Improvements in part programming efficiencies have also removed the need for complex measurement routines, so they need fewer operatives and resources for each part.

Beneficial features include:

- High accuracy, high-speed measurement with through the lens (TTL) laser AF

- Easy to use, streamlined software suite

An operative using Nikon Metrology’s NEXIV VMZ video measuring system at Kataras CNC Machining, Acharnes, Greece

The team at Kataras were equally impressed by Nikon’s after-sales service and support, as they were with the excellent performance of the NIKON NEXIV VMZ. During the training provided by Nikon Metrology, Kataras also gained technical knowledge of the instrument features, process controls, and operating and analysis techniques. The Nikon VMZ has provided them with a truly automated measuring process and contributed to continuous improvements in future manufacturing procedures.

Further details about NEXIV VMZ-S are available here.

About Kataras CNC Machining:

Based in Acharnes, Athens, Greece, Kataras CNC Machining has been operating since 1985. They specialise in manufacturing high-precision parts and molds. They provide highly accurate parts for their customers.