It is difficult to think of a more challenging inspection task than to use an optical microscope to investigate the distribution of additives and modifiers after they have been incorporated into bitumen. They are routinely introduced to give the material specific characteristics for diverse construction projects to optimise functional, economic and environmental performance. Advantages in paving and roofing are numerous. For example, the addition of polymers, fibres, fillers and other agents to alter the morphology of bitumen can raise durability and longevity to reduce the frequency of repairs, improve application techniques to minimise wastage, or realise a permeable built environment with enhanced drainage properties.

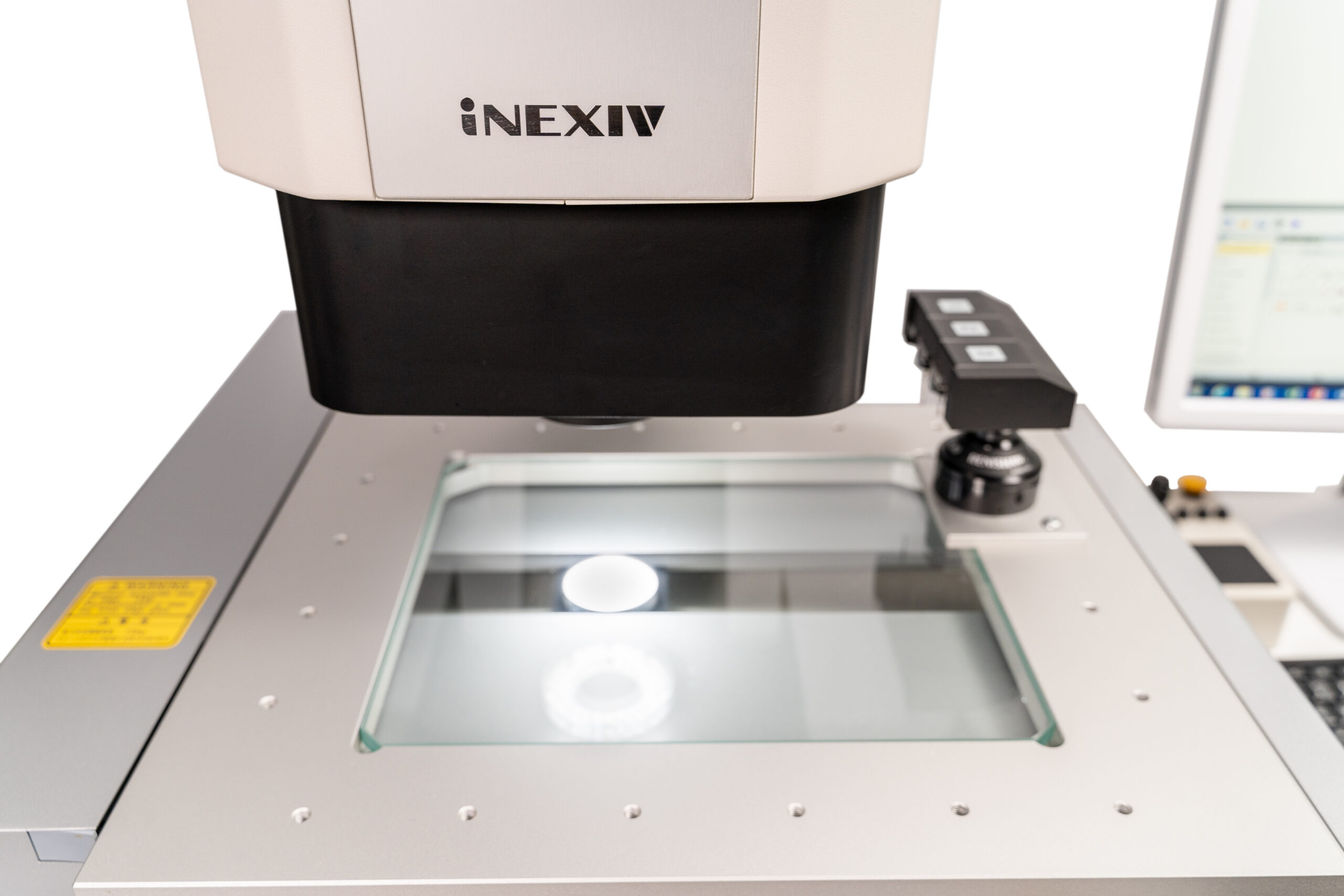

The Industrial Solutions Business Unit of the global Nikon Corporation is therefore proud to have helped improve quality control in this area to a considerable degree in collaboration with one of its customers, WISTEMA, a German specialist in bitumen additives and modifiers, headquartered in Dielheim, Germany. Remarkably, this association has been in place for more than 35 years.

After various ingredients, particularly polymers such as SBS (styrene-butadiene-styrene) and APP (atactic polypropylene), have been incorporated into bitumen, they significantly upgrade its intrinsic properties, including enhancing resistance to rutting, reducing cracking in low temperatures, and improving adhesion. However, it is important to understand the influence of the mixing conditions, such as temperature and time, on the additives’ dispersion and interaction with bitumen, in order to optimise manufacturing parameters to achieve the ideal structure and performance. Uniform dispersal of the extra materials throughout the matrix is desired, whether they manifest as globular or dendritic, while agglomeration must be avoided, as it creates weak points that would compromise the bitumen’s integrity.

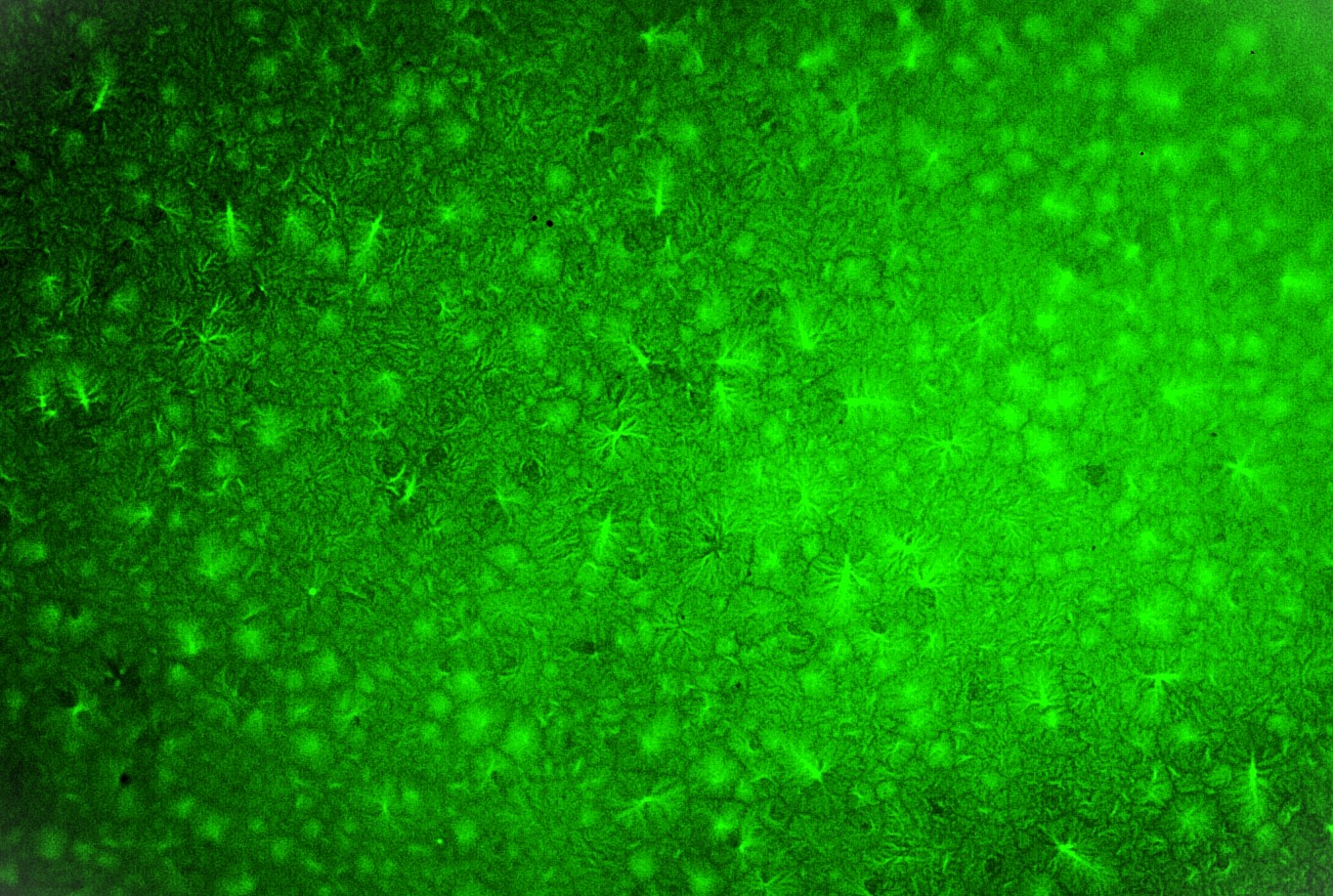

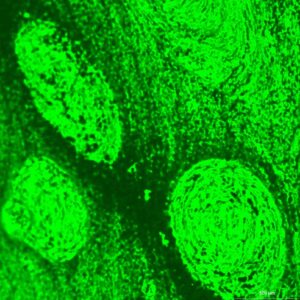

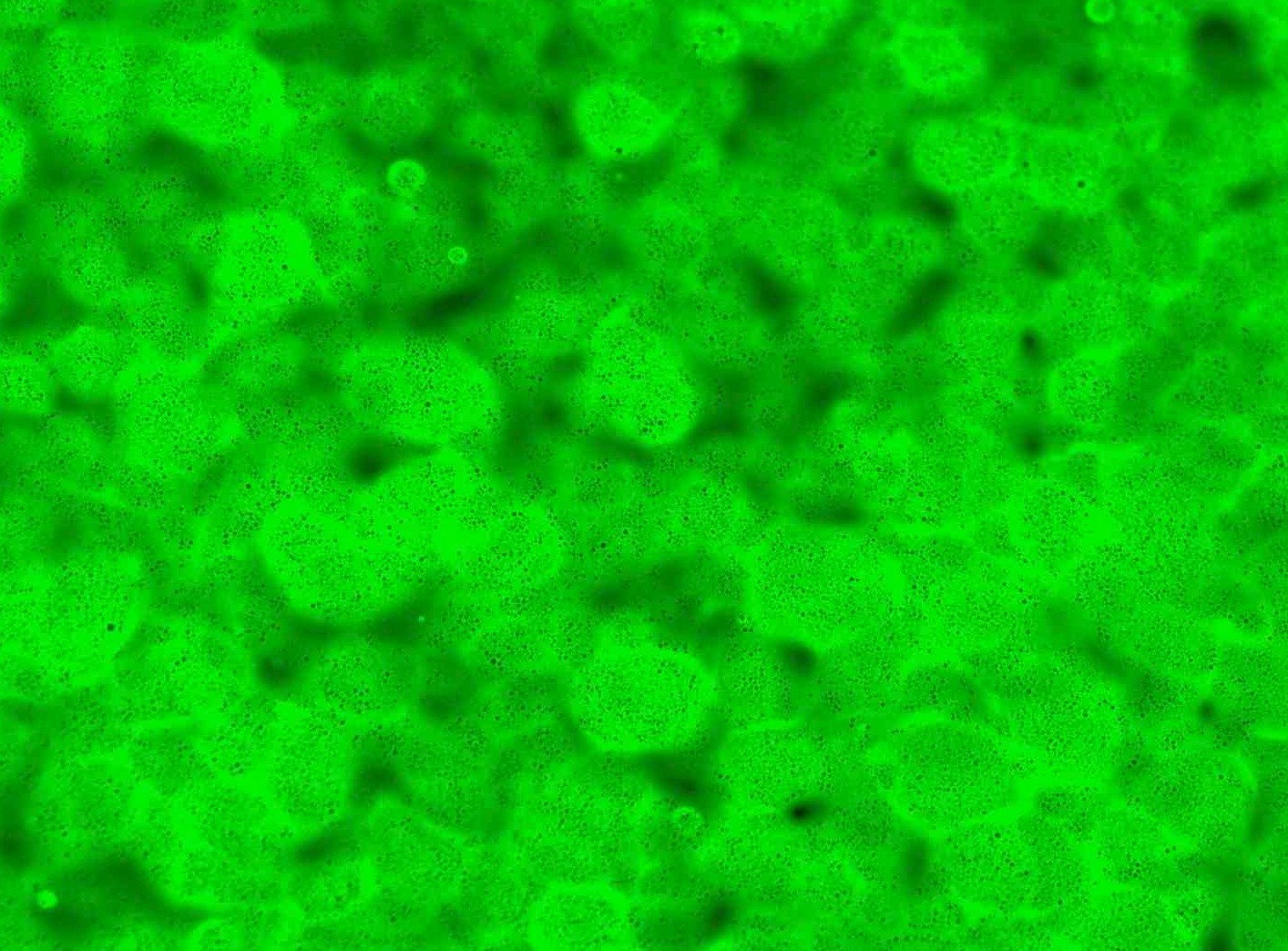

WISTEMA’s use of fluorescence microscopy equipment supplied by Nikon to examine the physical characteristics of bitumen after it has been processed with additives is a sophisticated line of scientific enquiry. A sample of the material is sectioned and the surface that was previously on the inside is viewed under high-frequency incident light to learn how the additional ingredients have been dispersed. Luckily, many of the polymers either inherently fluoresce, or can be chemically modified to do so when exposed to specific wavelengths of light. Conversely, bitumen itself typically exhibits very weak or no photoluminescence of any type. The difference in properties allows researchers to visually distinguish the bitumen, which appears dark or black in an image, from the polymer-rich phase, which glows. The Nikon fluorescence microscope is able to capture these emitted photons, generating an image that reveals the shape, size and distribution of the inclusions within the host matrix.

The core commercial focus of the international WISTEMA organisation lies in developing and supplying the sophisticated ingredients that enhance the function of bitumen across its numerous applications. The company has to verify mixture integrity meticulously, not only immediately following production but also after the material has undergone various types and degrees of aging. The inherently opaque nature of bitumen has always presented a significant obstacle to any form of direct visual analysis. Normally when developing and testing new blending combinations in an R&D laboratory, the surface of a cross section of bitumen superficially looks black, with no discernible physical features. Over the past three decades, Nikon has consistently risen to meet this challenge, continually evolving and refining its microscopy technology to align with and indeed surpass the increasingly demanding analytical requirements of companies like WISTEMA.

In the mid-1990s, Nikon’s fluorescence microscopes equipped with an arc lamp for illumination and a film camera gave WISTEMA its first opportunity to visualise the fundamental mixture quality imparted by common modifiers. At the time, trials on bitumen samples carried out by three other potential instrument suppliers failed to produce usable pictures – essentially, they were just black. Nikon’s pioneering microscopes, despite their own limitations, were capable of revealing dark yet distinctly discernible fluorescent images. This initial albeit rudimentary success proved pivotal, igniting a much deeper curiosity within WISTEMA and fostering a desire for even greater insights into bitumen’s enigmatic properties. The ability to even faintly perceive the distribution of the crucial additives marked a significant improvement over previous indirect analyses, setting the stage for future breakthroughs.

More than a decade later, in about 2010, Nikon introduced a new generation of fluorescence microscopes, which brought with it a transformative leap in observational capability. The advance was inspired by a pressing need in the metal processing industry, especially in the steel sector, for better optical metallurgical inspection and precise examination. It is an area where Nikon is particularly strong, having developed ultra-sensitive digital microscopy systems that produce strikingly clear images when using darkfield illumination. The refined setup dramatically enhanced visibility, allowing much clearer and more nuanced differentiation of the intricate bitumen structures. The progress in imaging was primarily attributable to the integration of a Nikon black and white, full-frame digital camera of very high sensitivity (which incidentally also eliminates the time-consuming requirement to develop film and print photos), coupled with a greatly improved source of illumination powered by light emitting diodes (LEDs).

The pictures are stunning. They are sharp and clear, and we are continuing to learn how to interpret them. Understanding in detail what is going on allows us to devise new combinations of ingredients.” – Bitumen expert Marc Beuken, a consultant to WISTEMA

This advance enabled WISTEMA to explore cutting-edge bitumen mixtures containing additives constituting as little as 5% by volume (rather than 20% or more) capable of producing a novel, twin-phase structure. The idea was to create an alternative to blown bitumen, which undergoes oxidation at high temperature to impart strength, durability and heat resistance. However, the process is detrimental to health and safety. It is suspected of forming carcinogens and is certainly not environmentally friendly, while the high temperatures involved present the risk of burns to operatives. Clearly there was much incentive within the industry to investigate alternatives.

Normally, bitumen has a relatively low softening point of between 45 and 55 degrees Celsius. The considerable heat from a concentrated beam from the arc lamp on the first Nikon microscope, which was necessary to see the required detail, started melting the material within seconds. It severely curtailed inspection of the multi-phase structure that in theory was effective, but without pictures was impossible validate. In comparison, cool LED lighting extends the time the specimen can be under the microscope for examination, giving more opportunity for analysis.

Most recently, WISTEMA came up with yet another intriguing challenge, sending three distinct, unidentified bitumen samples to Nikon, each with just 3% by volume of different polymers. When Dr. Peter Callsen, Area Sales Manager at Nikon Metrology in Düsseldorf, initially undertook microscopy trials, at first there was nothing to see. By testing various illumination techniques and cameras, he was able to capture photographs of the microstructures in the specimens, despite there being the ongoing problem of the material melting, although not so quickly as before. New this time was the provision of Nikon’s NIS-Elements software that, in an easy-to-establish workflow, allows the captured images to be digitally enhanced to improve the contrast and to reveal features in simulated 3D. It enables, for instance, a spherical inclusion to be perceived and measured, whereas previously it just appeared as a flat circle. The software version WISTEMA is using is NIS-Elements BR (Basic Research), which allows quick and easy interactive measurement of single objects with automatic edge detection as well as automated recognition and measurement of distribution, sizes and other features of a great number of particles.

Bitumen expert Marc Beuken, a consultant to WISTEMA said, “We can now see not only diverse sizes of ballon-like inclusions, but also what surrounds them, which helps a lot in establishing what is happening in the interior of the material. We can also see the dendritic crystallised structures that result from some of the additives.”

“The pictures are stunning. They are sharp and clear, and we are continuing to learn how to interpret them. Understanding in detail what is going on allows us to devise new combinations of ingredients to develop yet more formulas that WISTEMA’s customers can use to make even better bituminous products.”

Successful completion of the trials by Dr. Callsen led directly to the acquisition of a modern Nikon LV150NA microscope, configured with advanced fluorescence illumination and delivered with two specialised filters for blue-violet and blue excitation. The filters each permit a specific emission colour to pass, while blocking the shorter excitation wavelength. Three photographs are taken of a sample – one showing the black and white surface, plus extra images of the pair of ingredients, which show as two different colours so they can be distinguished from one another. By using filtration in this way, the previous, time-consuming need to adjust the wavelength of the excitation light is avoided.

Dr. Michael Schukin, regulatory affairs manager at WISTEMA, who is currently helping to set up a new bitumen research function in the R&D centre at Dielheim, confirmed that two other potential microscope suppliers were offered the chance to tender, but as before were unsuccessful in being able to show any satisfactory images. He also mentioned that the latest Nikon microscope, which was delivered at the beginning of June 2025, is very easy to use, many functions being automatic, including focusing. After training was completed, operators were able to use the equipment with complete confidence within one to two weeks.

Lars Friedel is a second-generation director of WISTEMA, a family-owned business started in 1990 by his parents, Winfried and Helena, to look at the side stream (and waste stream) from petrochemical sector operations, bitumen being the heaviest fraction remaining after crude oil undergoes distillation. In conclusion he commented, “Although over the years we have branched out into different areas of the chemical industry, additives for bitumen remain the largest part of our activities.

“We have always been at the forefront of this technology over the years, thanks to the superiority of Nikon’s microscopy products. Now, with Marc Beuken on board as an exclusive consultant, who brings with him a lifetime’s experience in the sector, we are poised to take undisputed leadership in both high- and low-volume additives and modifiers for optimal bitumen production to meet all industrial applications.”

![This image is a superimposition of all three channels (three light wavelengths): Grey is the reflected light bright field image of the sample surface (white light, approx. 450-700 nm wavelength). Since a black-and-white camera is used, the image is only grey. However, the bitumen inclusions are clearly visible as bright spheres surrounded by fluorescent aggregate in a homogeneous manner. This is therefore the ideal distribution.The green-blue colour of the aggregate results from the superimposition of two-colour images. The first colour image shows the green fluorescence (FITC fluorescence filter: excitation light approx. 475 nm [blue], emitted light approx. 520 nm [green]), the second colour image shows the blue fluorescence (AQUA fluorescence filter: blue-violet excitation light, approx. 420 nm, emitted light approx. 465 nm [blue]). Magnification 100x.](https://industry.nikon.com/en-gb/wp-content/uploads/sites/6/2025/10/Overlay-BrightfieldFITCAQUA.jpg)