In November, motorists across many Northern Hemisphere regions experience increased fog that can severely reduce road visibility. The combination of shorter days, cooler temperatures, and changeable weather creates ideal fog conditions.

When driving in fog, it’s appropriate to use fog lamps. These are positioned low on the vehicle and cast a wide beam, helping to illuminate the road immediately ahead whilst minimising glare and enhancing visibility.

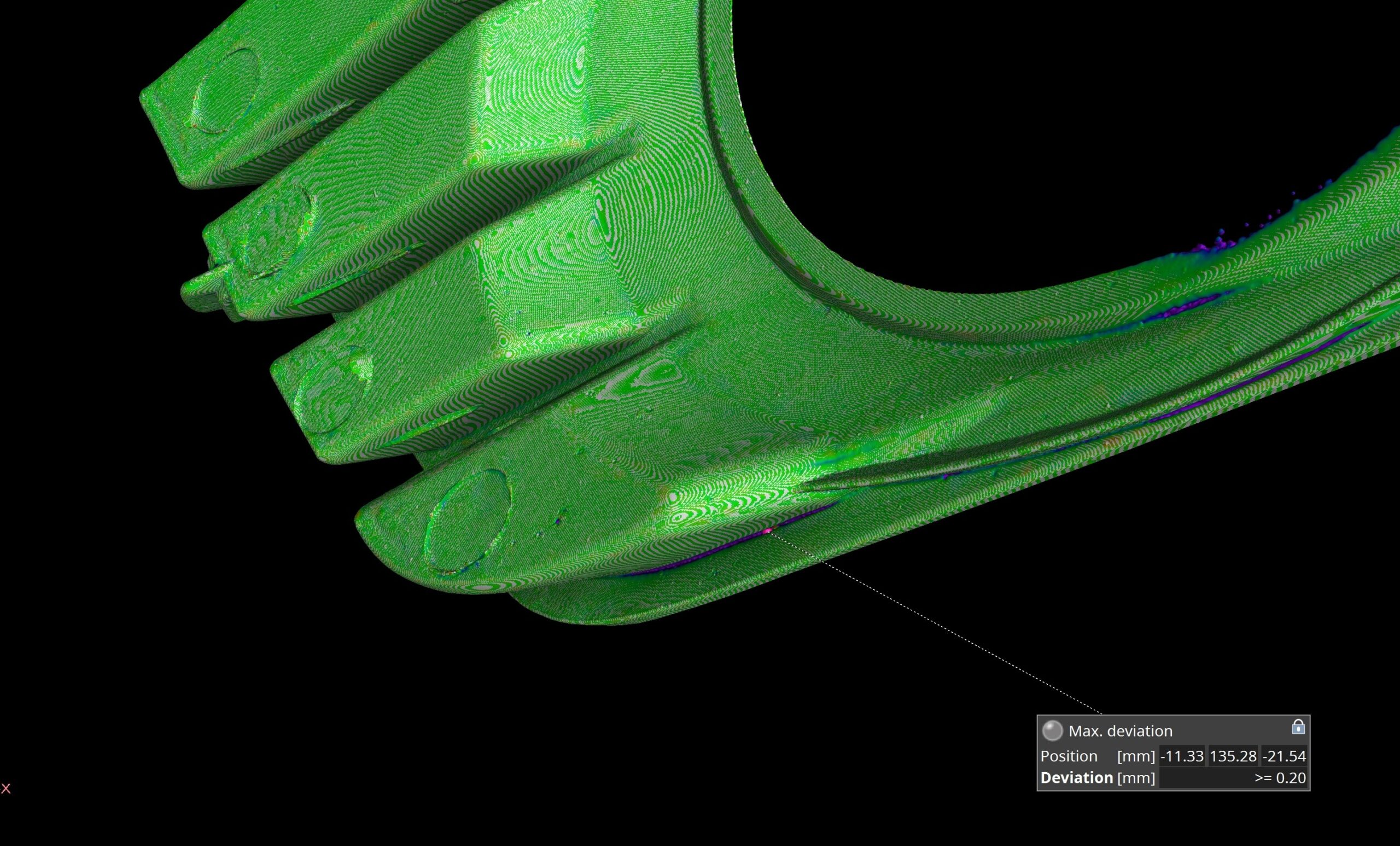

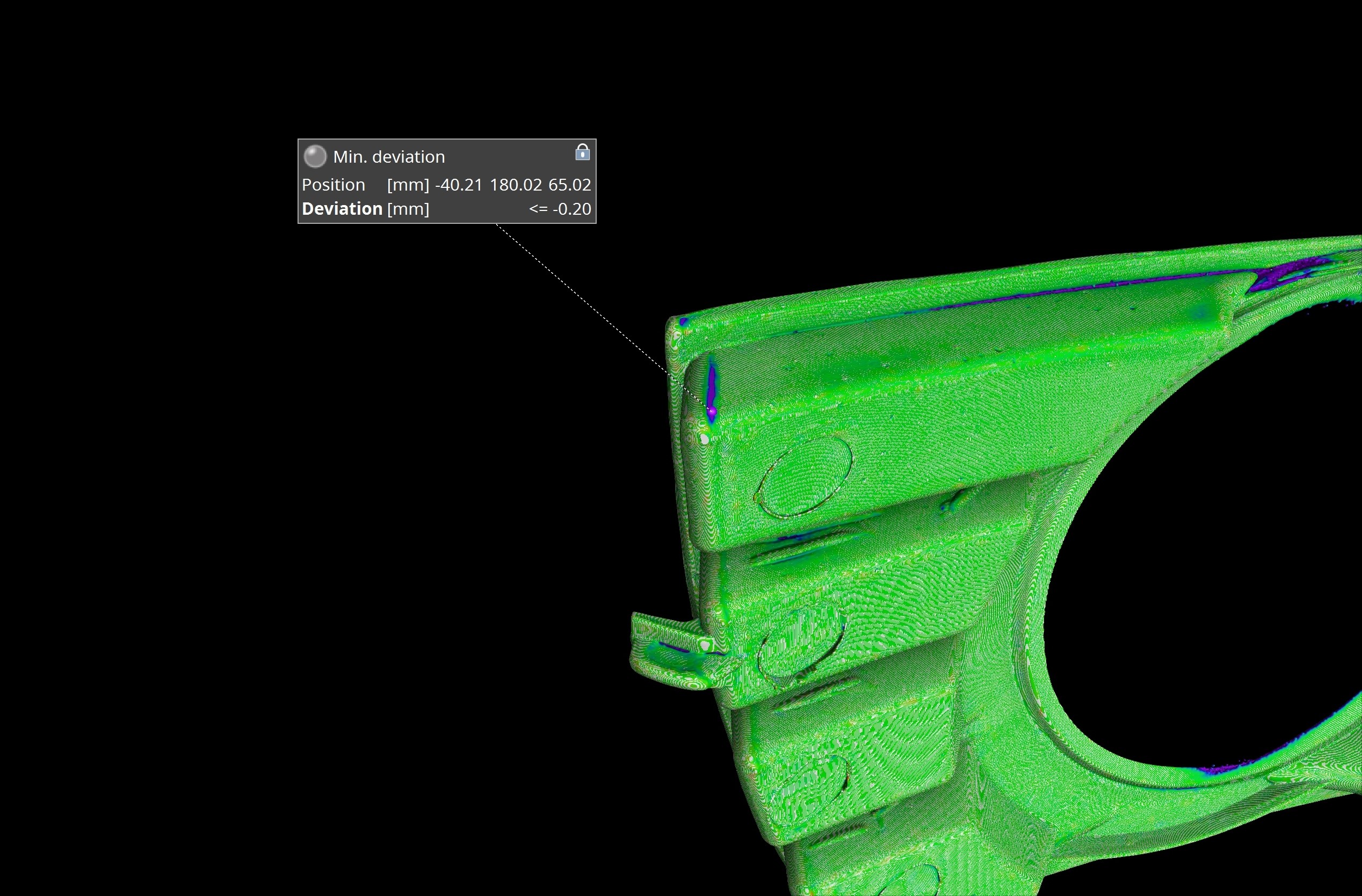

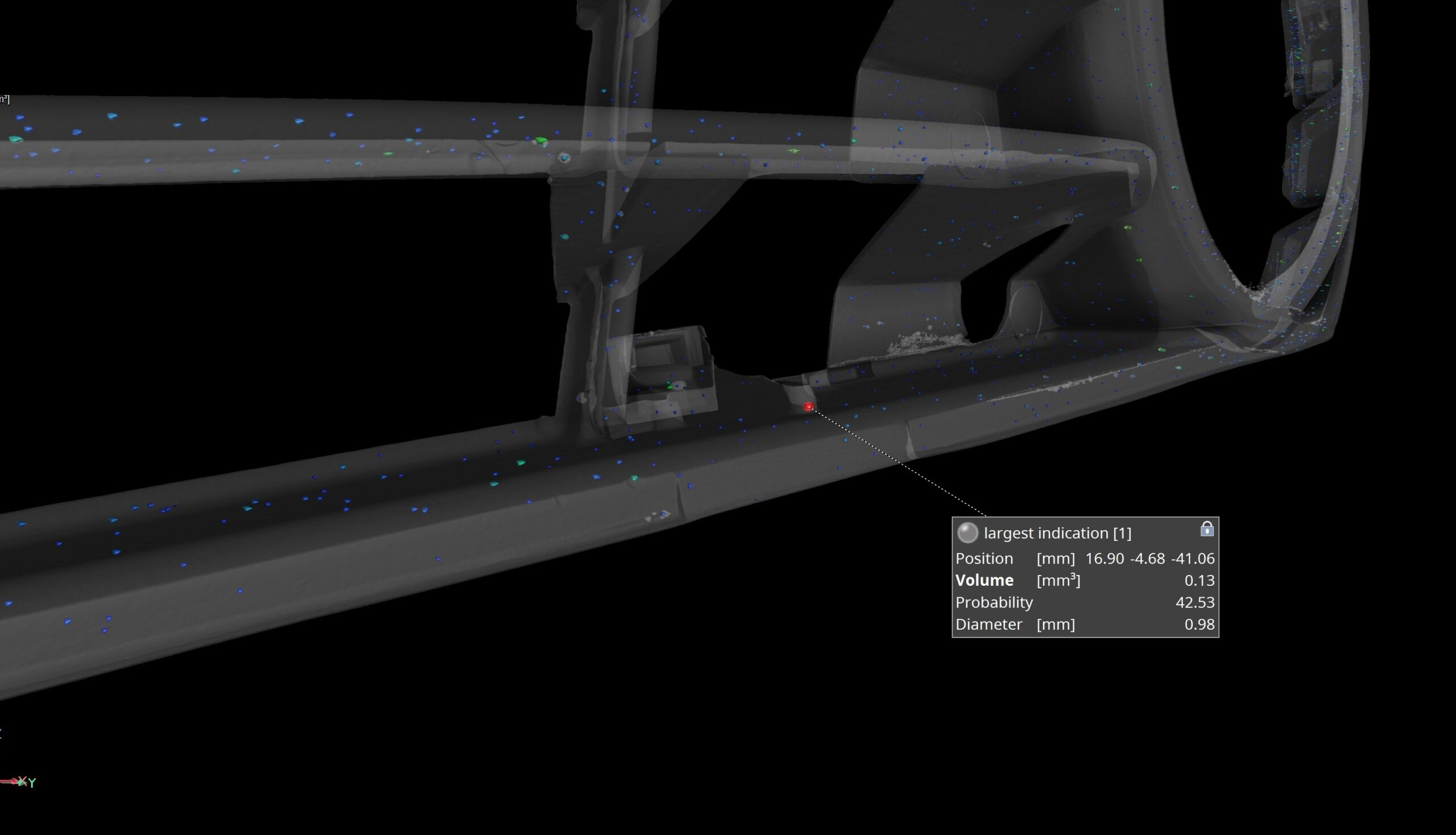

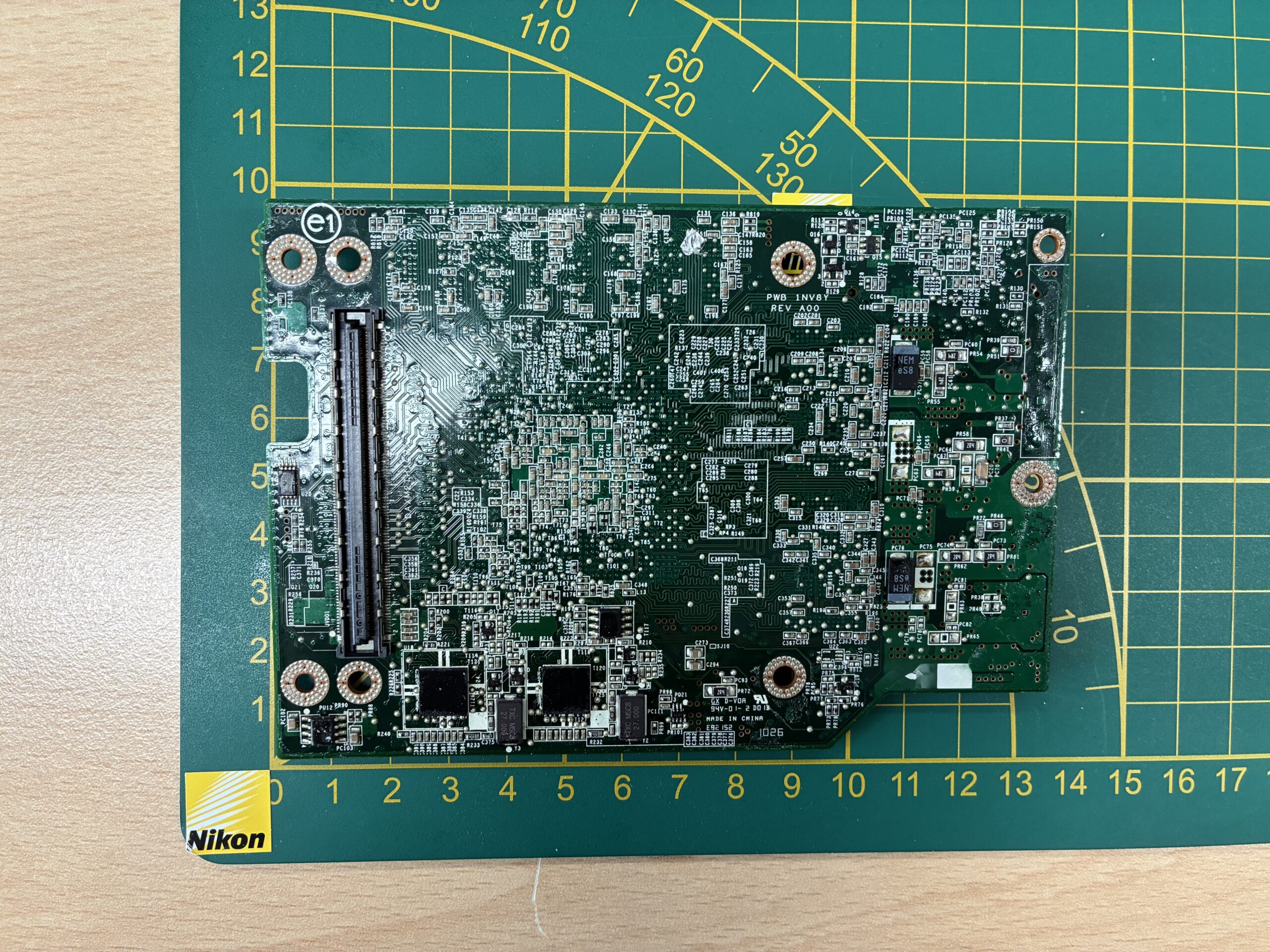

So for November’s Scan of the Month at Nikon, Samir Kadi, Application Engineer X-ray & CT, has scanned a plastic fog light. Let’s discover the several practical reasons why plastic is used for automotive fog lights:

- Durability: plastic materials used for fog lights, like polycarbonate, are highly durable and impact-resistant compared to glass. This durability helps prevent damage from road debris, rocks, and other hazards.

- Weight reduction: plastic is significantly lighter than glass. Using plastic for fog lights helps reduce the overall weight of the vehicle, helping to improve fuel efficiency and handling.

- Cost-Effectiveness: plastic components are generally cheaper to manufacture and replace than glass. This makes it more cost-effective for both manufacturers and consumers.

- Design Flexibility: plastic can be easily moulded into various shapes and designs, allowing for more creativity in the design of fog lights. This flexibility enables manufacturers to improve the aesthetics and functionality of the lights.

- Safety: in the event of a collision, plastic fog lights are less likely to shatter into sharp pieces than glass, reducing the risk of injury to vehicle occupants and pedestrians.

- UV and Weather Resistance: modern plastic materials are often treated to resist UV radiation and other environmental factors, ensuring the fog lights remain clear and functional over time without yellowing or becoming brittle.

If you want to know more about the several components present inside the fog light assembly, read our Scan of the Month for March.

These X-ray CT scans were acquired using Nikon’s Offset CT acquisition algorithm at an X-ray power of 80 W and voxel resolution of 84 µm, using a Nikon X TH 225 ST 2x. This system comes equipped with up to three different Nikon microfocus X-ray sources: a 180 kV, 20 W transmission target, a 225 kV, 225 W reflection target and a 225 kV, 450 W Rotating.Target 2.0.

The scan was performed using the 225 kV Rotating.Target 2.0 coupled with a Varex XRD 4343CT flat panel detector. The detector acquired 8,152 projections (4 frames/projection) (individual radiographs) at an exposure time of 500 ms and a gain of 6 dB, resulting in a total scan time of four hours and 30 minutes. This detailed work required a scan longer than more typical X-ray CT scans performed by Nikon technology, which can be as low as 1 minute with a configurable number of projections.