Even though the days are getting longer and the weather is generally milder in March, fog and mist can still reduce visibility, especially during the early morning or late evening hours. This month, Onur Cildir, Application Engineer X-ray & CT, has scanned a fog light to highlight its essential role in safe driving.

Fog lights were originally developed for military vehicles during World War II. The Royal Air Force (RAF) used them on aircraft and vehicles to navigate through foggy conditions during missions. After the war, the technology was adapted for civilian vehicles, becoming a standard safety feature to enhance visibility during adverse weather conditions.

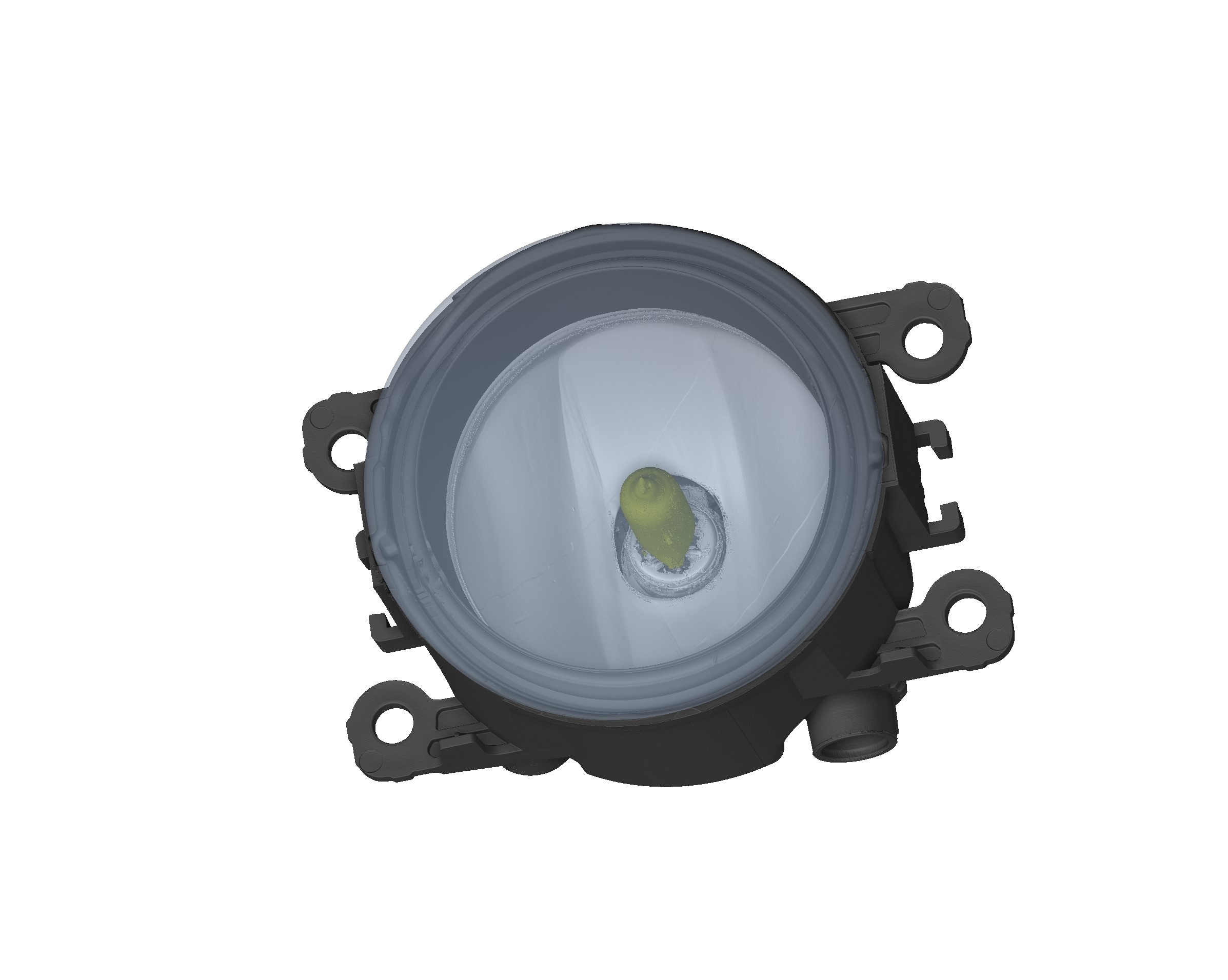

The design of fog lights typically involves a wide, shallow reflector that spreads the light output horizontally and downward. Fog lights are usually positioned low on the front bumper of the vehicle, below the level of headlights. This placement helps to illuminate the road surface directly in front of the vehicle, making it easier for the driver to see obstacles, other vehicles or pedestrians in low-lying fog or mist. Unlike headlights, which can reflect off particles in the air during foggy conditions, fog lights are positioned lower on the vehicle, reducing the glare and reflection that can impair visibility.

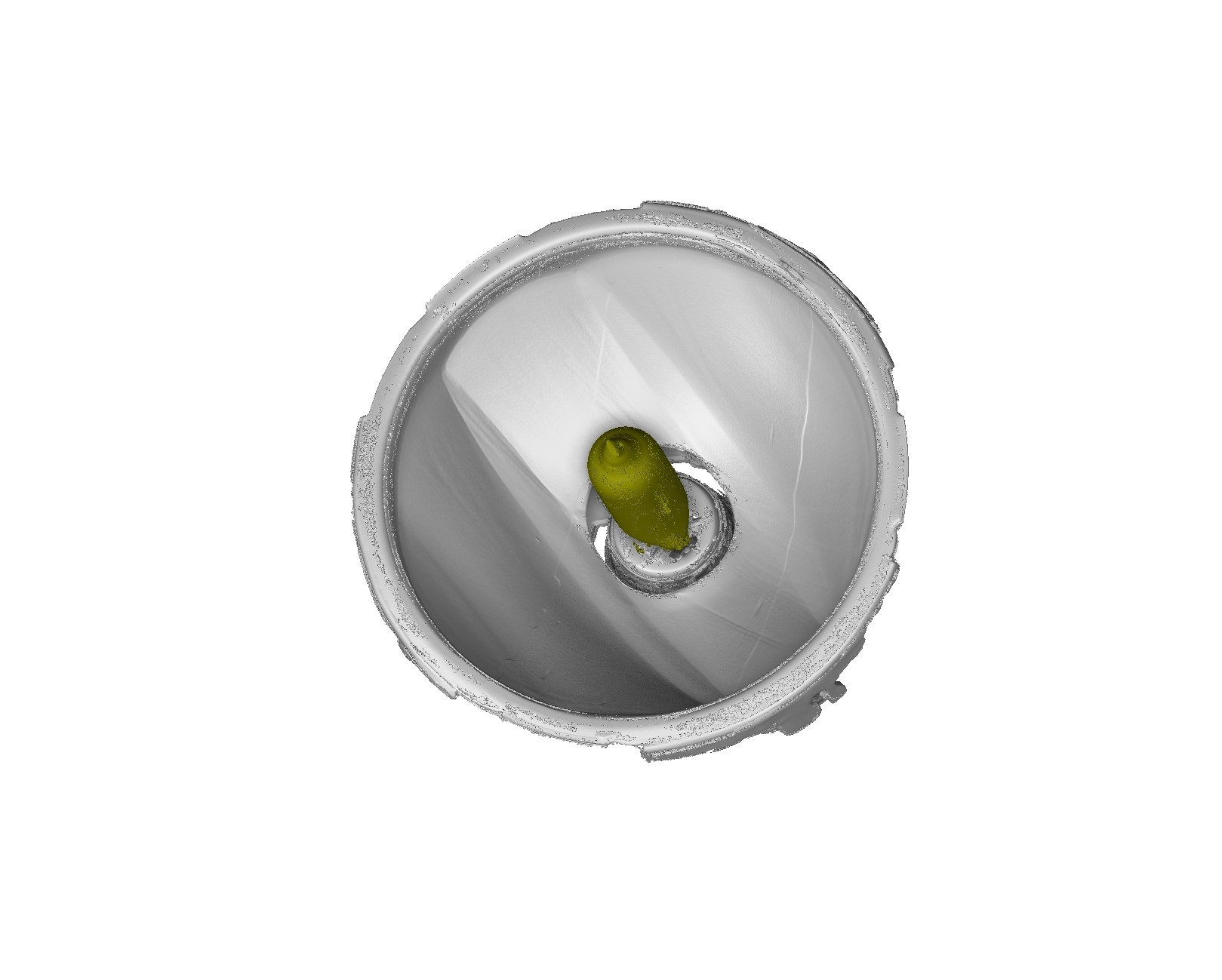

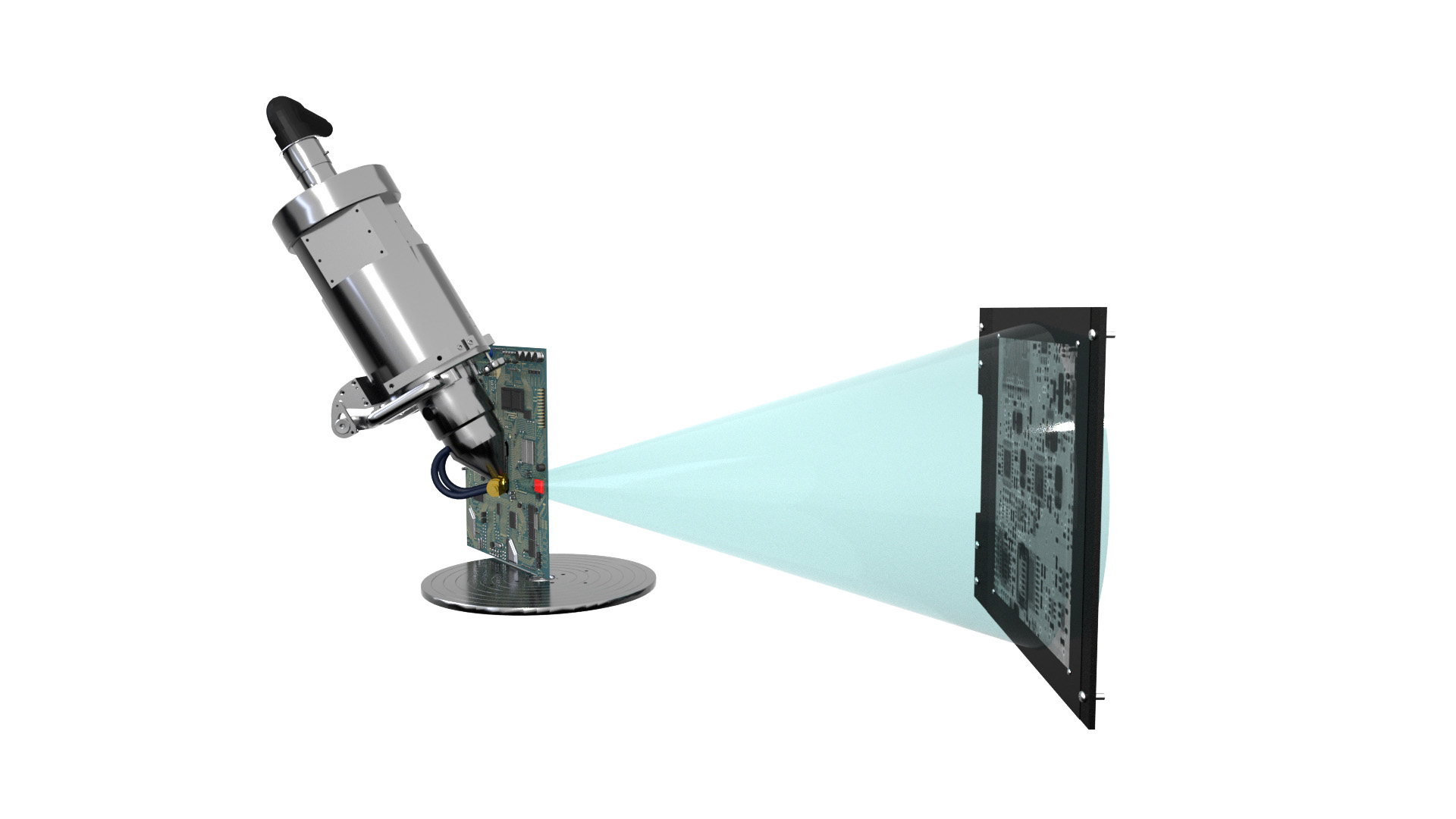

These X-ray CT scans were acquired using Nikon’s circular CT acquisition algorithm at an X-ray power of 145 W and voxel resolution of 50 µm, using a Nikon XTH 225 ST 2x. This system comes equipped with up to three different Nikon microfocus X-ray sources: a 180 kV, 20 W transmission target, a 225 kV, 225 W reflection target and a 225 kV, 450 W Rotating.Target 2.0. This scan was performed using the 225 kV Rotating.Target 2.0 coupled with a Varex XRD 4343CT flat panel detector. For this scan, the detector acquired 4476 projections (4 frames/projection) (individual radiographs) at an exposure time of 250 ms and a gain of 24 dB, resulting in a total scan time of 1 hours and 15 minutes.

Thanks to these scans, we can observe the several components present inside the fog light assembly:

- Bulb: the light source, which can be a halogen, LED or HID bulb, depending on the make and model of the vehicle. This bulb emits the light that illuminated the road ahead.

- Reflector: a reflective surface behind the bulb that helps direct and focus the light output in a specific direction. The reflector is designed to distribute the light evenly and create the desired beam pattern.

- Lens: a transparent cover that protects the bulb and reflector from damage and weather elements. The lens also helps to diffuse the light and ensures it spreads out evenly.

- Housing: the outer casing of the fog light assembly, which provides structural support and houses all the internal components.

- Wiring and connectors: electrical wiring and connectors that connect the fog light to the vehicles’ electrical system. These components allow the fog light to be turned on and off using the vehicles’ controls.