March 4th has been proclaimed as the World Engineering Day for Sustainable Development by UNESCO in order to raise awareness on the role of engineering for a more resilient world. For this Scan of the month, we would like to celebrate this important date and how our X-ray CT systems can contribute to an advanced sustainable development in different industries.

Did you know that cement production accounts for almost 10% of global CO2 emissions? Engineers are constantly looking for innovative ways to strengthen the built environment and reduce the environmental impact of construction projects. Recently, green concrete appears as an eco-friendly material that can revolutionise the building industry.

Green concrete is concrete in which all or part of the mineral aggregates are replaced by vegetal aggregates. This substitution modifies its performance and from the point of view of the physical characteristics green concrete is an excellent thermal and sound insulator. It benefits from a low density and a high plasticity due to the porosity of the aggregates. Indeed, green concrete offers a great diversity of composition and technical characteristics. This allows them to adapt to various requirements and uses.

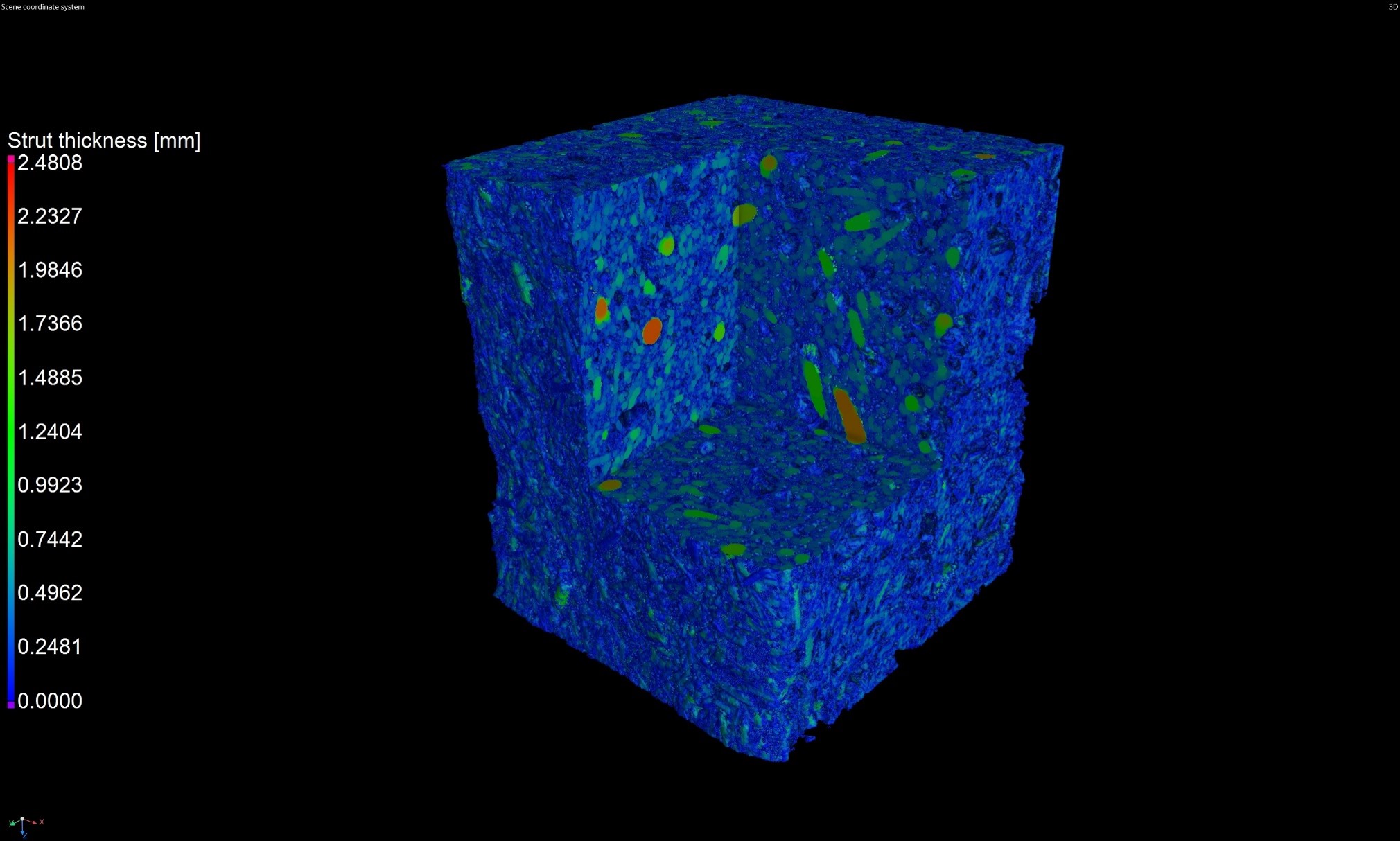

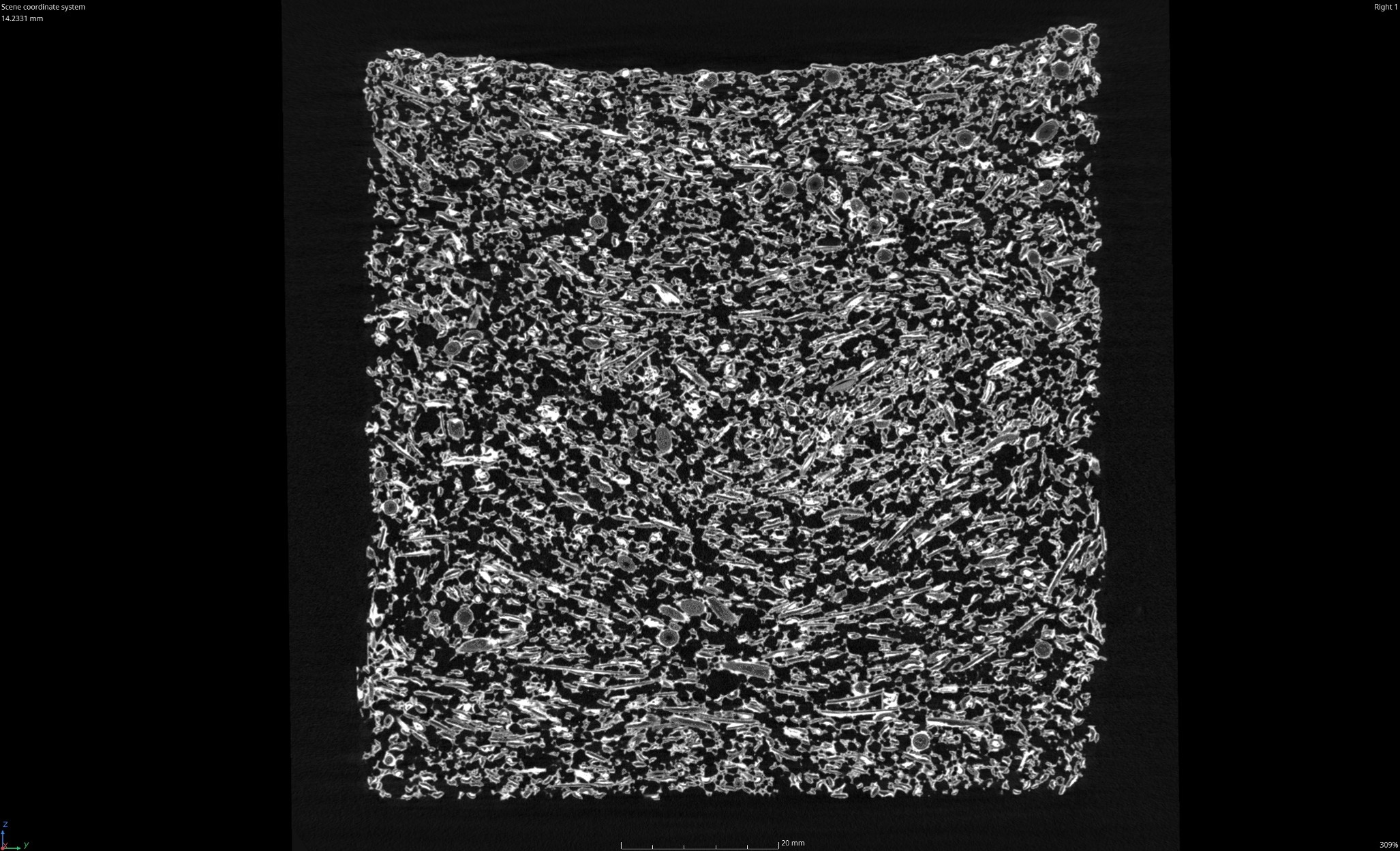

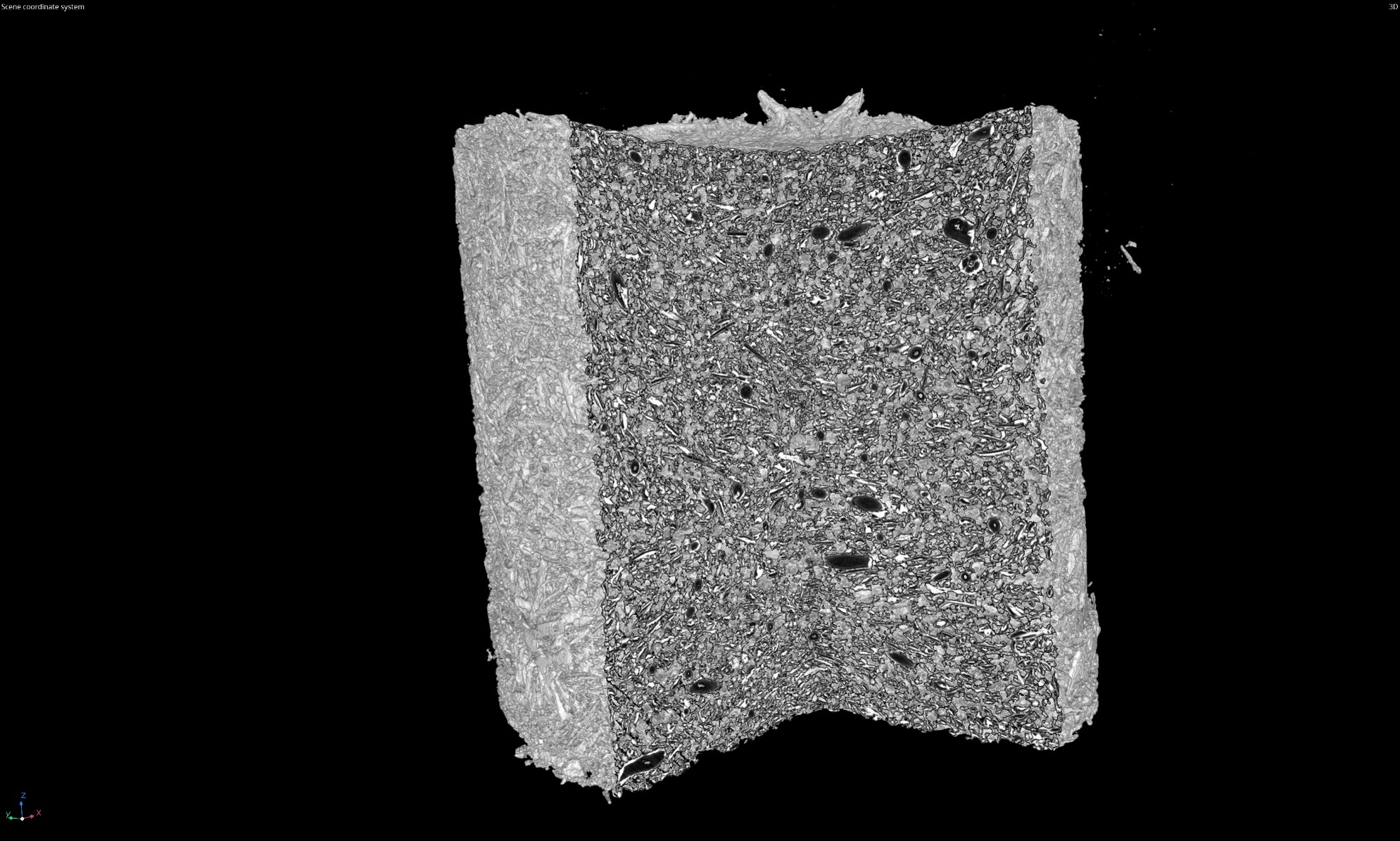

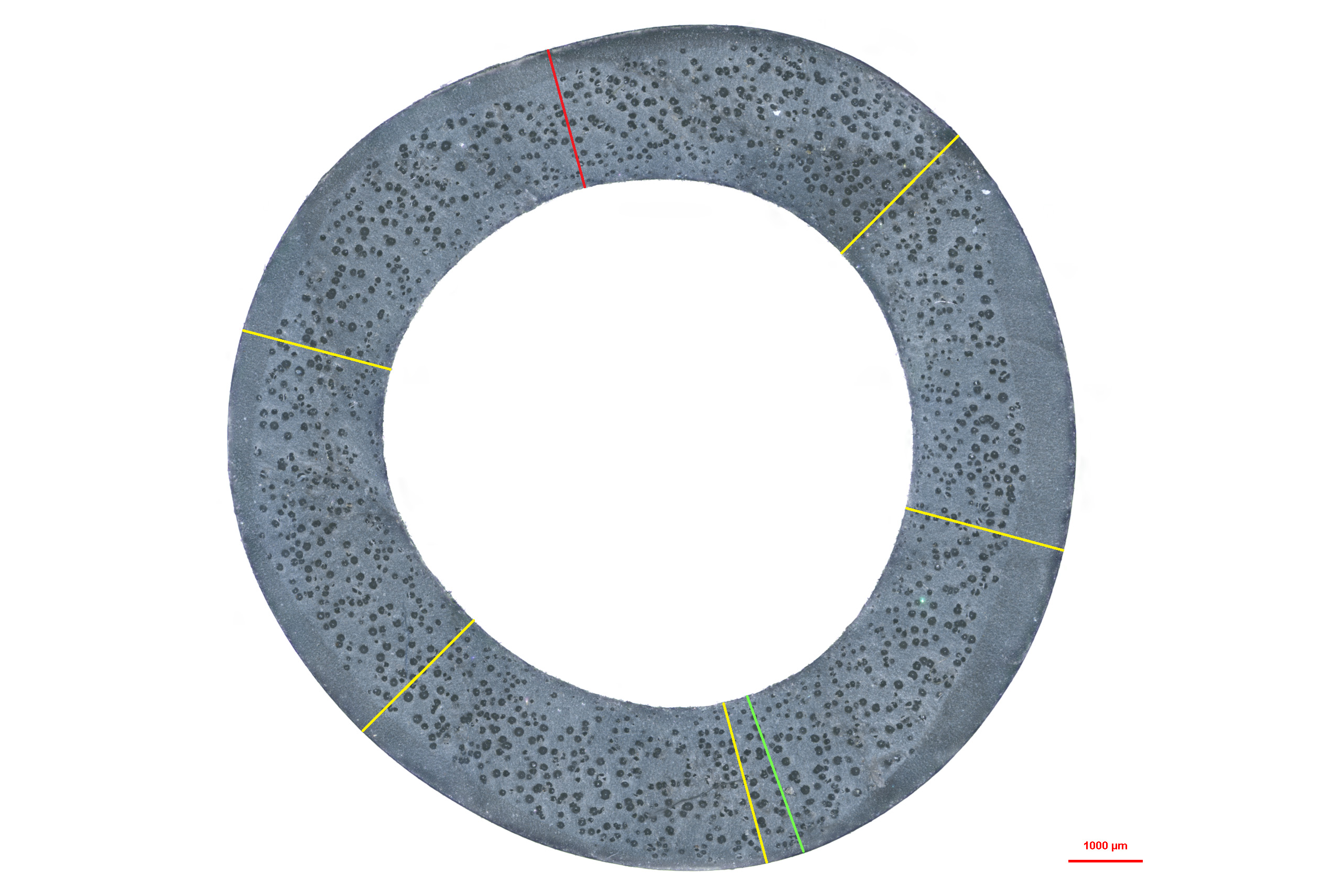

The analysis of the internal structure of green concrete is important both academically, for geological and earth sciences, and industrially, for the construction sector. That is why the Université d’Artois (located in France) has used a XT H 225 ST 2x system to analyse different green concrete parts. X-ray CT is perfectly adapted for this analysis as it helps to visualise the quantity and sizes of the pores, to determine the capillary porosity (open and/or closed), and to observe the proportions and orientation of the vegetal aggregates.

The X-ray CT scans were acquired using Nikon’s helical acquisition algorithm (X.Tend) at a combined X-ray power between 15 and 60 Watts and a voxel resolutions between 23 and 55µm, using a Nikon XT H 225 ST 2x. This system comes equipped with up to three different Nikon microfocus X-ray sources: a 180 kV, 20 W transmission target, a 225 kV, 225 W reflection target and a 225 kV, 225 W Rotating.Target 2.0. The scans were performed using the 225 kV reflection target coupled with a Varex XRD 4343CT flat panel detector. For these scans the detector acquired between 4476 and 9190 projections (individual radiographs) at an exposure time between 125 and 354ms, resulting in a total scan time between 20 and 55 minutes.