Products and promotions may differ based on your selected region.

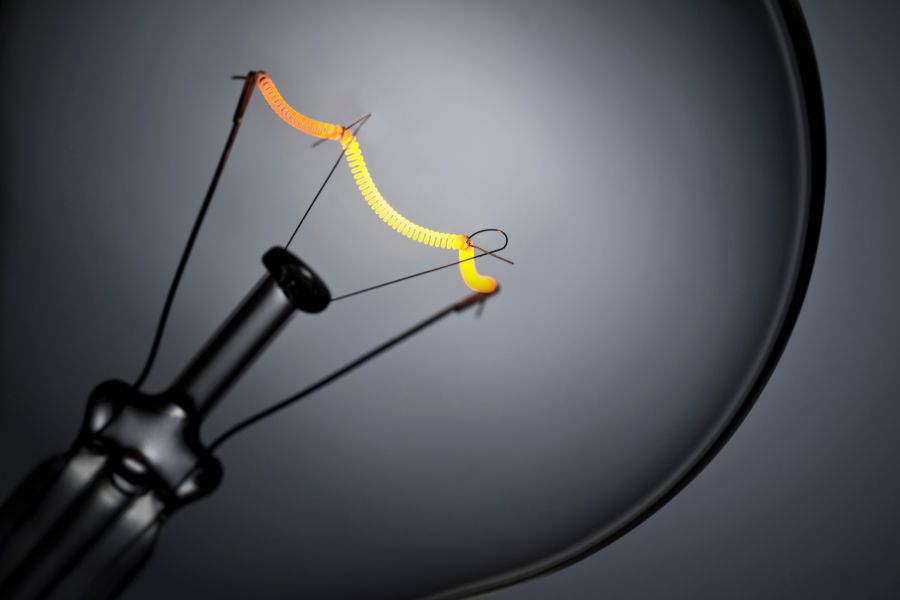

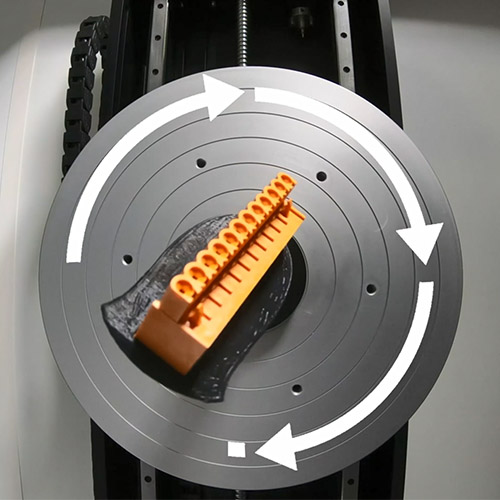

In a production environment, it is not enough just to automate user operations. Advanced technology also plays an important role. High-flux X-ray sources like the Nikon Rotating.Target 2.0 and dedicated CT scanning strategies like Half.Turn CT significantly cut scans times, while Auto.Filament Control doubles filament lifetime, improving system up-time.

As standard, CT profiles containing all acquisition and analysis parameters can be stored and recalled later. This allows the whole process to be automated without the need for any programming skills, ensuring repeatable, operator-independent results.

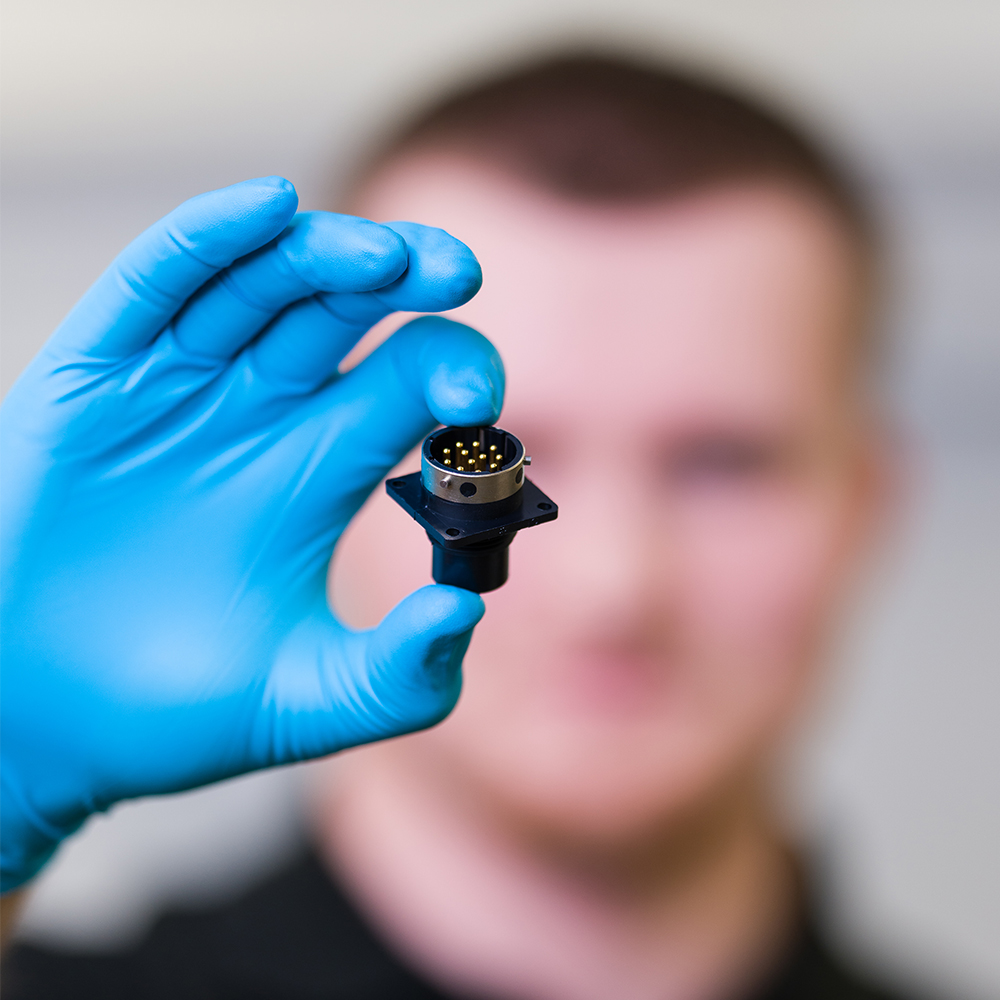

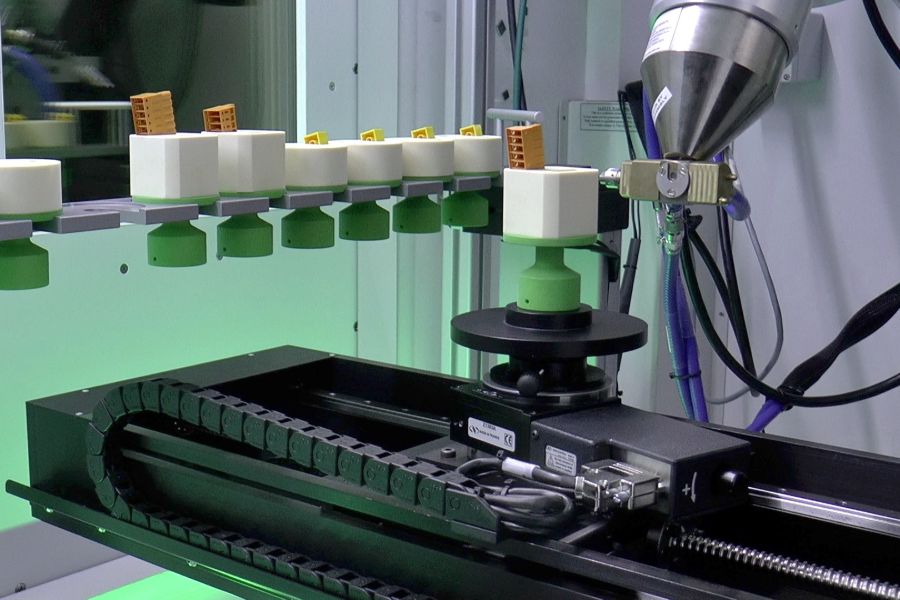

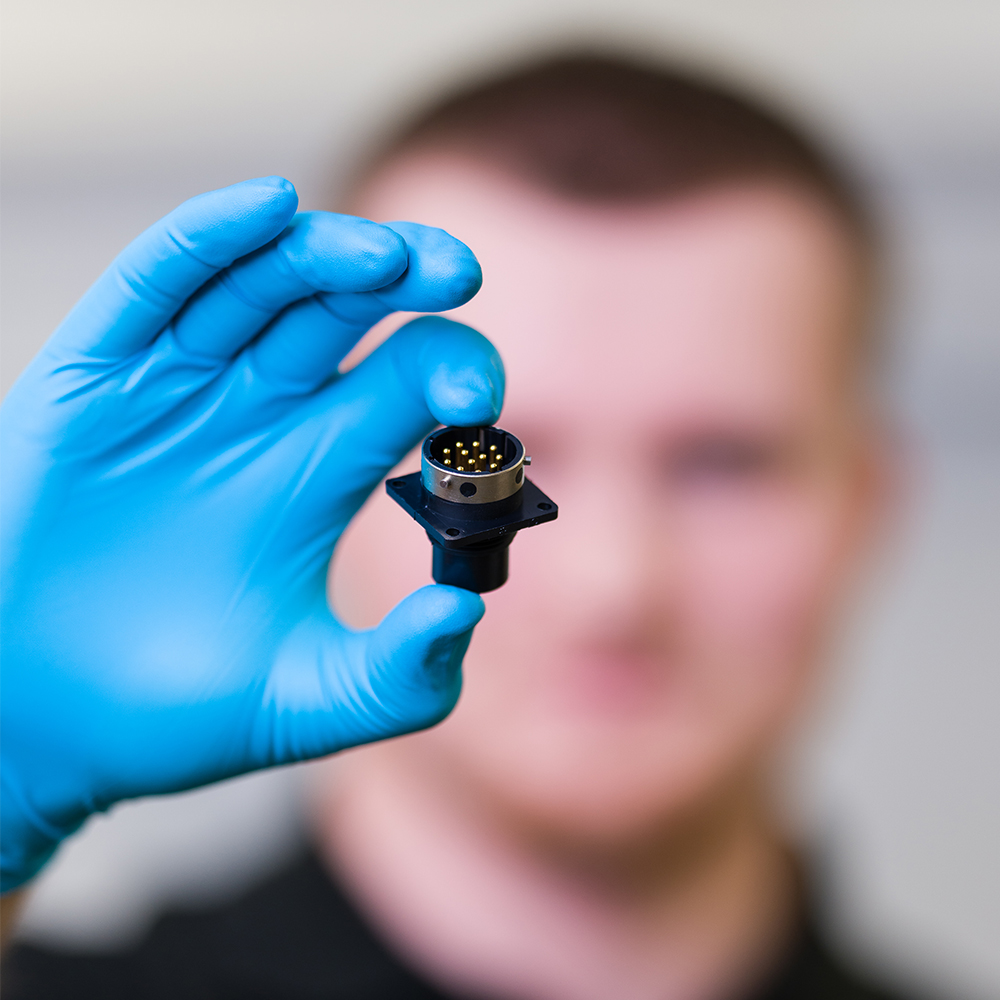

With Autoloader, putting a series of sample holders in the machine is the only manual operation. Part loading and identification, program selection, data acquisition, analysis and reporting are completely automated.

Robotic sample loading enables fully automated, unattended CT inspection in a production environment with industry-standard communication interface OPC UA. By looping this information back to the Manufacturing Execution System, production processes can be controlled and optimised in real-time

If you would like further details on this product or a more in-depth description, our expert team will provide you with additional information and, if required, arrange an on-site visit.

Talk to us in detail about your project and our experts will advise you on the best inspection system to meet your requirements.

Please fill out the form opposite and we will get in touch with you shortly.