Nikon’s advanced microscopy technology has brought new levels of precision to Gruppe Matzdorf’s diamond tool production. The German company, facing quality control hurdles, has adopted Nikon’s LV100ND microscope as a pivotal solution.

Nikon Industrial Metrology and Gruppe Matzdorf GmbH have announced the successful integration of Nikon’s LV100ND light microscope with Differential Interference Contrast (DIC) technology into Matzdorf’s quality control processes for ultra-precise diamond tools.

This innovative combination enables seamless inspection of tool edges, unlocking a new era of manufacturing efficiency and quality assurance in the micro tool industry.

Nuremberg-based Matzdorf faced a significant challenge in quality control. The company struggled to effectively detect microscopic chips or defects on the cutting edges of its critically important precision tools. Even tiny imperfections could significantly impact tool performance and compromise the quality of final products manufactured using these tools. Finding a solution that enabled precise and efficient inspection of these micro tools was crucial for Matzdorf to maintain its high-quality standards and reputation in the industry.

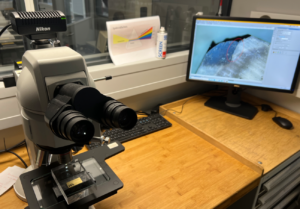

In January 2024, Gruppe Matzdorf GmbH upgraded its quality control processes with advanced Nikon equipment. The company invested in a Nikon LV100ND light microscope featuring a high-resolution DS Fi3 camera and NIS (Nikon Imaging Software) for sophisticated image analysis.

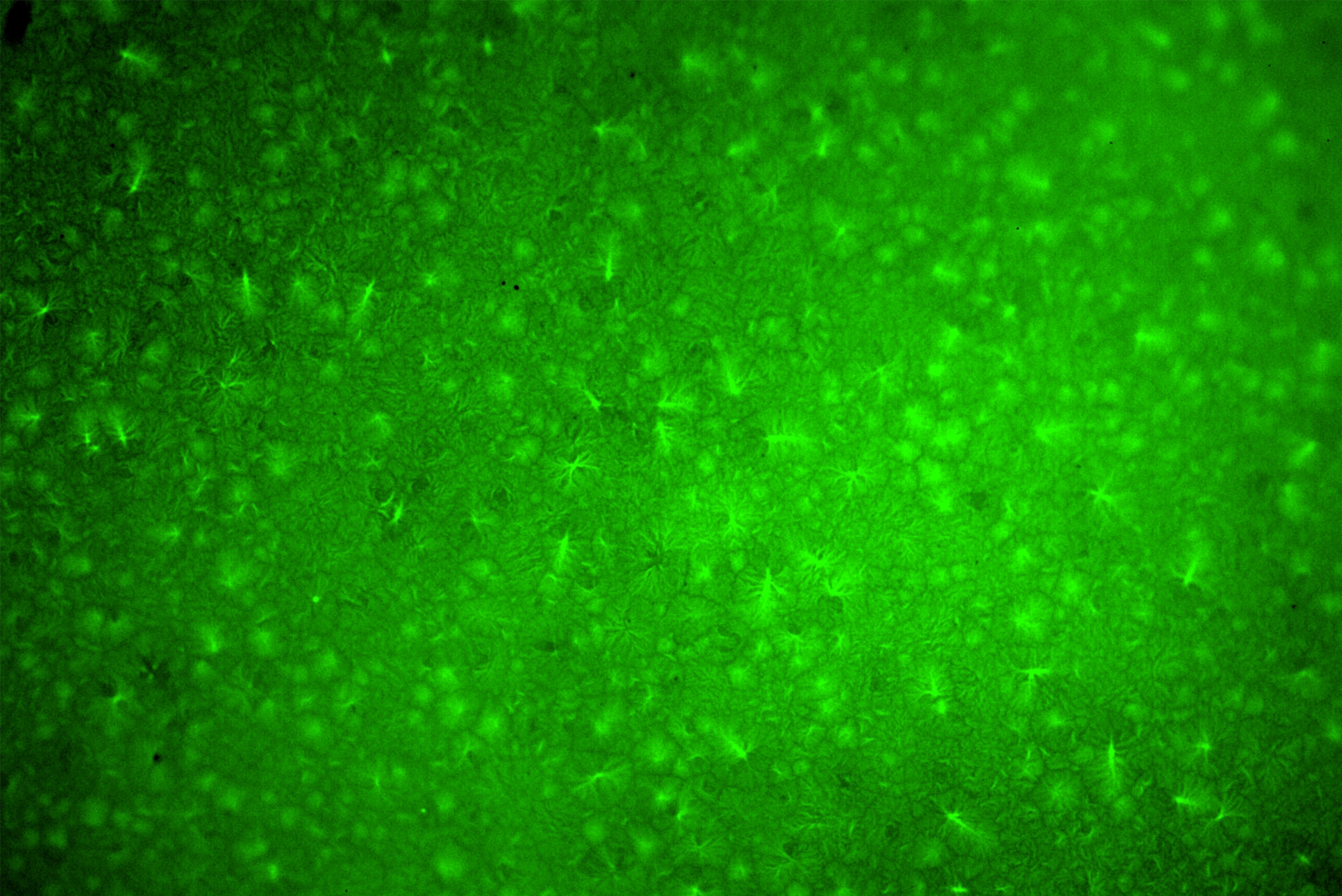

A key feature of this setup was the implementation of Nikon’s Differential Interference Contrast (DIC) technology. This advanced microscopy technique significantly enhances contrast and detail detection, particularly effective for transparent or low-contrast samples, which works by splitting polarised light into two beams.

As these beams pass through the sample, they undergo different phase shifts based on variations in the sample’s thickness and refractive properties. When recombined, these phase differences create an interference pattern. The microscope’s specialised optics translate this pattern into a high-contrast image, revealing fine structures and surface details with exceptional clarity.

This process allows for precise and detailed visualisation of the tool edges, making detecting even the smallest imperfections or chips possible. Nikon has streamlined this sophisticated technique into a simple slider that fits into the microscope’s nosepiece. This ingenious design allows the DIC process to be applied across all magnification levels using a single slider, significantly simplifying and expediting the inspection process.

The system’s high-resolution microlenses, offering 150x magnification and infinite correction, proved invaluable in the inspection process. These lenses balance high numerical aperture and resolution while providing sufficient working distance beneath the sample. This combination enhances both the quality and ease of the inspection process.

Gerhard März, who leads production at Matzdorf, thoroughly evaluated the Nikon equipment’s implementation. März and his team expressed great enthusiasm for the positive effects the Nikon system has had on their daily operations. They noted significant improvements in their product quality, inspection processes, and documentation capabilities.

“The Nikon microscope with accessories helps us to improve and continue to ensure our quality in the company every day,” says März.

The LV100ND light microscope, equipped with DIC technology and high-resolution microlenses, enabled Matzdorf’s staff to identify edge chipping on their tools with remarkable clarity and accuracy. This capability led to substantial enhancements in both quality control processes and final product quality.

Furthermore, the DS Fi3 high-resolution camera and NIS image analysis software significantly improved documentation capabilities. These tools allowed the team to capture detailed inspection images and perform in-depth analyses, which proved valuable for internal record-keeping and communicating product quality to customers and suppliers.

The adoption of Nikon equipment profoundly impacted Matzdorf’s quality control operations. The enhanced ability to accurately identify chipping on diamond micro tool edges allowed the company to elevate its product quality, reinforcing its status as a premier supplier of ultra-precision tools. This investment in Nikon technology proved a strategic move, bolstering Gruppe Matzdorf GmbH’s competitive edge and industry standing.

Matzdorf had been grappling with the issue of effectively identifying and managing edge chipping on their diamond micro tools. Implementing Nikon technology, specifically the LV100ND light microscope featuring cutting-edge DIC technology and high-resolution microlenses, marked a transformative development for the company. This advanced inspection capability empowered Matzdorf to elevate its quality benchmarks and solidify its market position in the ultra-precise diamond tool sector.