December is a month filled with discovery and joyful surprises. As children unwrap new toys and explore the technology hidden within them, Nikon Metrology takes the opportunity to do the same, with the help of X-ray CT. For this festive edition of Scan of the Month, Thomas Dreisbusch, X-ray Application Engineer, has scanned the tiptoi® interactive learning toy, a familiar device that blends optics, audio and compact electronics into a child-friendly handheld format.

Using Nikon’s advanced X-ray CT solutions for this month’s scan showcases how CT can reveal the engineering behind everyday consumer products.

What’s inside a tiptoi®?

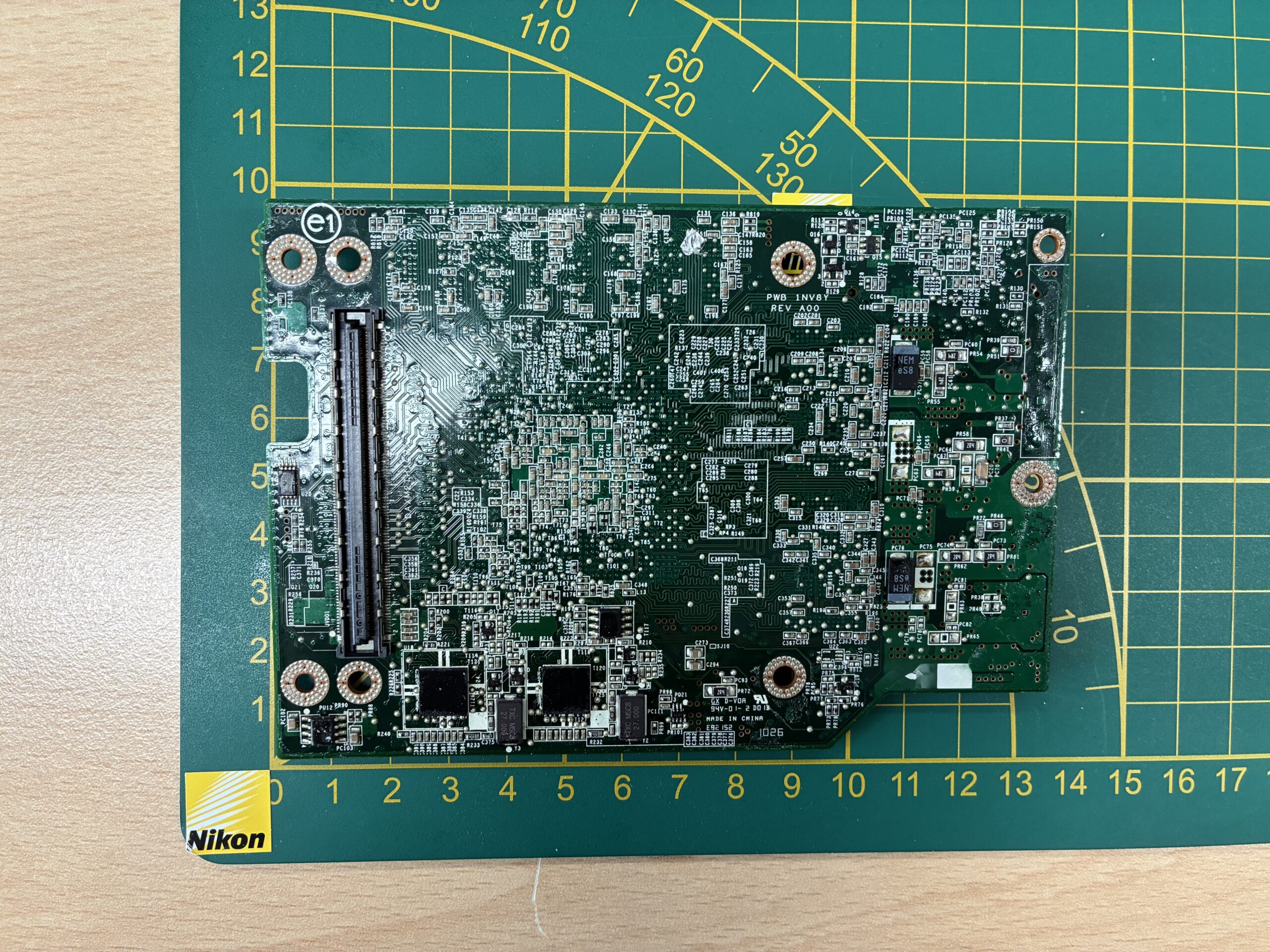

The tiptoi® operates as an interactive audio pen. A small optical sensor reads microdot patterns on specially printed surfaces, a microcontroller interprets those codes, and onboard memory stores the corresponding audio content. A miniature loudspeaker delivers the sound output, while the batteries and power electronics ensure stable operation.

All these components are arranged in compact, impact-resistant polymer housing designed for everyday use by children. X-ray CT is the ideal tool for assessing how these pieces fit and function, as it provides a nondestructive method capable of visualising fine electronic details.

Scanning details

The tiptoi® was scanned using the Nikon XT H 225 ST 2x, equipped with the 225 kV Rotating Reflection Target. A helical CT technique was chosen to ensure a smooth and consistent voxel size across the full length of the device. The scan was performed at 185 kV and 78 W, producing a voxel resolution of 27 μm. The data was captured on a Varex XRD 4343CT flat panel detector with an 18 dB gain and an exposure time of 354 ms per frame. The detector acquired 7 619 projections (4 frames/projection) resulting in a total scan time of 3 hours, which is much longer than the normal CT scan of 1-5 minutes, because of the extremely high resolution and complex material.

Watch the video below which reveals the internal architecture: https://youtu.be/vVtcQ98Az8c

The reconstructed CT volume reveals the tiptoi® multilayer printed circuit board, its microcontroller and memory devices and the alignment of the optical sensor within the tip. The miniature speaker and magnetic components appear with high clarity, and internal ribbing within the plastic shell shows how durability is achieved without adding unnecessary weight.

Because CT allows digital slicing at any angle, engineers can examine internal solder joints, verify component placement and evaluate assembly quality without opening or damaging the toy.

CT for safer and more reliable electronics

With millions of electronic toys exchanged during the holidays, ensuring their quality and safety is essential. Nikon X-ray CT technology enables manufacturers to identify hidden defects, measure internal structures and compare assemblies against CAD data.

Whether used in research and development or in production environments, Nikon systems such as the XT H Series, the XT V Series and the VOXLS Series provide fast, accurate and non-destructive insight that supports consistent product quality and greater consumer confidence.

As families unwrap new toys this month, Nikon Metrology teams are pleased to share a glimpse of the technology that helps make these moments both magical and safe.