Nikon’s work with NM3D Ibérica is transforming metrology in Portugal and Spain. As the official sales agent, NM3D leverages Nikon’s X-ray CT technology to offer world-class quality control solutions across industries, from automotive to aerospace, securing its position at the forefront of Iberian manufacturing innovation.

Nikon’s X-ray computed tomography (CT) technology has empowered NM3D Ibérica to revolutionise quality control and inspection processes across the Iberian peninsula. This relationship has helped position NM3D — Nikon’s official sales agent in Portugal and Spain — as a key player in providing industry-leading metrology solutions for a diverse clientele spanning manufacturers, educational institutions, and museums.

Established in 2016, NM3D Ibérica leverages Nikon’s advanced X-ray CT systems to tackle complex inspection challenges in various industries, from automotive to aerospace. The company’s network of strategically located laboratories and offices across Portugal and Spain — including its headquarters in Vila Nova de Cerveira, northern Portugal, Oliveira de Azeméis and Marinha Grande, and the Spanish cities of Madrid, Barcelona, Vitória and Vigo — enables them to offer both direct sales of metrology equipment and subcontract inspection services, with a significant portion of their business revolving around Nikon’s X-ray CT technology.

NM3D’s adoption of Nikon’s state-of-the-art CT scanning systems has not only enhanced their ability to perform high-resolution examinations of internal structures in dense materials but also opened new avenues for reverse engineering and additive manufacturing support.

NM3D’s primary business, accounting for 80 per cent of its revenue, is the sale of metrology systems. The company caters to a diverse clientele, including manufacturers, educational institutions, and museums. A significant portion of these sales involves Nikon’s X-ray CT systems.

In addition to direct sales, NM3D Ibérica provides subcontract metrology services. Utilising Nikon’s advanced X-ray CT technology, the company performs inspections for clients. This cost-effective option enables manufacturers to benefit from X-ray CT technology without the substantial initial investment of purchasing their own system. However, many clients eventually opt to acquire their own inspection equipment.

The wide range of industries served by NM3D underscores the versatility of X-ray CT technology. The company has successfully addressed inspection challenges for various products, from cork stoppers to complex semiconductors. This technology allows for high-resolution examination of internal structures in artefacts, even those composed of dense materials.

X-ray CT is also particularly suited for reverse engineering applications, enabling the creation of digital models without damaging the original sample. An unusual project undertaken by NM3D involved scanning a bamboo bassoon reed to develop a model for mass production.

Currently, the automotive sector represents the largest portion of NM3D’s business. However, this industry faces uncertainties regarding the timeline for phasing out internal combustion engines and the future dominance of battery or hydrogen-powered vehicles.

Consequently, Nuno Amaral, Area Sales Manager of NM3D, and his team are keen to diversify further into other industries they already serve, including aerospace, medical, and electrical and electronics sectors. Indeed, relay manufacturers and producers of connectors and cables already figure prominently in the firm’s customer base.

Additive manufacturing is another area supported, with X-ray CT proving a valuable tool for non-destructive inspection and measurement of 3D-printed components. An additional aspect of NM3D’s business is the provision of a subcontract additive manufacturing service.

A considerable boost to the company’s operations is now unfolding with the implementation of a European Commission economic package, NextGenerationEU, offering funding to help EU member states recover from the COVID-19 pandemic, particularly those that have been hit the hardest.

The project is worth €750 billion, of which €13 billion is earmarked for Portugal and five times that for Spain. NM3D hopes to boost sales to the educational sector, which is a prime target for the funding to promote high technology adoption by the next generation of engineers.

Nuno Amaral, who has been with the company since its foundation, considers one of NM3D’s unique selling points to be its customer-centric approach to sales, whereby bespoke metrology solutions are developed and sold to customers rather than simply packages of measuring equipment. Another USP is the elevated level of after-sales support, training and service that the company provides.

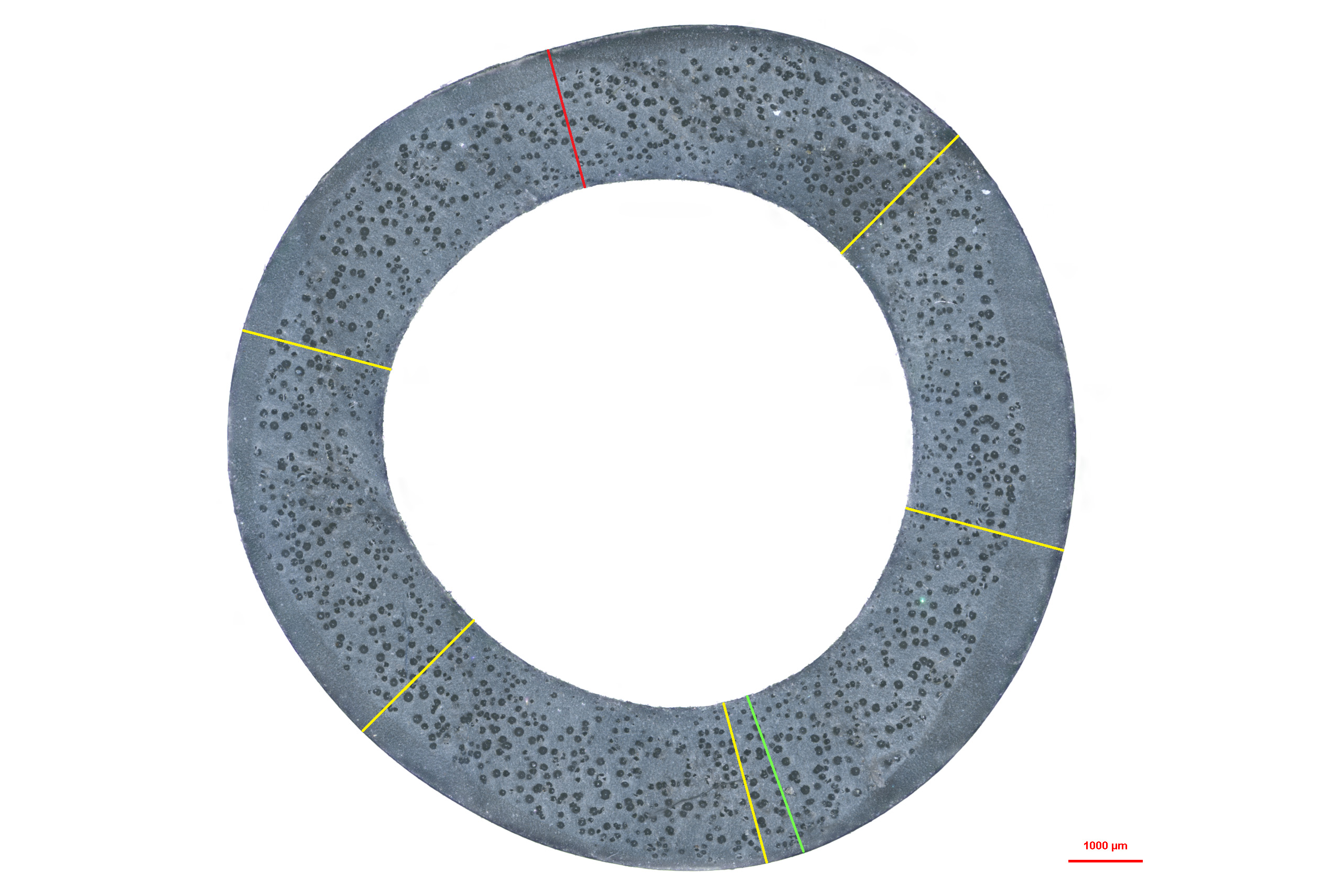

He cites one real-world example where the team in Vila Nova de Cerveira was able to help a customer improve its capacitor production by 3D CT scanning the product. The customer could visualise the capacitor’s interior for the first time, unlike the previous method of sectioning and destroying it.

The information obtained allowed the electrical component manufacturer to modify the manufacturing process, significantly improving the capacitor’s functioning. It was possible to anticipate the formation of internal air bubbles during production and adjust parameters in the line, thereby saving a substantial amount of scrap.

In another application, the connectors employed to feed power from the battery of an electric vehicle (EV) to its drive motors were CT scanned at either end to investigate the contacts and evaluate their propensity to loosen while the vehicle is being driven.

“Nikon’s proprietary X-ray sources play a crucial role in our ability to provide suitable solutions for the increasingly demanding challenges of our customers,” says Amaral. “The ability to identify internal defects such as porosities, cracks and inclusions is crucial to ensuring the safety and durability of products, especially in industries such as aerospace, automotive and medical.

“I particularly like the manufacturer’s X.Tend Helical data acquisition system, as it significantly improves the resolution and edge definition in most samples. It is especially useful when inspecting tall samples that are laminar in structure.

“We utilise it internally in our four microfocus Nikon CT scanning systems reserved for subcontract inspection, including in our large envelope machine for investigating big components, and I frequently recommend its use to our clients.”

He also singled out for praise Nikon’s Rotating.Target 2.0 in the XT H 225 ST 2x system that the bureau uses. Spinning the tungsten target efficiently dissipates the heat generated by the small focal spot size, enabling continuous generation of high-power X-rays and a dramatic increase in scanning speed and resolution. Other easily interchangeable Nikon targets are also in regular use, including a reflection target, a transmission target and a multi-metal target for material analysis.

On the subject of automation, Nuno Amaral sees potential in Iberia for the adoption of Nikon’s market-leading solutions for automated inspection, even in real-time within a customer’s production line, due to the high inspection and reconstruction speeds that are now possible with the X-ray CT manufacturer’s modern systems. Target markets are plastic injection moulding and EV battery cell production.

“Offering a unique combination of precision, efficiency and non-destructive analysis, X-ray and CT are redefining metrology standards in the manufacturing industry,” says Amaral. “We expect their use to continue to expand. Their adoption not only improves product quality, but also contributes to sustainability.

“The development of further new technologies and their integration with automation and artificial intelligence promise even more advances, making these methods indispensable in industries of the future.”