Nikon had the pleasure of sitting down with Metromecanica‘s Fernando Comín, co-founder of this innovative metrology company. Comín shared insights into Metromecanica’s journey, his personal experiences in the industry, and the cutting-edge technologies they’re bringing to sectors ranging from aerospace to renewable energy.

- Can you start by telling us about Metromecanica and how it came to be?

My colleague David and I created Metromecanica in 2003, due to an opportunity which came from the aeronautic industry. At that time, the Airbus A380 was in a development phase which had identified plenty of needs in large volume dimensional control. Since then, our company has evolved into three business areas in metrology: services, automation and products. We have established three metrology centres each in Spain and France, and can also provide solutions worldwide. Today the Metromecanica staff consists of 55 employees. Our strategy for the near future is to grow as a leading company in Europe in the field of 3D automation and dimensional inspection, providing advanced turn-key solutions to various industries, but especially focusing on inline production applications. We are pursuing this direction by utilising the experience of our team and through the application of advanced technology.

- Could you share some information about your personal journey? What led you to this field?

I am from Aragon, Spain, and graduated from university with a degree in mechanical engineering. Fairly early in my working career, I realised that I wanted to travel and experience different industries, rather than operating in one factory and company. I started in the field of portable metrology, operating with laser trackers around Europe, working in factories within aerospace, automotive, and energy sectors. It was a tremendous learning experience: investigating many geometry problems and measuring large machines, tooling, and parts, helped me to gain a lot of insights into various industrial processes. This prompted me to consider setting up a business myself and so, with David, created Metromecanica. Together, we manage the company following our shared principles and strategy. Being a small and independent company providing first-class solutions to OEMs and their suppliers makes us very proud.

- Where does Metromecanica primarily operate?

Metromecanica’s primary markets are Spain and France, but we also currently export 35 percent of our business to other European countries. In addition, we also have the capability to deliver metrology services worldwide.

- And what’s your main focus in these markets?

We specialise in 3D metrology inspection and have more than 23 years of experience in this field, acting as an independent engineering company. Our priority is to understand the needs of our clients, develop fully automated solutions, and ensure their successful implementation: from initial installation to commissioning and final production support. For metrology service on the other hand, we provide a full scope of activities, including problem definition, the provision of onsite metrology and the generation of detailed reporting.

- Which industries do you primarily serve, and what’s your main focus within them?

Our main focus is in the aerospace, automotive and energy generation sectors, including nuclear, hydroelectric and wind energy.

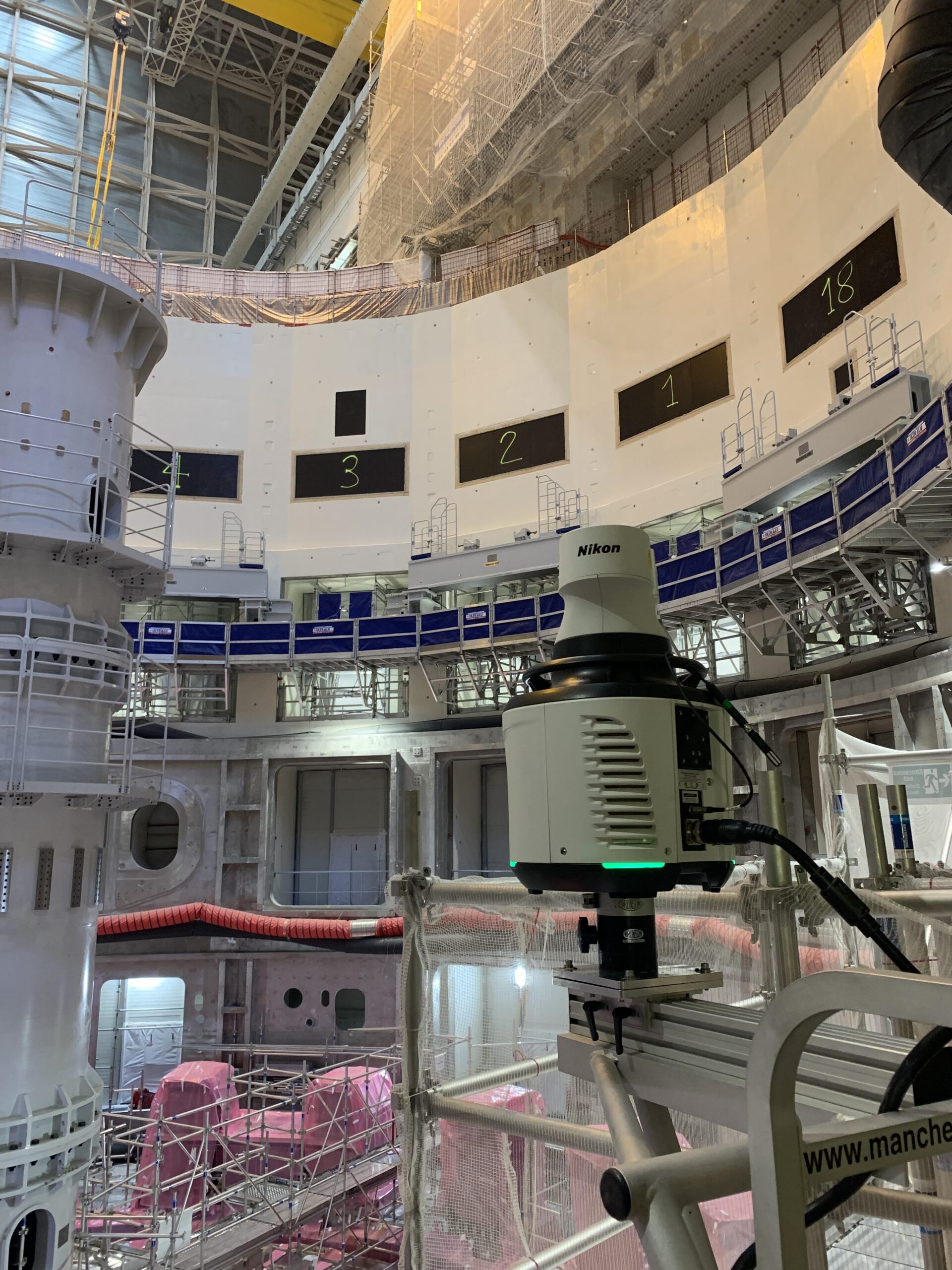

- How does the Laser Radar technology fit into your customers’ applications?

So far, we have introduced the APDIS Laser Radar technology into the energy and aerospace industries. This has been based on a number of studies and tests that we have carried out in these areas, at the request of several international corporations. The reception from customers have been impressive, as Laser Radar technology delivers many advantages, and the ROI is compelling in many cases.

- How do you typically approach and engage with potential customers?

There is no magical formula, just a usual commercial flow. One very important aspect with Laser Radar is the demonstration phase. Once a customer experiences the technology, they really believe in it and the advantages that it provides.

- What makes the Laser Radar so special in your view? What sets it apart?

That is easy to answer: it is contactless metrology, requiring no devices close to the parts, and delivering accurate data, which is both fast and stable, in addition to being simple to automate. When your background is large volume metrology, and you have experience in touch-probe CMM’s, laser trackers and many other sensors, using Laser Radar technology makes you realise that Laser Radar is in another dimension.