Today we speak to Christophe Lallement, Service Engineer within the Laser Radar Business Unit Europe, about his responsibilities and his expertise on the APDIS Laser Radar.

Could you please tell us your responsibilities within Nikon Metrology?

As a service engineer, I am in charge of all after-sales activities on Laser Radar (LR) products. There are several activities to be managed throughout the lifetime of the product. It starts with the installation of a new Laser Radar at the customer’s site and supporting tasks regarding the use of LR in their production environment. Another main activity is to perform periodic calibration and verification of the system to certify that the product still meets all specifications in terms of accuracy and reliability. Finally, I am in charge of repairing our products if problems arise during their use by the customer. As you can guess, this is the most challenging activity because we have to ensure a short response time to avoid or limit customer production downtime.

What are the best parts of your job?

When you work in after-sales service, especially with the Laser Radar, you are often traveling to customer sites, and I have the opportunity to meet many great people with whom I try to build partnerships in order to enhance our client-customer relationships. In addition, it is very interesting to install our products in new environments within the world of metrology and to facilitate the change of online measurement such as we do in the automotive industry.

Any anecdote that you would like to share with our readers?

I remember that one day I had to go to a customer site in Sweden to assess whether the factory area could be suitable to install a cell equipped with a LR. When I arrived at the factory, the customer showed me the shopfloor. Surprising to me was that the area where they wanted to install the cell had a strange construction: a sort of closed round area, which, it turned out, actually hid the toilets and the restrooms! We installed the Laser Radar system and started to monitor and assess the vibrations in the area. During this monitoring, people came to see us (and use the restrooms) but they never understood why we made them stop walking, as they couldn’t necessarily see any actual measurement going on. Long range, automated, laser-based measurements are not very visible unless you look at the computer screen, or happen to see the head move. Convincing people that you are actually measuring is difficult when, its visible strengths are elsewhere!

You travel to many customer sites for service, maintenance and installations, what are the main benefits customers experience from using the Laser Radar?

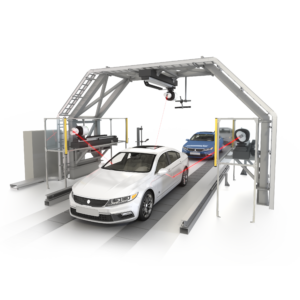

One of the best advantages of Laser Radar is that you can measure a part directly without needing to touching it or without a specific target attached to the part. To that, you add the ability to install the LR on a robot and you have a fully automated system that can measure almost any part from a distance. We can simply say: From your computer, you target the part where you want to scan, you start the measurement and you have your result. No more preparation on the parts! Therefore, most of our cells at customer sites are dedicated to the in-line quality control of large parts.

What sectors & industries can benefit from using it?

I think the Laser Radar is suitable for any applications that need to measure specific characteristics, such as features, on medium to large parts. Today, the main sectors are the automotive industry (body-in-white or large components like doors or underframe parts). We are also present in aeronautics and aerospace companies that produce even larger parts like wings or rocket fuel tanks, for example where there is a lower production rate but are products with high added value.

As a Nikon Metrology Service Engineer, what is your favorite system feature of APDIS & why?

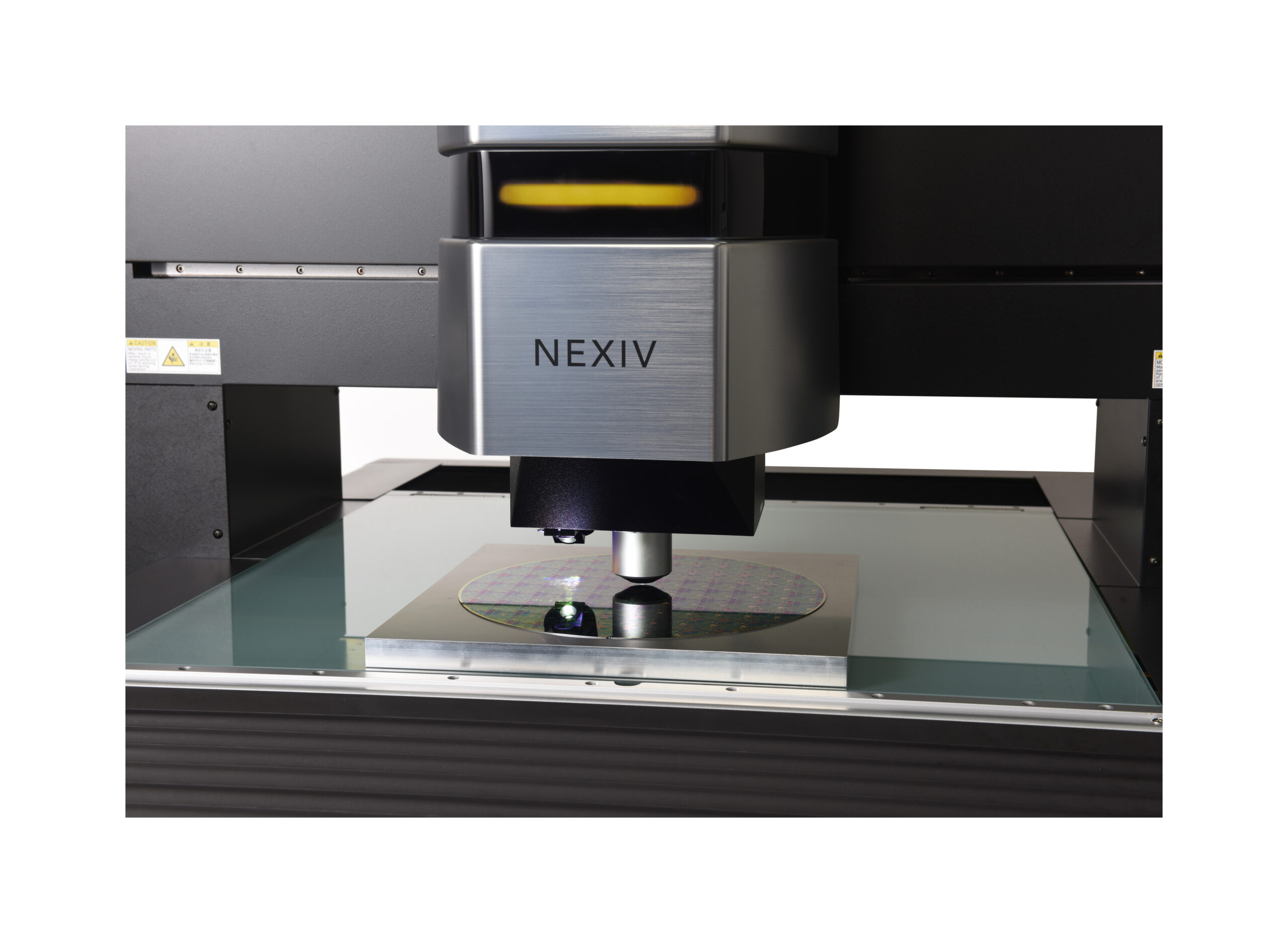

APDIS is the latest version of our Laser Radar, with strong improvements in usability and optimization. My favorite feature of the system is the installation of a new HD video camera which is fed through the Ethernet connection. This is a real advantage in terms of usability and accessibility because you can remotely control and view measurements from any computer connected to the same network with a very clear picture of what is being measured. This is another step forward in the digital age.

Learn more about our APDIS Laser Radar system and the positive impact that you will gain regarding the quality control.