Nikon’s NIS-Elements transforms industrial microscopy through robust colour recognition, PCB inspection, and particle analysis tools. This versatile platform enhances quality control and process optimisation across diverse manufacturing sectors.

Nikon’s NIS-Elements, a universal software platform, integrates robust tools for image acquisition, analysis, visualisation, and data sharing. Featuring fully customisable user interfaces and software modules, NIS-Elements can function as a straightforward interface for photo documentation or drive intricate, conditional workflows with automated imaging and analysis routines.

Colour recognition

With its sophisticated image processing algorithms, the Nikon NIS-Elements platform enables fast and automated analysis and decision-making. As a result, customers benefit from improved productivity, reduced costs, and enhanced product quality, underscoring the indispensable role of colour recognition in optimising industrial processes and driving innovation.

Colour recognition, a crucial aspect of industrial microscopy, is pivotal in quality control and process optimisation across diverse industries. Nikon’s NIS-Elements empowers manufacturers to accurately identify and assess subtle variations in colour, texture, and surface characteristics of materials, enhancing their control over product quality.

This feature can be utilised in the manufacturing process in many industries, including automotive, pharmaceutical, and much more. It minimises waste and enhances product integrity.

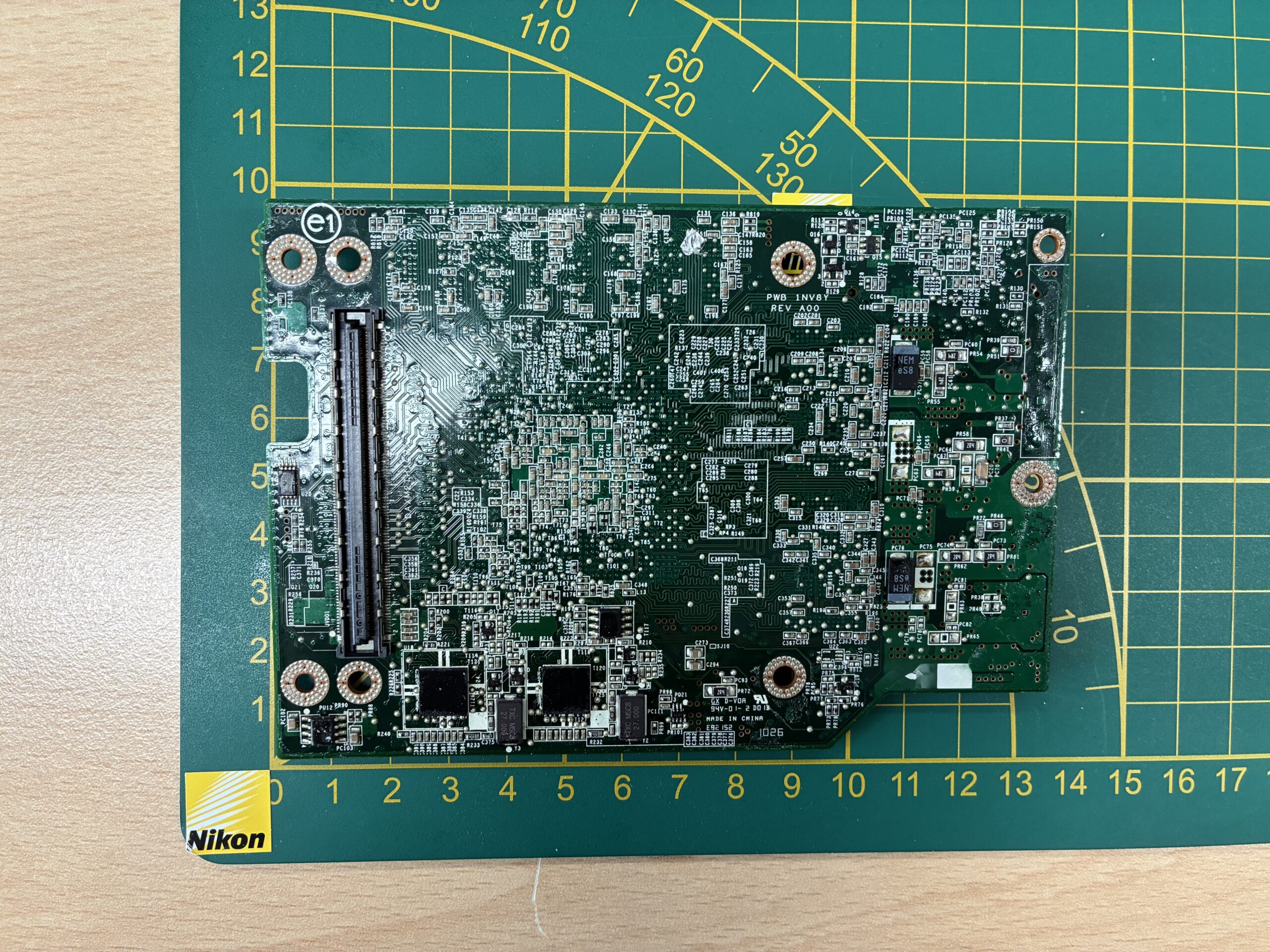

PCB via inspection

Optical inspection plays a pivotal role in ensuring the quality and reliability of electronic components on Printed Circuit Boards (PCBs).

Nikon’s automated microscopy inspection systems help identify component misalignment with unprecedented precision and efficiency, and NIS-Elements improve inspection accuracy and throughput.

Nikon’s inspection solutions streamline the inspection workflow, allowing for the rapid identification and correction of defects during production. These advancements can improve the quality and reliability of electronic components and reduce manufacturing costs and cycle times.

Nikon’s NIS-Elements software accelerates and improves inspection processes

Particles analysis

The cleanliness of components, parts, and fluids is a central issue in manufacturing. Residual contamination on manufactured parts can lead to misfunctioning and low system durability. Thus, the inspection of the cleanliness of produced components has become a standard in quality control, mainly in the automotive, aerospace, electronics, and hydraulic system manufacturers.

The NIS.ai module within Nikon’s NIS-Elements software aids in identifying particles, defects, and structures during inspections. This enables users to detect and classify relevant objects in their microscope images, even under difficult contrast conditions. With just a few clicks, operators can train a custom neural network to analyse images according to their specifications, achieving accuracy comparable to human interpretation.

If you would like to know more about any of the features outlined here, please contact our team for further information.