This month, Dr. Andrew Mathers (X-ray CT Project Manager) scanned a dry powder inhaler.

X-ray CT enables us to non-destructively inspect a wide range of drug delivery devices, to check not only the assembly quality of the entire device but also the build quality of each individual component in micron level detail!

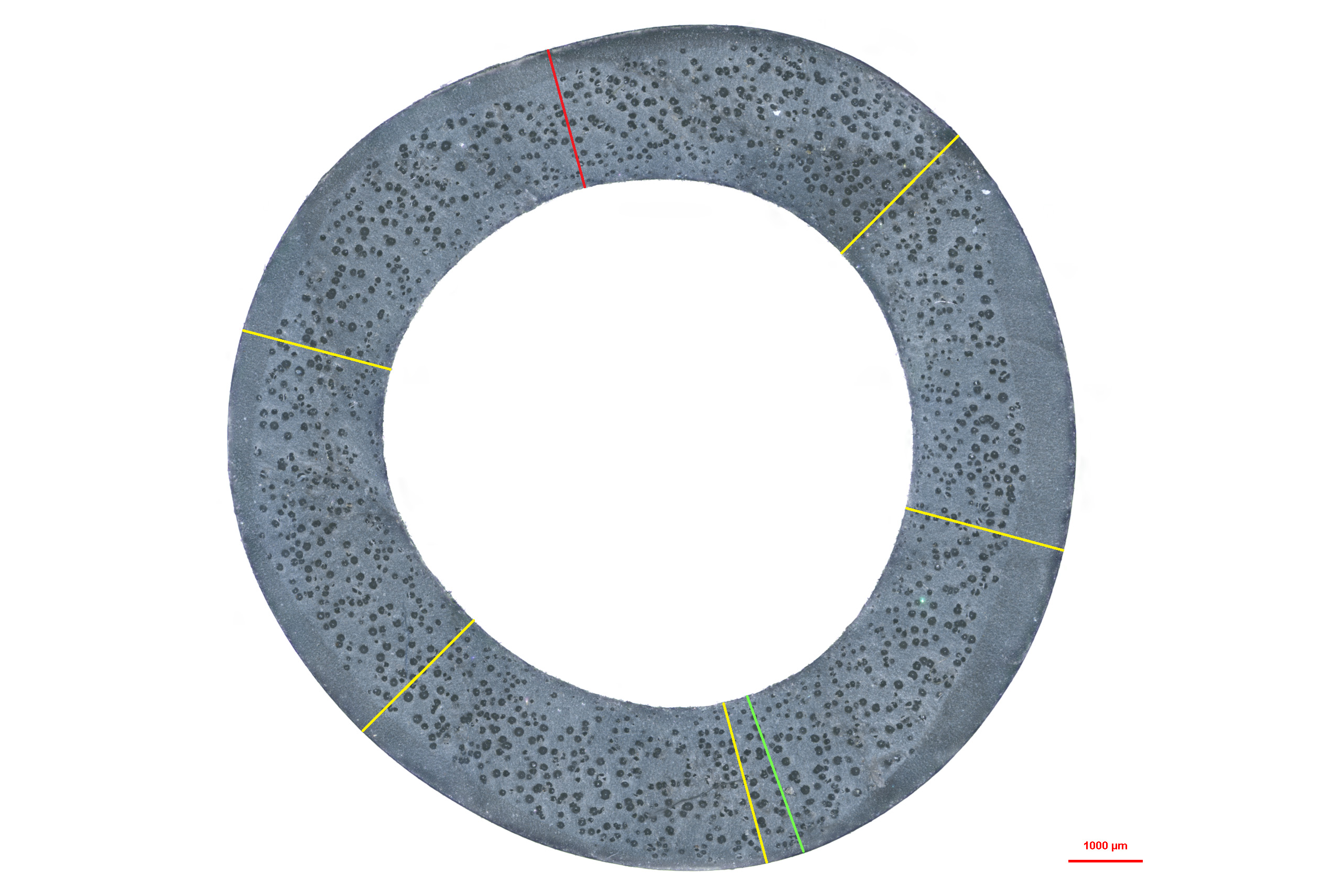

The clipped 3D rendering and 2D slice movie of the inhaler clearly show an abundance of porosity within many of the plastic cogs, ranging from the micron to millimetre scale.

The X-ray CT scan of the dry powder inhaler was acquired a matched X-ray power (Watts) and voxel resolution (µm) of 65, using a Nikon XT H 225. This system houses a Nikon 225 kV microfocus X-ray source fitted with a tungsten reflection target (transmission and rotating targets also available), coupled with a Varex XRD 4343CT flat panel detector. For this scan the detector acquired 1800 projections at an exposure of 125ms, resulting in a total scan time of less than 4 minutes!

X-ray CT data was reconstructed using a modified filtered back projection algorithm in Nikon CT Pro 3D and results were visualised using the isorender and Porosity/Inclusion Analysis module in Volume Graphics Studio Max 3.5.