The Industrial Metrology Business Unit of Nikon Corporation (https://industry.nikon.com) continues to demonstrate its commitment to supporting production line inspection and measurement. Its latest new software development, Nikon Automation OPC UA Interface, simplifies the way diverse hardware and software on a shop floor – such as a manufacturing execution system, statistical process control system or handling robot – communicate directly or indirectly with Nikon’s X-ray CT (computed tomography) machines.

The company’s existing systems in production lines use an in-house developed IPC interface, which requires working knowledge of the X-ray CT system and a software developer who understands the Nikon IPC contract. While this interface remains in the software for intricate control of all aspects of the system, applications on the shop floor are now supported by the industry-standard, platform-independent OPC UA interface. It means that integrators with knowledge of it are able to integrate third-party industrial, automation and control equipment more easily. Therefore both time and costs are saved when installing or reconfiguring production line systems within a single factory, or across multiple connected facilities around the globe.

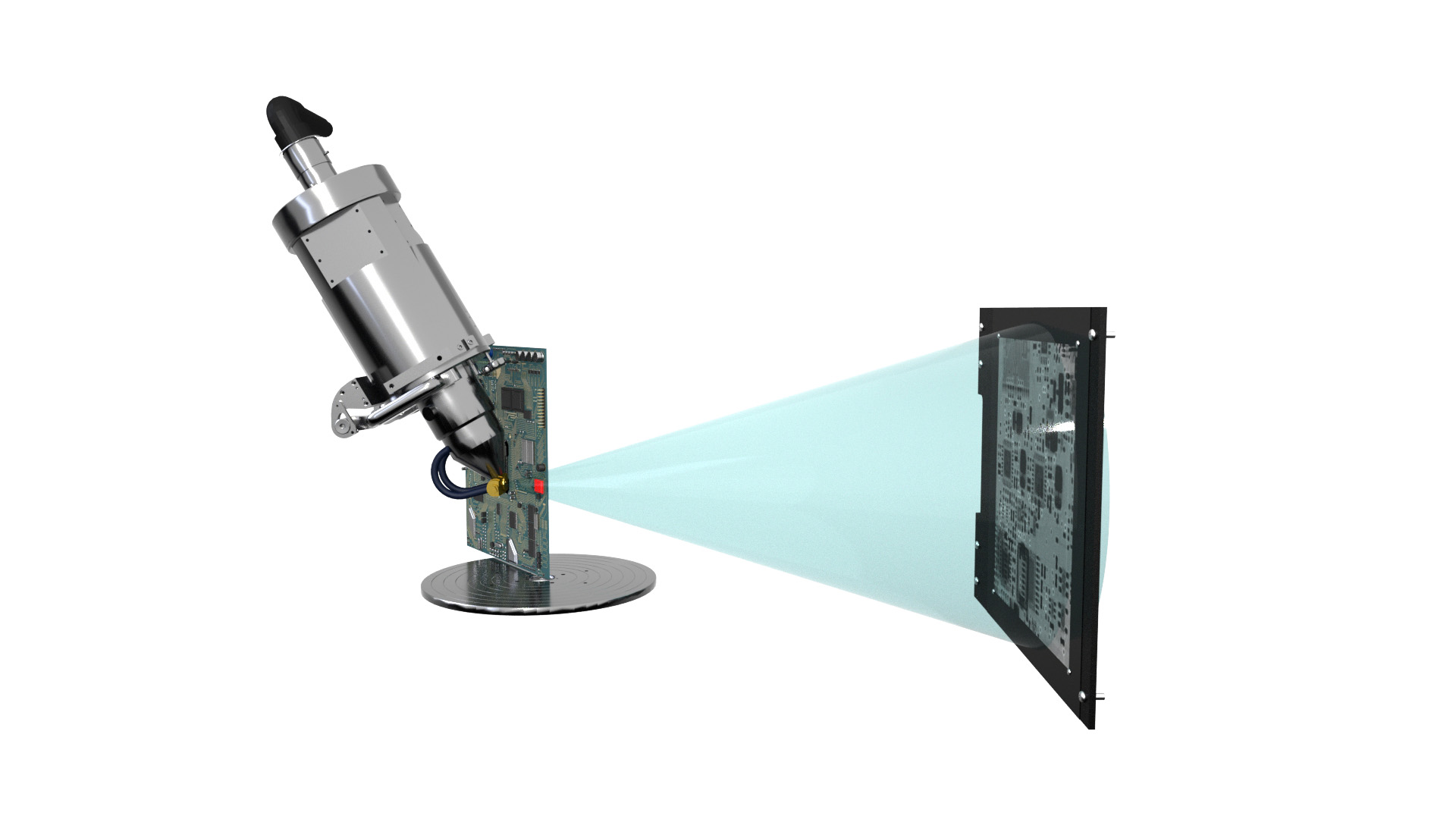

Nikon’s alignment with the industry-standard OPC UA communication protocol reaffirms its dedication to developing fully automated, non-contact, X-ray CT quality control systems for the shop floor. There is a growing, industry-wide trend towards using this technology for feeding back data in real time to optimise production line operation – the goal being zero defects. X-ray CT is especially relevant, as it is able to inspect and measure the interior of components non-destructively as well as the exterior.

The approach whereby inspection drives production rather than just identifying faulty parts is called Quality 4.0. The OPC UA interface is now one of the main communication protocols for networking within Industry 4.0 factories, as a common language is needed to simplify secure data exchange between computer-controlled machines and systems, and that is exactly what OPC UA delivers. Nikon is therefore delighted to be one of the first X-ray CT system vendors to implement it. For more information, click here.

About Industrial Metrology Business Unit

Nikon provides a variety of products, services, and solutions worldwide, based on advanced opto-electronics and precision technologies cultivated during the company’s more than 100 years of history. The group continues to create new values that contribute to improvement of quality of life and manufacturing in a wide variety of forms. Nikon’s Industrial Metrology Business Unit (IMBU) delivers integrated, optimised, ultra-high precision solutions that are not only customised and cost-effective but also work extremely well as soon as they are implemented. A recent development under Nikon’s Digital Manufacturing banner is closer cooperation between IMBU and the corporation’s Digital Solutions Business Unit (DSBU), which has launched a series of optical additive and subtractive manufacturing solutions for processing a wide variety of materials to sub-micron surface finish. www.industry.nikon.com

On behalf of:

Nikon Metrology

Building 424, Argosy Road, East Midlands Airport, Castle Donnington, Derby

Contact: Ghislaine Burmeister

Tel: +44 7827 668763

Email: [email protected]

Web: www.industry.nikon.com

Issued by:

The Right Image Ltd

PO Box 42, Twickenham, TW1 1BQ

Tel: +44 (0)20 8891 0603

Contact: Chris Wright

Email: [email protected]

Web: www.therightimage.net