Products and promotions may differ based on your selected region.

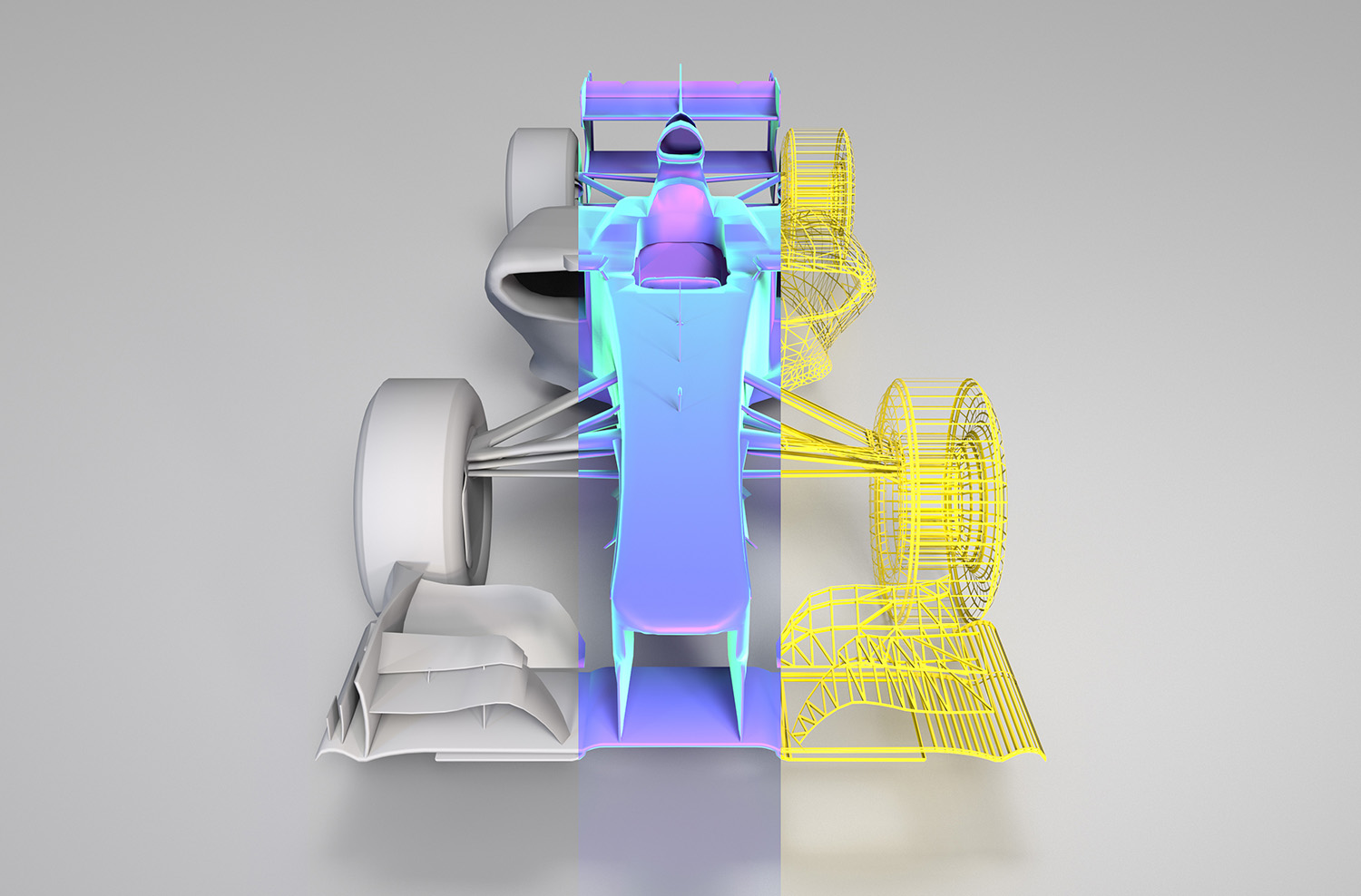

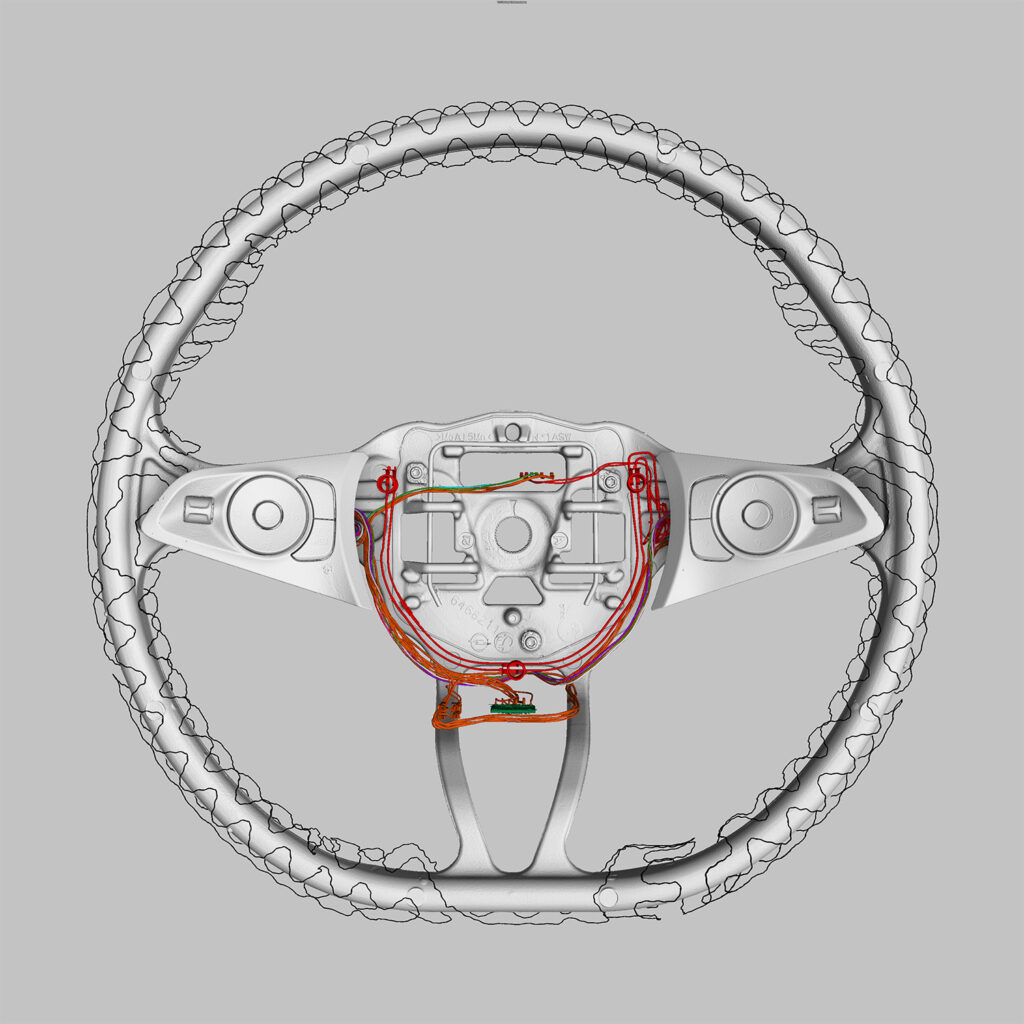

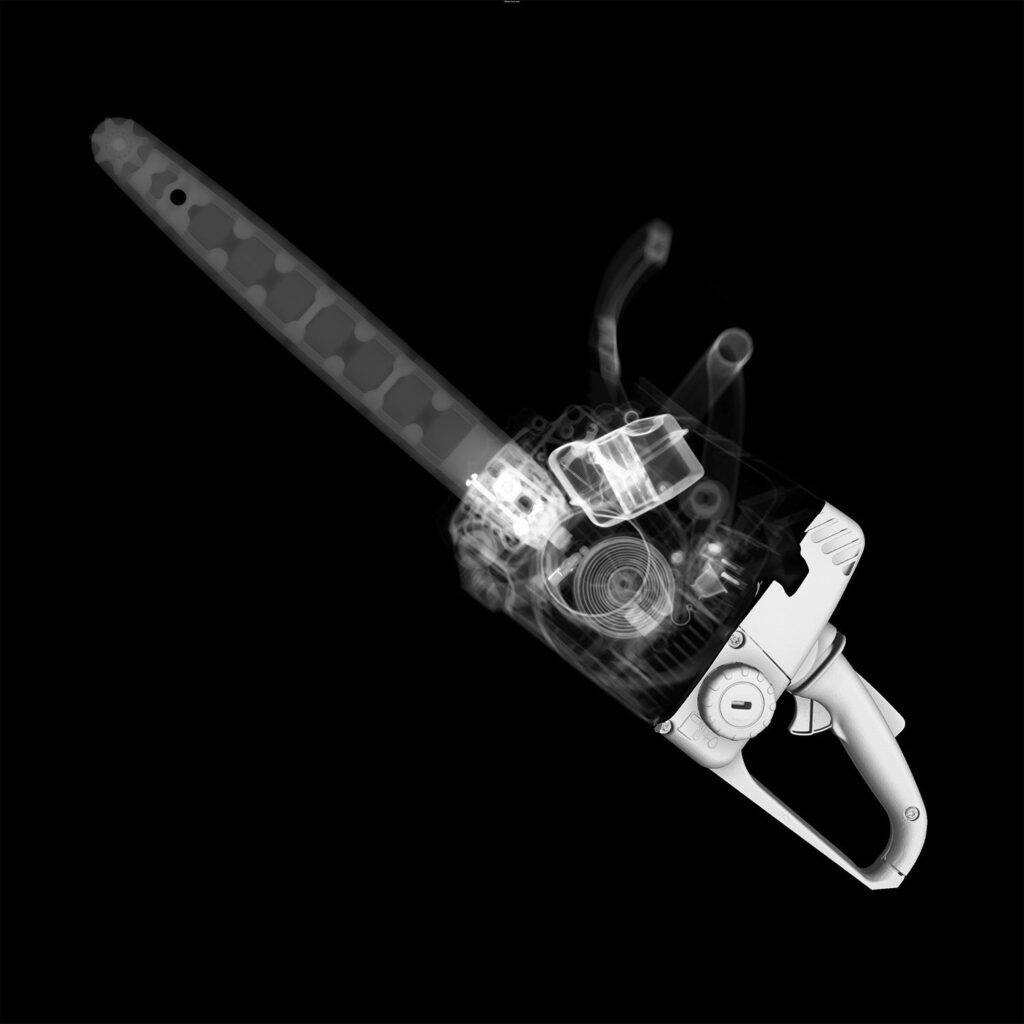

Nikon’s versatile, large-envelope X-ray and CT systems can inspect items of diverse size and density, internally and externally, enabling them to perform virtually limitless tasks within industry, inspection bureaux and academia.

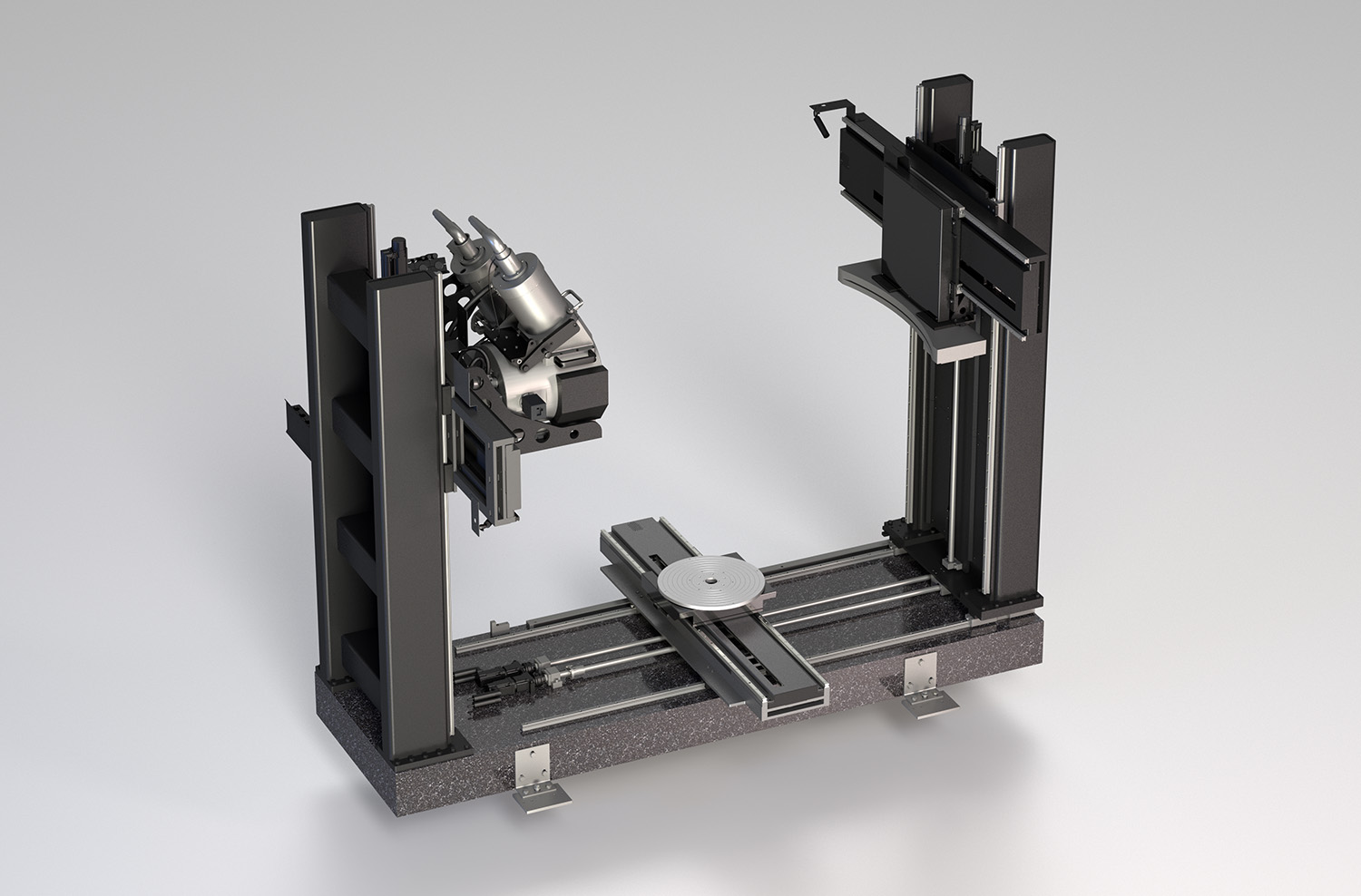

Nikon’s large-envelope system range combines metrology grade, granite-based manipulator construction with a large scanning volume, multi-source flexibility, dual detector functionality and an extensive range of CT acquisition modes, enabling them to excel in any inspection environment, from R&D labs to the shop floor.

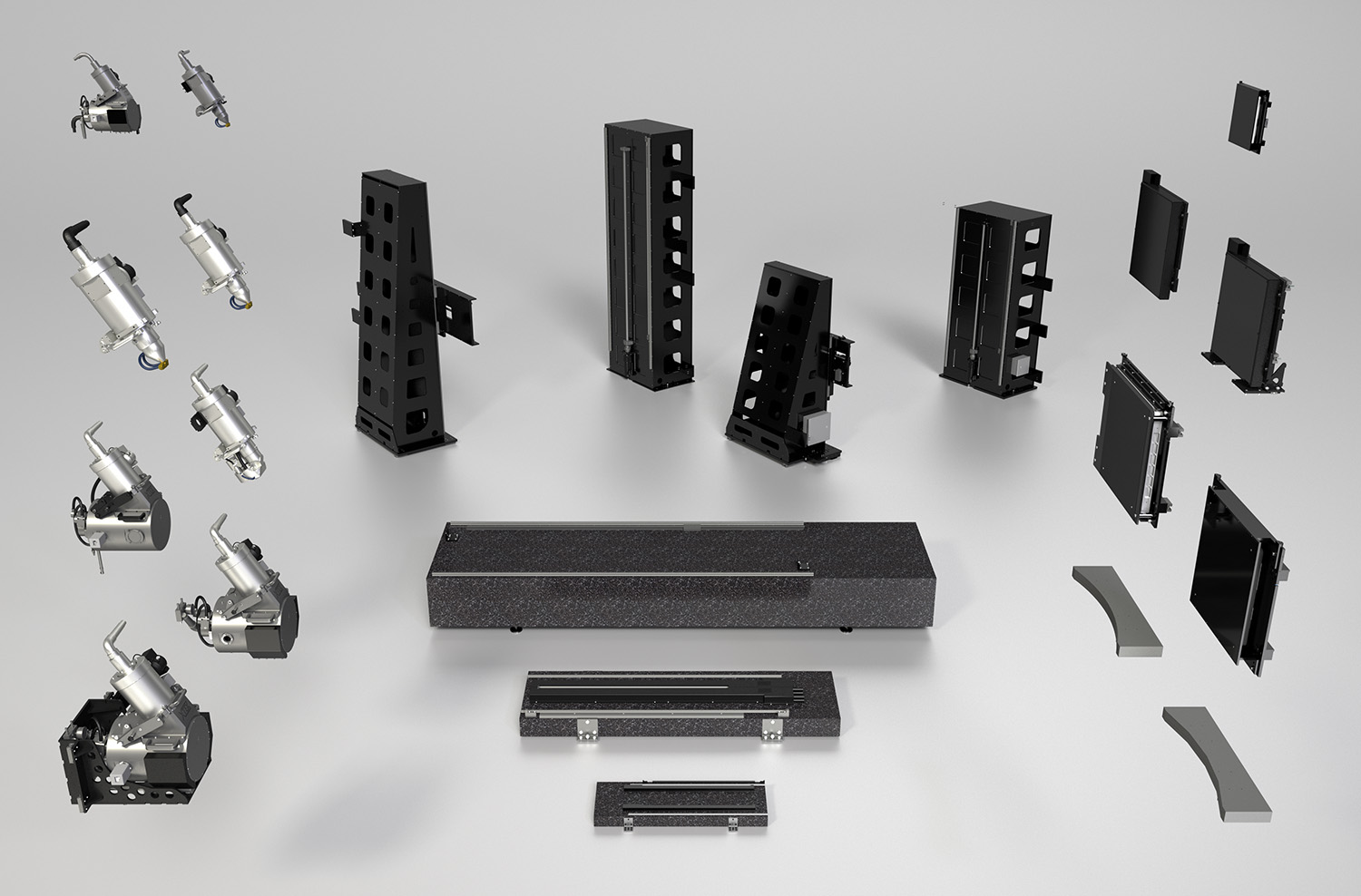

With 8 different X-ray sources, 7 detectors, 3 granite base lengths and 2 manipulator constructions to choose from, housed in either a single-piece cabinet, panelised room or pre-existing shielded enclosure, you’ll find a system configuration to match your requirements.

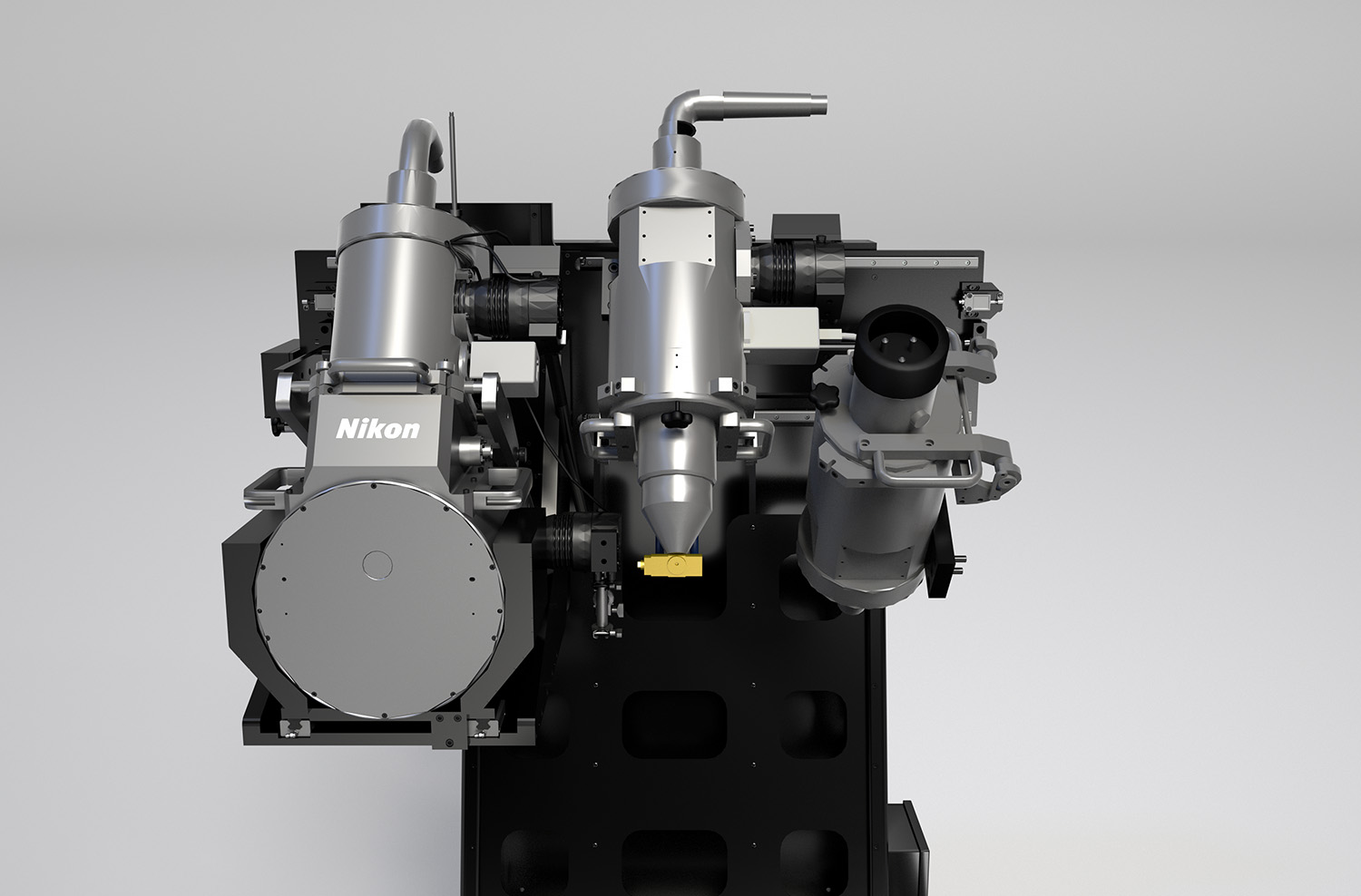

Select up to 3 X-ray sources from Nikon’s extensive microfocus range to ensure you have the optimum combination of penetrative power, resolution and scan speed for all your applications.

A choice of industry-leading, flat panel detectors with small pixel sizes and fast exposures, combined with Nikon’s unique CLDA, enables high-throughput CT and DR for all part types, plus advanced scatter correction for high-density parts.

Our granite-based manipulators are combined with rigid towers and precision motors and encoders. The resulting construction ensures superior mechanical and thermal stability, leading to enhanced positional accuracy and repeatability.

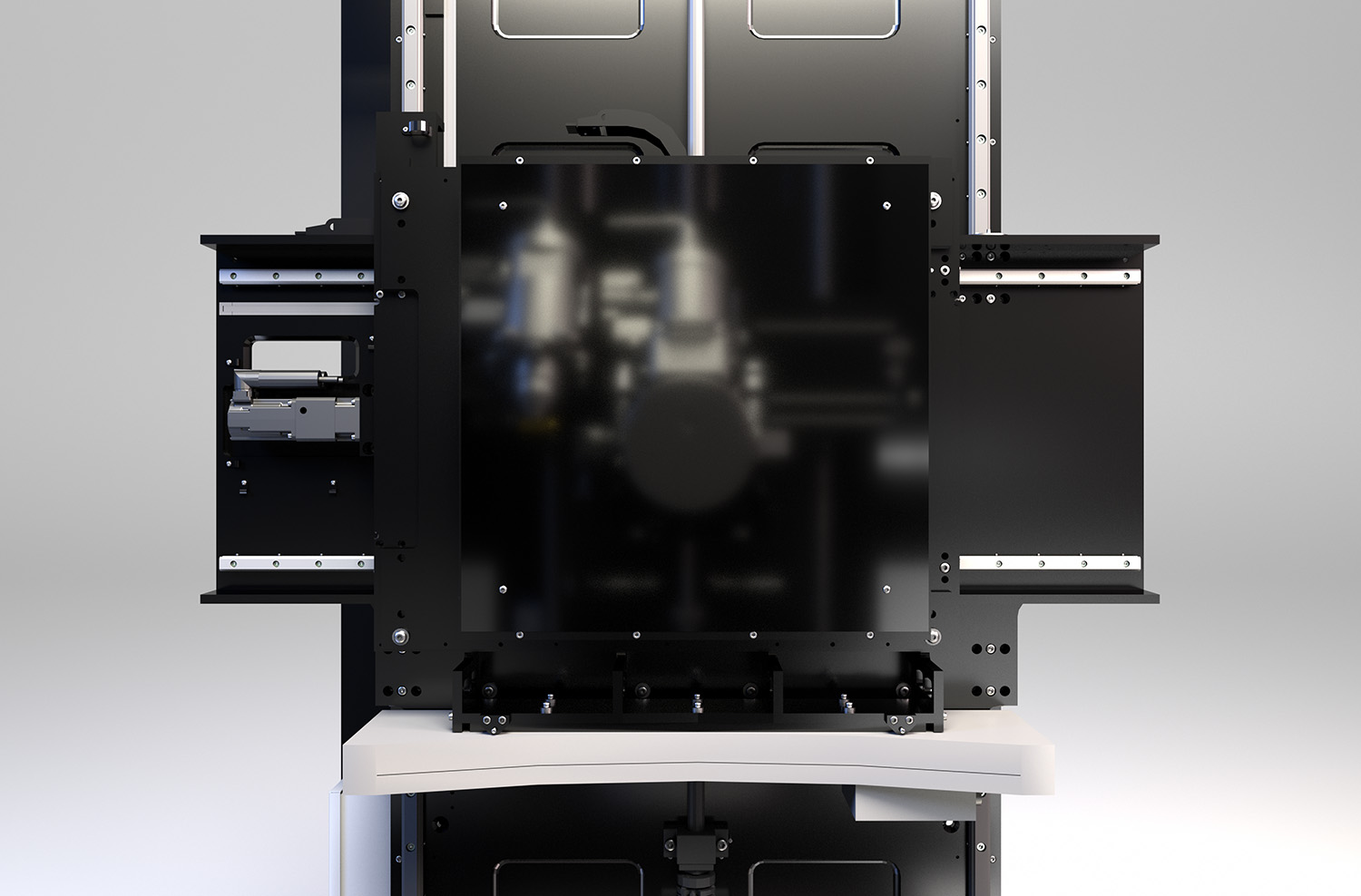

With up to 4-position panel shift and synchronous Y-axis source and detector movement, the maximum available scanning envelope can accommodate samples up to 1000 mm swept diameter and over 1500 mm tall.

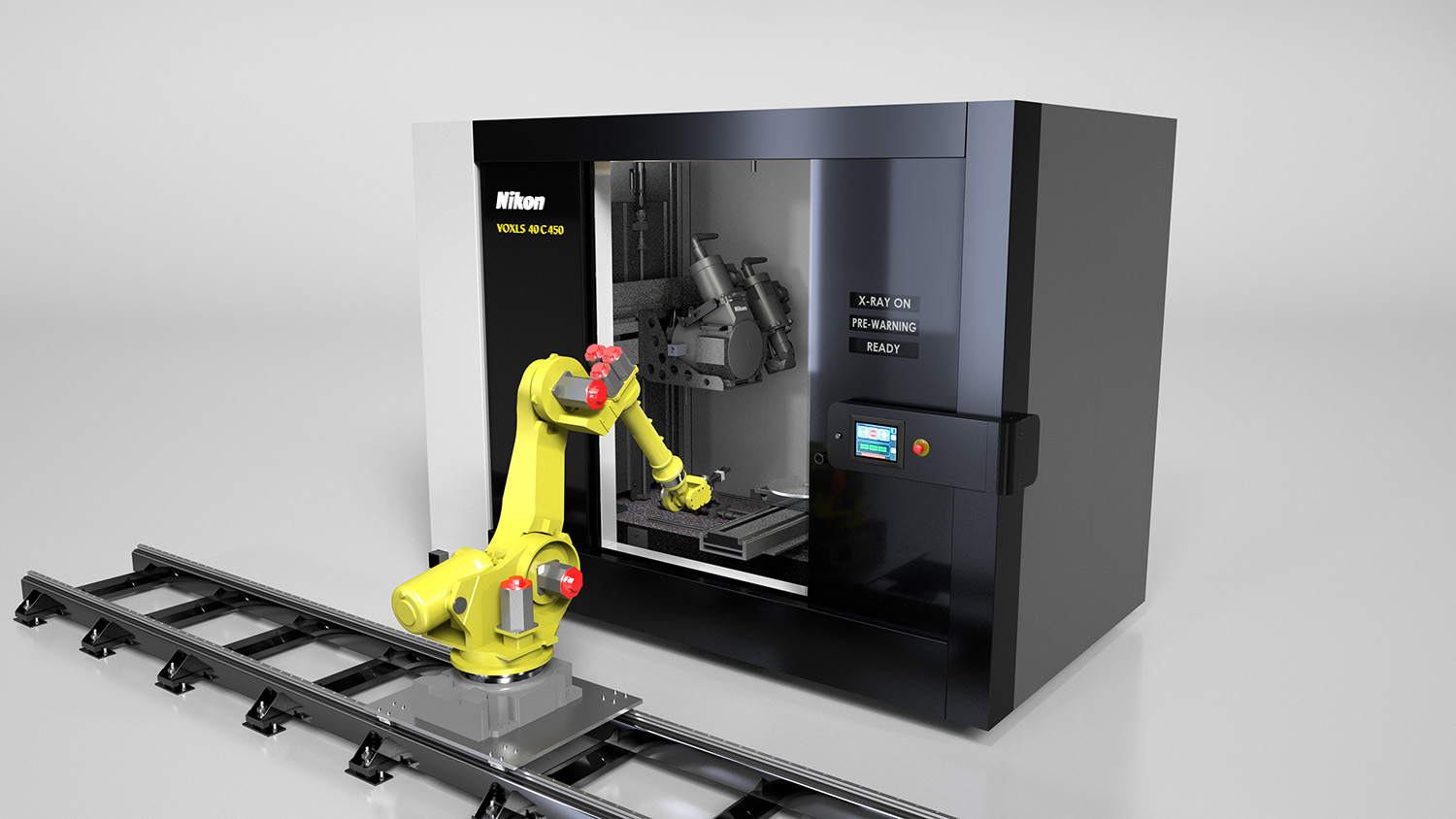

When combined with an integrated robotic loader and the Nikon Automation OPC UA Interface, our large envelope systems are automation ready for closed-loop inspection at high speed in a Quality 4.0 production line environment.

For ease of installation and relocation, the VOXLS 40 C 450 and M2 models are available in a single-piece cabinet enclosure as standard, whereas the ultra-large format C2 and C3 are housed in a modular panelised room. Alternatively, all systems can be offered as manipulator-only configurations for a pre-existing enclosure.

If you would like further details on this product or a more in-depth description, our expert team will provide you with additional information and, if required, arrange an on-site visit. Talk to us in detail about your project and our experts will advise you on the best inspection system to meet your requirements. Please fill out the form opposite and we will get in touch with you shortly.