Nikon has introduced the NEXIV VMF-K Series, a high-performance video measuring system that significantly improves measurement throughput.

TOKYO – Nikon Corporation (Nikon) has launched the NEXIV VMF-K Series, a next-generation video measuring system designed to meet the increasing semiconductor and electronic component inspection demands.

Building upon the success of the VMZ-K Series, the NEXIV VMF-K Series offers significant benefits to a wide range of industries in addition to semiconductor manufacturing, including advanced packaging, substrate production, wafer inspection, and probe card inspection.

As semiconductors become smaller and more integrated, inspection processes are increasingly crucial for quality maintenance. The NEXIV VMF-K Series addresses this challenge by providing stable measurements of micron-level dimensions while significantly improving throughput, thereby supporting stringent quality control in semiconductor device manufacturing.

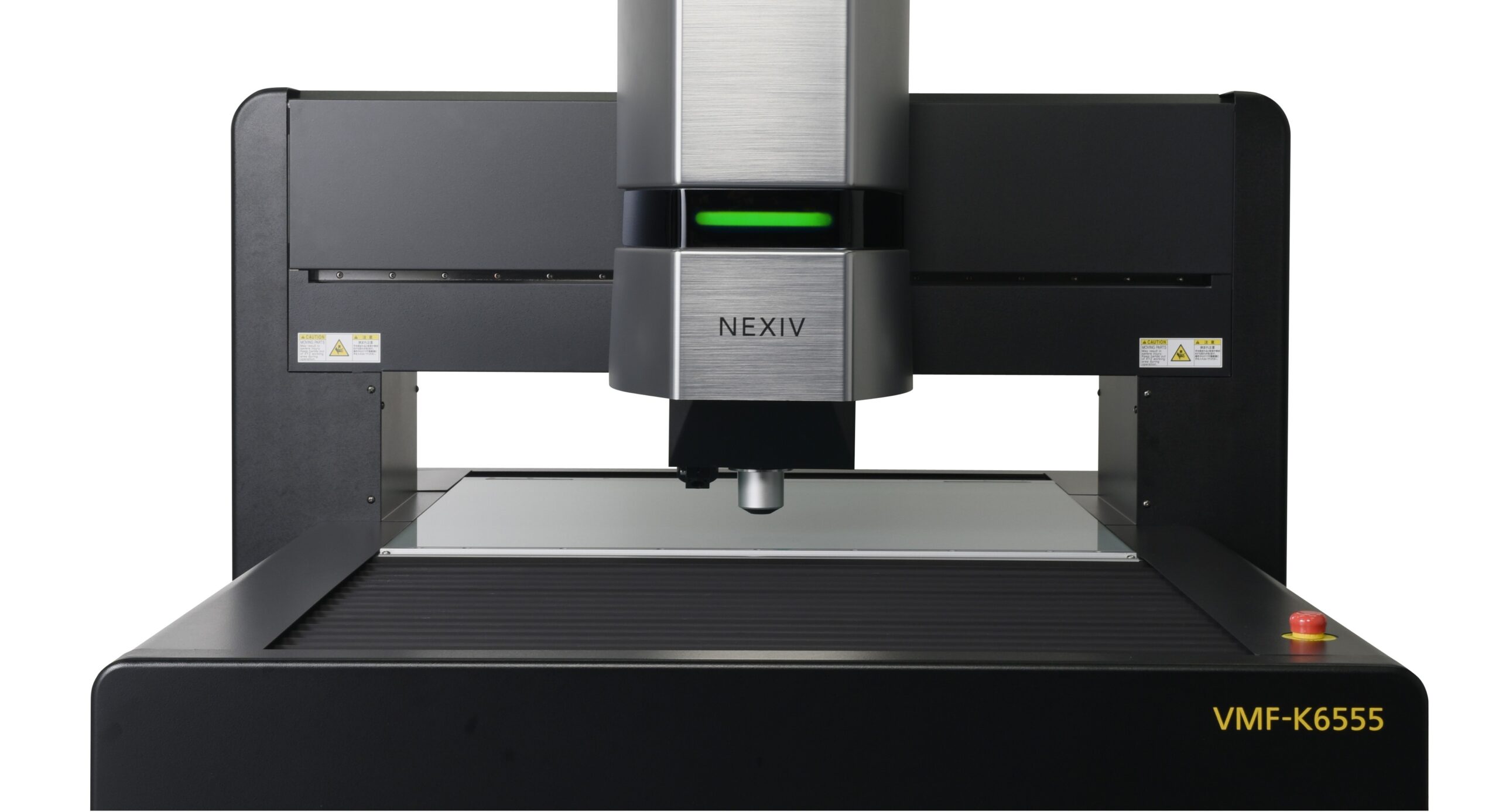

The new NEXIV VMF-K Series consists of the VMF-K3040, which replaces the VMZ-K3040, and the VMF-K6555, which replaces the VMZ-K6555.

Key benefits of the NEXIV VMF-K Series include:

- Enhanced measurement throughput: The VMF-K Series achieves approximately 1.5 times higher measurement throughput compared to the previous VMZ-K model (according to Nikon’s standard measuring conditions), significantly reducing measurement time and boosting productivity.

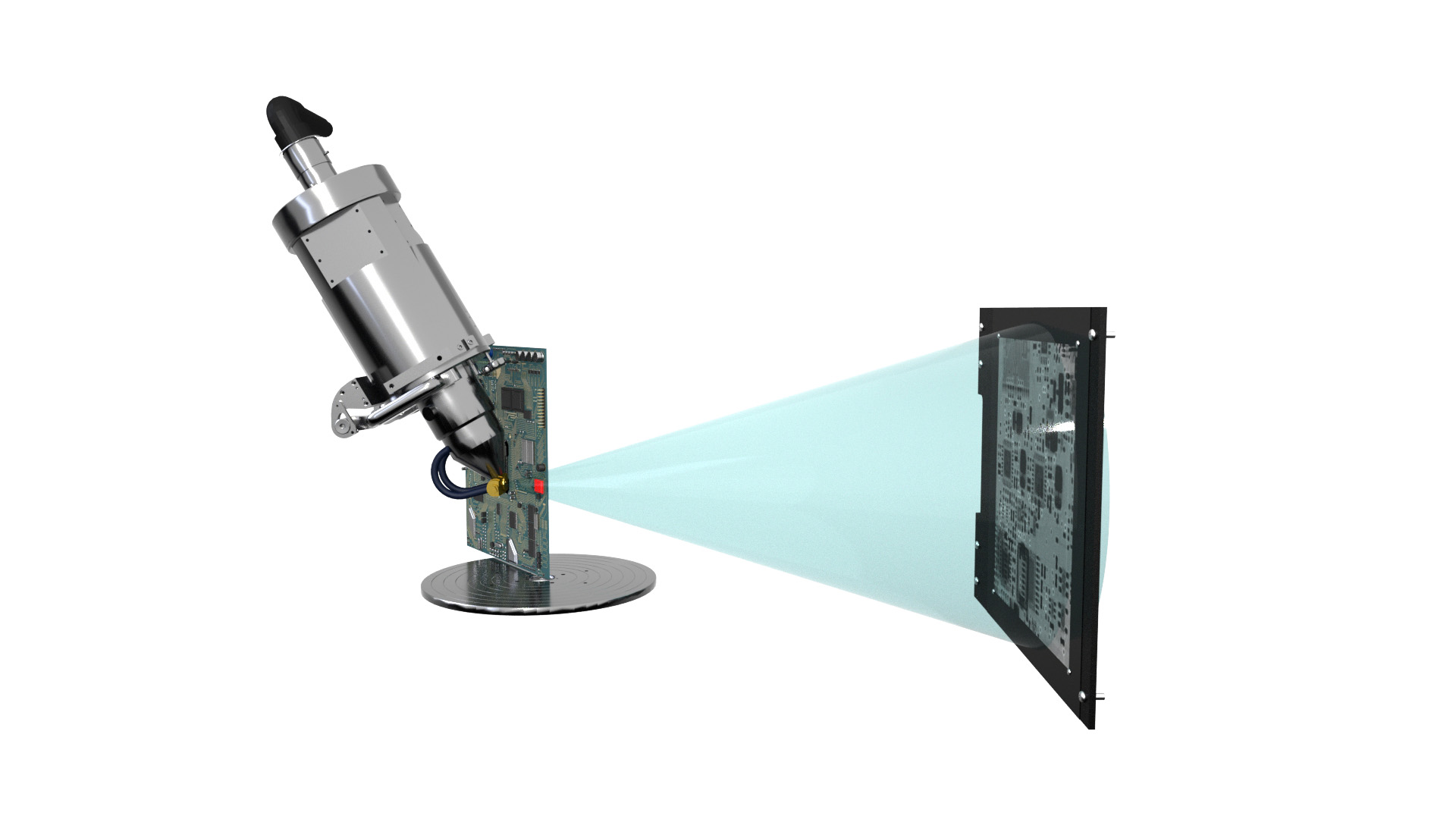

- Advanced optics: Equipped with a confocal optical system, the VMF-K Series enables simultaneous 2D and height measurement within the field of view, achieving significantly higher throughput compared to height measurement using only bright-field images.

- Improved light source: The confocal light source has been changed from a xenon lamp to an LED, increasing lifespan from 3,000 hours to 30,000 hours. This enhancement improves operational efficiency and reduces the need for lamp replacements.

- Expanded model lineup: The series now includes a standardised 45x objective lens model, supporting advanced semiconductor measurement demands for even finer measurements.

- SEMI S2/S8 compliance: The VMF-K Series meets industry safety standards for semiconductor manufacturing equipment when installed appropriately according to the SEMI S2/S8 guidelines.

- New software function: The series offers the ability to display the remaining time during measurement.

- New exterior design: The series features a sleek factory design with black and silver tones.

“We are delighted to introduce the NEXIV VMF-K Series, an industry-leading solution that addresses the growing needs for high-speed, finer measurement in semiconductor and electronic component manufacturing,” said a Nikon spokesperson.

“By significantly improving measurement throughput and maintaining high accuracy, our new system empowers manufacturers to enhance their quality control processes and accelerate product development in the face of increasing miniaturisation and integration of semiconductor devices.”

About Nikon’s IDSBU

Nikon’s Industrial Solutions Business Unit (IDSBU) is a cornerstone of the company’s B2B operations, formed through the strategic merger of the Digital Solutions Business Unit and Industrial Metrology Business Unit. The IDSBU delivers comprehensive industrial solutions ranging from high-quality optical components to sophisticated measurement and inspection systems. The unit draws on over 100 years of Nikon’s advanced applied optics and precision technology expertise to deliver innovative solutions worldwide. Editor’s note: IDSBU is the official abbreviation for Industrial Solutions Business Unit, based on the English translation of the division name. www.industry.nikon.com