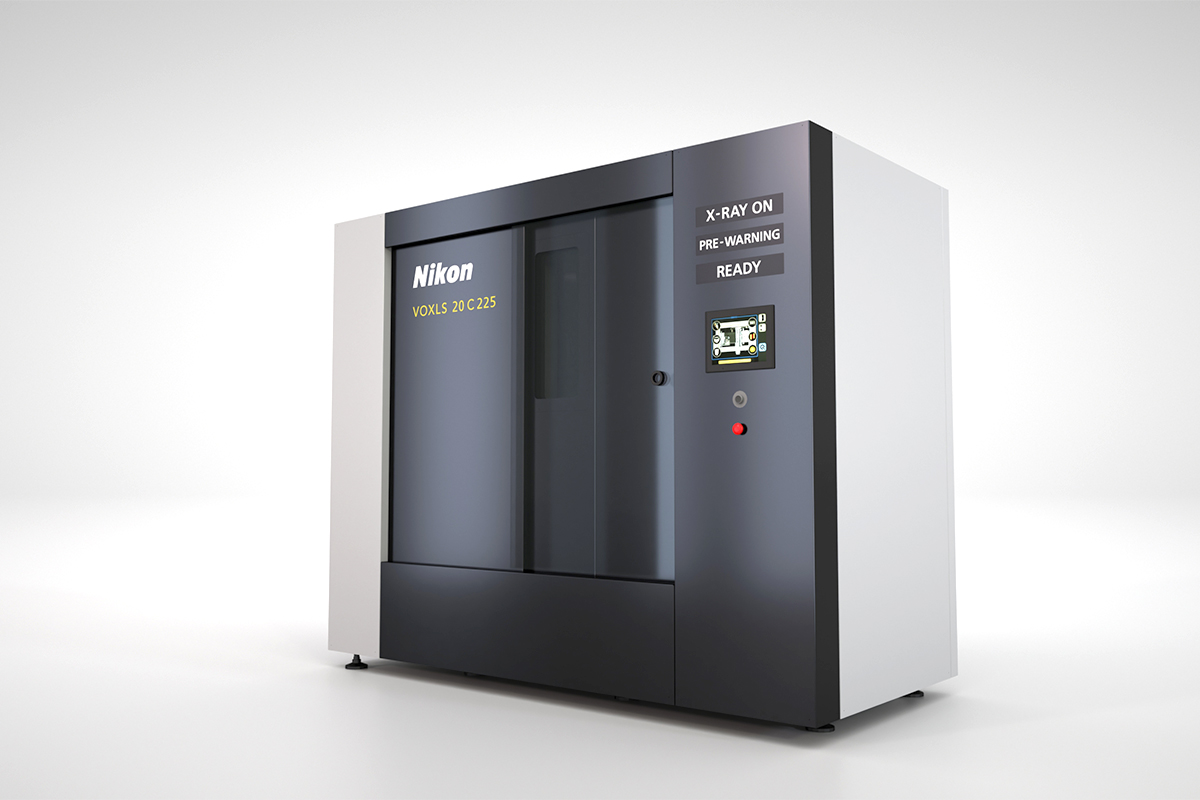

Nikon’s versatile, space-efficient X-ray CT system delivers best-in-class CT inspection envelope and exceptional data quality for advanced industrial quality control.

Nikon Corporation (Nikon) has launched the VOXLS 20 C 225, the latest addition to its VOXLS X-ray CT product lineup. This system is based on the proven principles of the company’s VOXLS 30 and 40 Series systems while offering maximum capability in a space-efficient footprint, providing unparalleled value per voxel in the market.

The VOXLS 20 C 225 offers the largest CT scanning envelope in a system that fits through a standard double door, allowing for flexible integration to almost any quality control laboratories and production environments.

The new system features Nikon’s metrology-grade platform with a granite base, rigid steel manipulator towers, and high-accuracy encoders and motors. These engineering choices ensure the precision, repeatability, and reliability that the Nikon brand is known for while delivering exceptional X-ray and CT data quality.

Key features include:

- Superior CT inspection envelope: Offers an industry-leading inspection volume of 555mm (Dia) x 759mm (H) in a compact footprint of just 2451mm (L) x 1173mm (D).

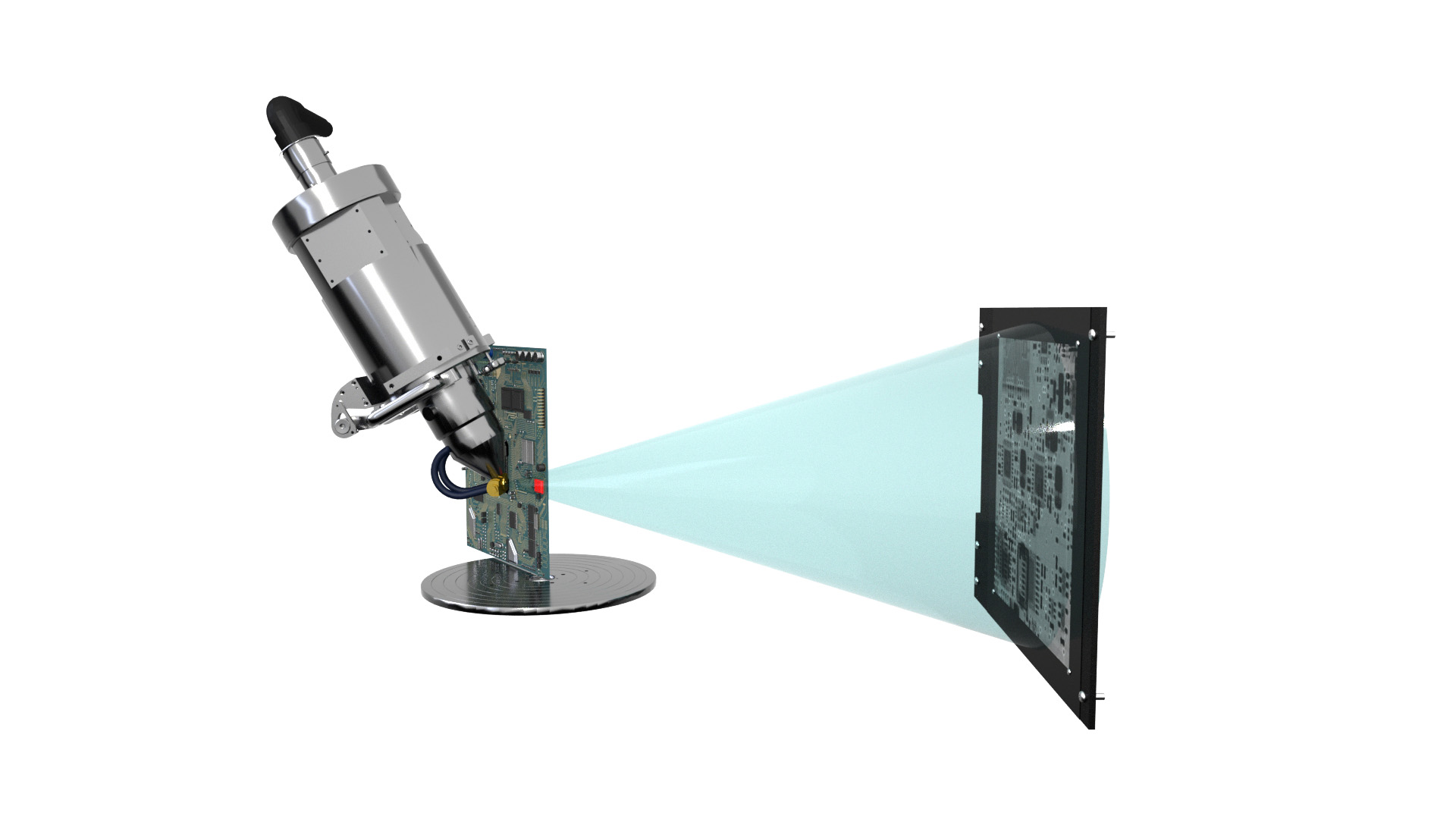

- Dual-source configuration: Features a motorised dual-source setup with a 225 kV reflection target and 160 kV transmission target, allowing users to choose the optimal source for their application at the push of a button. This enables automated and fast switchover between the reflection target (for higher productivity due to increased X-ray flux) and transmission target (for achieving the best possible resolution).

- Source Optimisation: De-skills the process of setting up the filament for optimal performance, simplifies the filament change process, and provides longer filament lifetime.

- Enhanced usability: Incorporates features like Filter Changer, motorised door that opens in under 4 seconds, and large viewing window for excellent interior visibility.

- Versatile scan capabilities: Supports Motorised FID and advanced scan modes including Panel Shift CT, Tilted CT, and Pixel Split CT, enabling a wide range of inspection techniques for diverse applications.

The first Nikon VOXLS 20 C 225 systems are scheduled for delivery this autumn and will serve industries including electronics, additive manufacturing, aerospace, automotive, and medical devices.

“Our customers have been seeking a comprehensive X-ray CT solution that combines advanced capabilities with space efficiency,” says Ben Morgan, Product Manager at Nikon. “The VOXLS 20 C 225 delivers precisely that – with its industry-leading inspection envelope, innovative features like X.Tend Helical, Scatter Correction CT, AI Reconstruction, and dual-source configuration with Rotating.Target 2.0, we’ve created what we believe is the most capable and versatile X-ray CT system in its class.”

Designed as a long-term investment, the VOXLS 20 C 225 is ready to adapt to the evolving needs of a high-end manufacturing business. Whether in the laboratory or on the production floor, Nikon’s new X-ray CT system is equipped with thoughtful technology for increased throughput and is upgradable with a range of automated and robotic inspection solutions using Nikon Automation with OPC UA Interface.

More information, including a full feature summary, is available on Nikon’s website: VOXLS 20 C 225

About Nikon

Nikon’s Industrial Solutions Business Unit (IDSBU) is a cornerstone of the company’s B2B operations, formed through the strategic merger of the Digital Solutions Business Unit and Industrial Metrology Business Unit. The IDSBU delivers comprehensive industrial solutions ranging from high-quality optical components to sophisticated measurement and inspection systems. The unit draws on over 100 years of Nikon’s advanced applied optics and precision technology expertise to deliver innovative solutions worldwide.