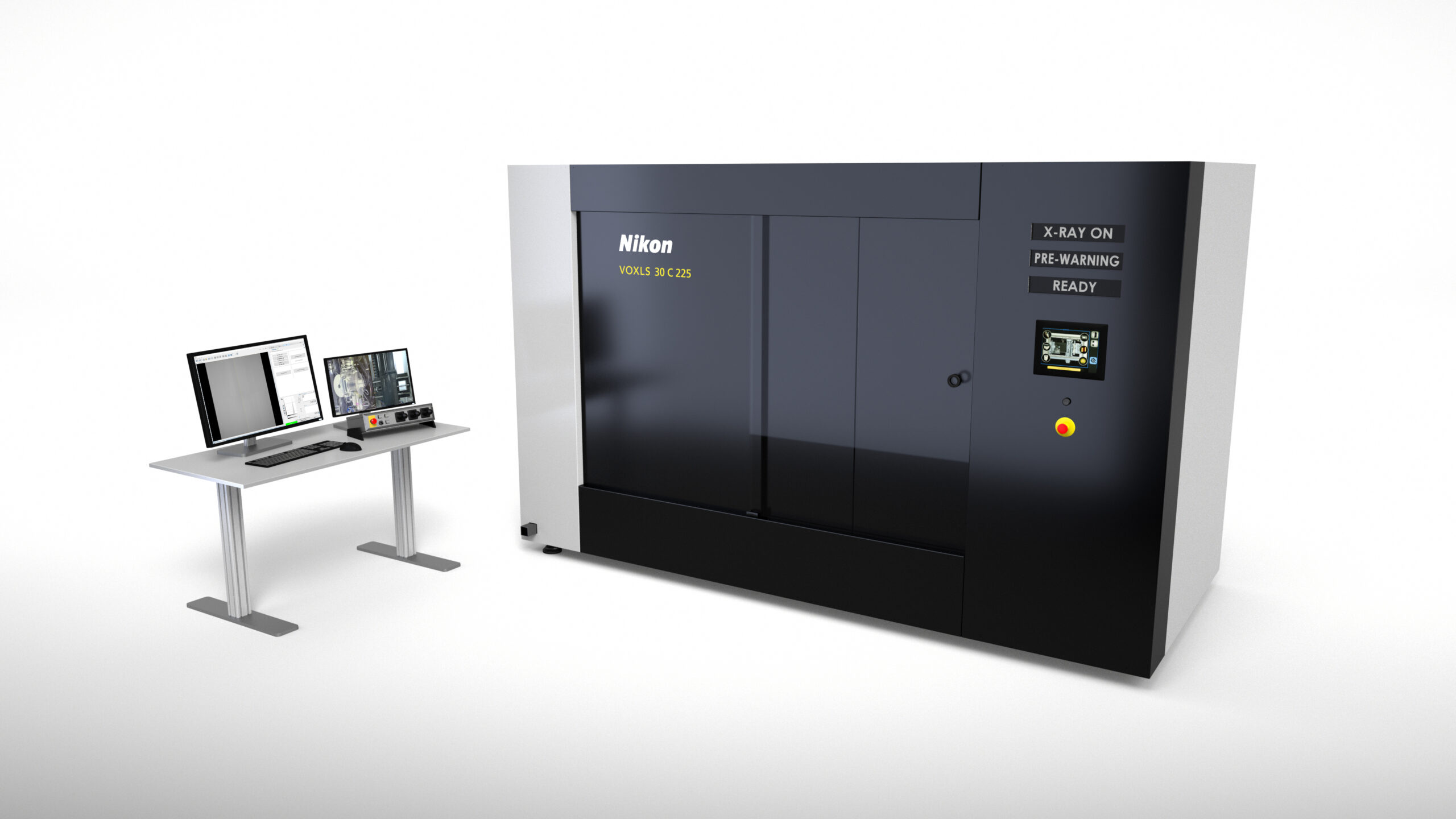

Nikon IMBU (https://industry.nikon.com) has launched three new models in its VOXLS range of X-ray CT (computed tomography) systems for non-destructive inspection. The introduction of the 30 Series fills a specific need in the industry for users looking for an automation-ready system with the versatility to meet a wide range of industrial applications.

The high-performance VOXLS 30 C 225, 30 C 320 and 30 C 450 models are now available to order and have maximum source energies of 225kV, 320kV and 450kV respectively for examining parts of various densities and sizes. They also have a more compact footprint than Nikon’s 40 Series while maintaining advanced features traditionally exclusive to larger, more expensive solutions.

The systems are designed for automated operations across the production sector, especially for quality control in factories producing lithium-ion batteries or additively manufactured components. The automotive, aerospace, medical and pharmaceutical industries are additional target markets, and many applications will also be found in materials science, natural sciences, and academia.

At the core of this series is a metrology-grade, granite-based manipulator coupled with rigid steel towers, which provides a thermally stable and solid construction. High-precision motors, ballscrew drives and encoders ensure precise positioning and accurate movement of all axes, including the synchronous vertical motion of the X-ray sources and detectors.

The 30 Series complements Nikon’s flagship VOXLS 40 C 450, a larger capacity model launched in early 2023. Both 40 Series and 30 Series systems have industry-leading design and operation is enhanced further by the manufacturer’s extensive CT acquisition technologies and reconstruction algorithms, including X.Tend Helical CT, Offset.CT, Panel Shift, Pixel Split CT, Half.Turn CT and Tilted CT.

Dr. Andrew Mathers, Nikon’s X-ray and CT Product Manager, said: “Automation at multiple levels is a major focus of the new 30 Series, from Batch CT providing efficiency gains for technicians to full factory integration with robotic handling and automated inspection via Nikon’s OPC UA Interface.”

To further facilitate automation, the systems feature motorised bi-parting radiation doors that open and close in less than five seconds, behind which the cabinet interior can accommodate items up to 1,000 mm in diameter by 1,370 mm tall. The 30 Series’ 225kV model offers an industry-leading scan volume within its size class, while all models offer impressive maximum scanning volumes of more than 600 mm diameter by more than one metre high. The systems are powered by Nikon’s proprietary X-ray source technology, including their unique 225kV Rotating.Target 2.0 and 450kV reflection target.

Dr. Mathers said: “Nikon’s Rotating.Target technology provides continuous operation even at 450 W; three times greater power density than conventional reflection targets; and significantly higher X-ray photon flux. All these factors add up to dramatically faster scan times and better signal-to-noise ratio without loss of resolution.”

The 30 Series cabinets utilise a manipulator-interlocked, glass outer door to give the operator unrivalled visibility into the enclosure when the inner radiation safety doors are open. This design enables confident positioning of the scan object, minimising the risk of collision with the X-ray source and detector while at the same time providing a physical safety barrier between the operator and the moving manipulator. Multiple internal high-resolution video cameras provide an excellent view even with the inner radiation safety doors shut and X-rays on.

Dr Mathers concluded: “As manufacturing requirements become ever more stringent, the capabilities and throughput of inspection solutions must continue to rise to meet the demand and help manufacturers realise the ultimate goal of zero-defect parts. The VOXLS 30 Series range not only enables companies to meet their current inspection needs but will also drive the design and development of higher-quality products.”

About Nikon Industrial Metrology

Nikon provides a variety of products, services, and solutions worldwide, based on advanced opto-electronics and precision technologies cultivated during the company’s more than 100 years of history. The group continues to create new values that contribute to improvement of quality of life and manufacturing in a wide variety of forms. Nikon’s Industrial Metrology Business Unit (IMBU) delivers integrated, optimised, ultra-high precision solutions that are not only customised and cost-effective but also work extremely well as soon as they are implemented. A recent development under Nikon’s Digital Manufacturing banner is closer cooperation between IMBU and the corporation’s Digital Solutions Business Unit (DSBU), which has launched a series of optical additive and subtractive manufacturing solutions for processing a wide variety of materials to sub-micron surface finish. www.industry.nikon.com