Products and promotions may differ based on your selected region.

X-ray And CT Metrology Solutions

Unlock New Possibilities with Nikon’s Cutting-Edge X-ray and CT

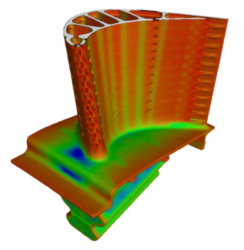

Nikon’s cutting-edge X-ray and CT systems empower customers with powerful 3D imaging for component analysis to meet immediate business needs and uncover new opportunities. Innovative in-house microfocus X-ray sources up to 450 kV enable detailed visualisation from tiny connectors to large castings. Nikon’s X-ray and CT solutions provide the insights and efficiency gains manufacturers seek, and flexible automation supports precise quality control across R&D, failure analysis, and manufacturing. With exceptional scan volume, resolution, and speed paired with unparalleled image quality and repeatability, Nikon’s systems reveal customer parts in new ways.

Large Envelope CT

Nikon’s VOXLS 40 Series offers configurable X-ray and CT systems with large inspection envelopes supporting multiple sources and detectors to suit the most demanding inspection requirements.

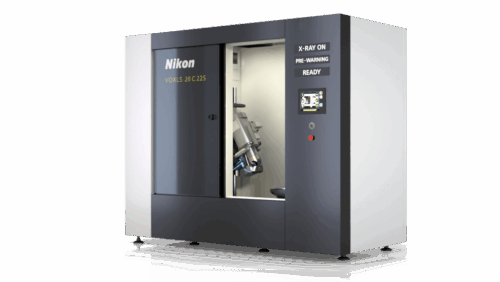

XT H Series

Versatile microfocus CT systems for high-resolution inspection in R&D and failure analysis of components ranging from tiny plastic connectors up to aluminium castings.

X-ray Source Technology

Nikon’s in-house designed and built microfocus sources up to 450 kV that are at the heart of all our CT systems.

Automated Solutions

Various levels of automation to support first article inspection, quality control or 100% inspection in a production environment.