Products and promotions may differ based on your selected region.

VOXLS 20 Series – Compact X-Ray and CT Systems

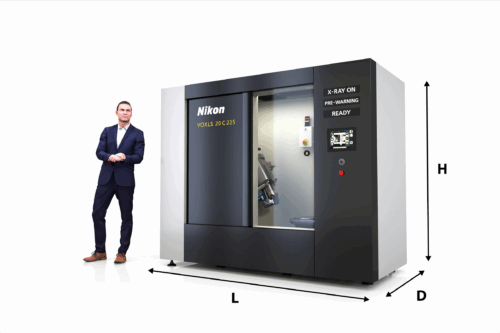

Nikon’s VOXLS 20 Series systems deliver industry-leading CT inspection capability in a space-efficient footprint, paired with scan energies up to 225 kV, making it an ideal solution for a wide range of samples.

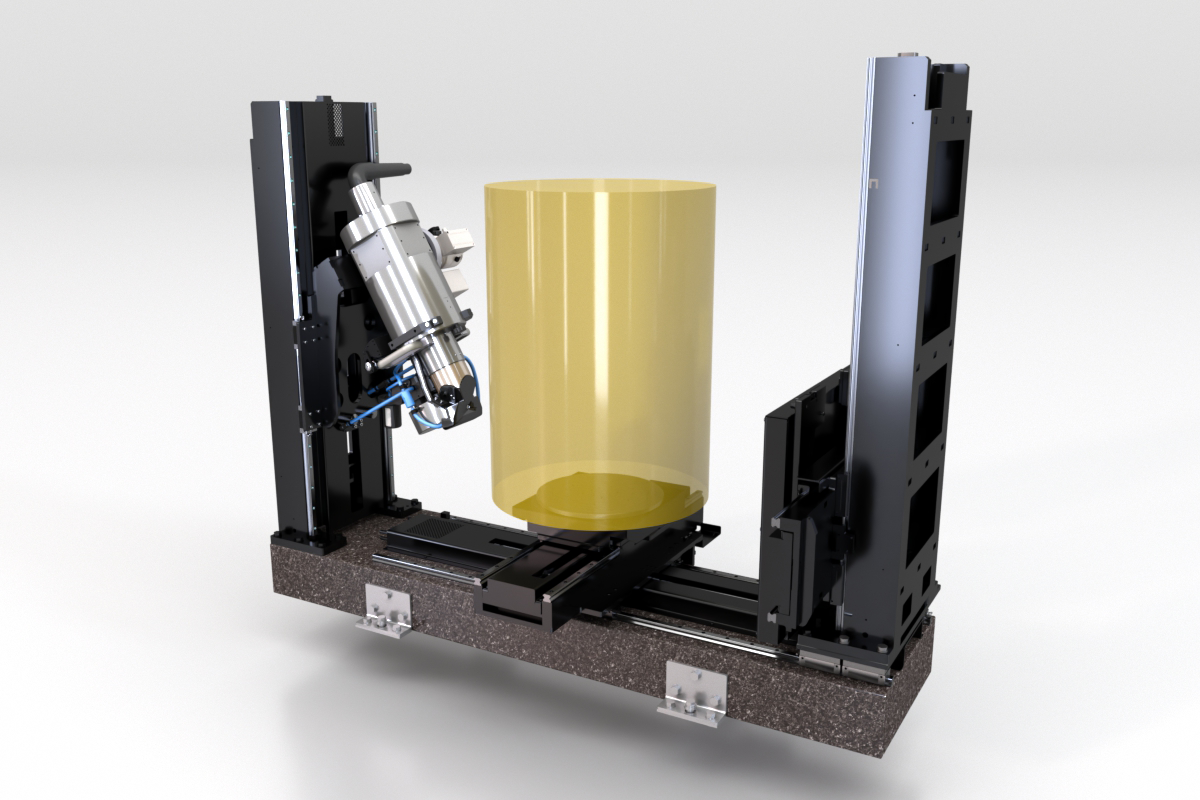

Exceptional performance in a space-efficient design

Versatile

The VOXLS 20 Series of X-ray and CT systems is perfect for quality control laboratories and production environments where space is at a premium. The system is built for precision and reliability through the metrology-grade, granite-based manipulator and rigid steel towers, delivering exceptional X-ray and CT data quality in a compact footprint that fits through a standard double door.

Product Highlights

Versatile

Superior Inspection Envelope

The VOXLS 20 Series offers a best-in-class CT inspection envelope for its size, enabling users to inspect a diverse range of samples within a single system. With Scan Enhancements like X.Tend Helical CT, Offset.CT, and Panel Shift CT, it maximises system utilisation for a rapid return on investment and provides the flexibility to adapt to evolving business needs.

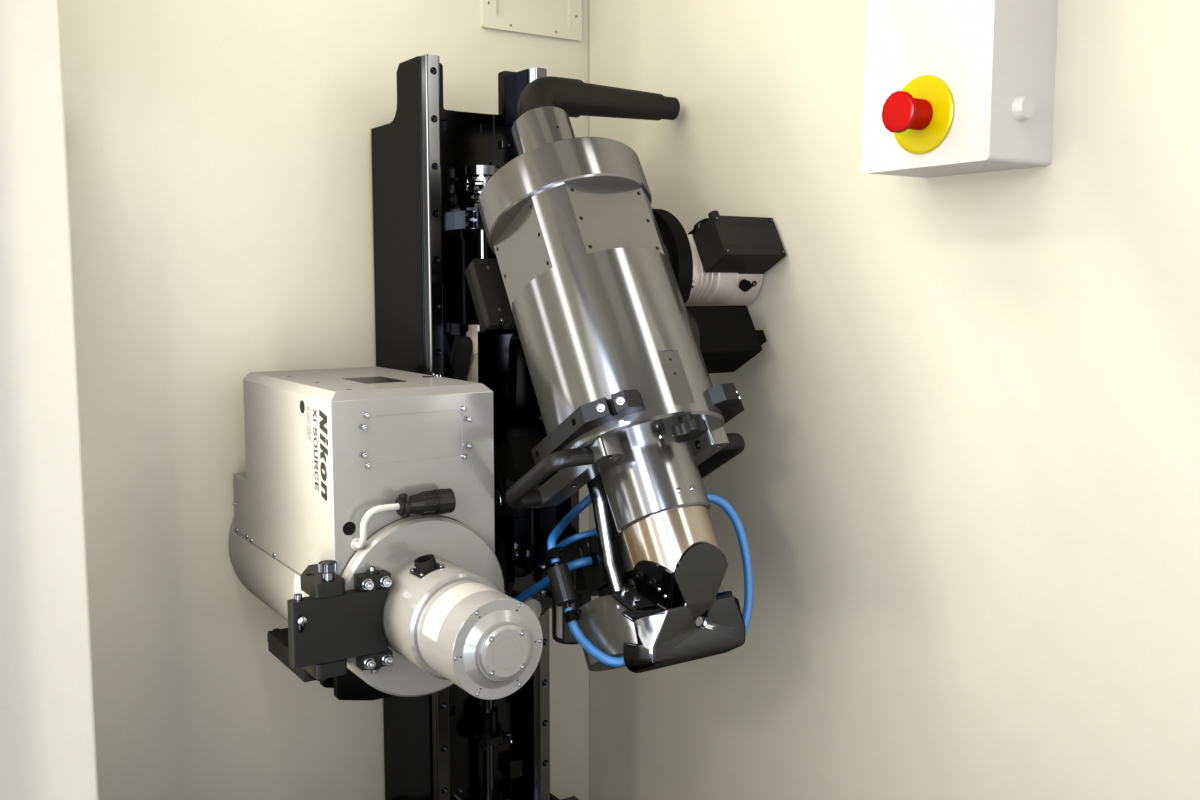

Versatile

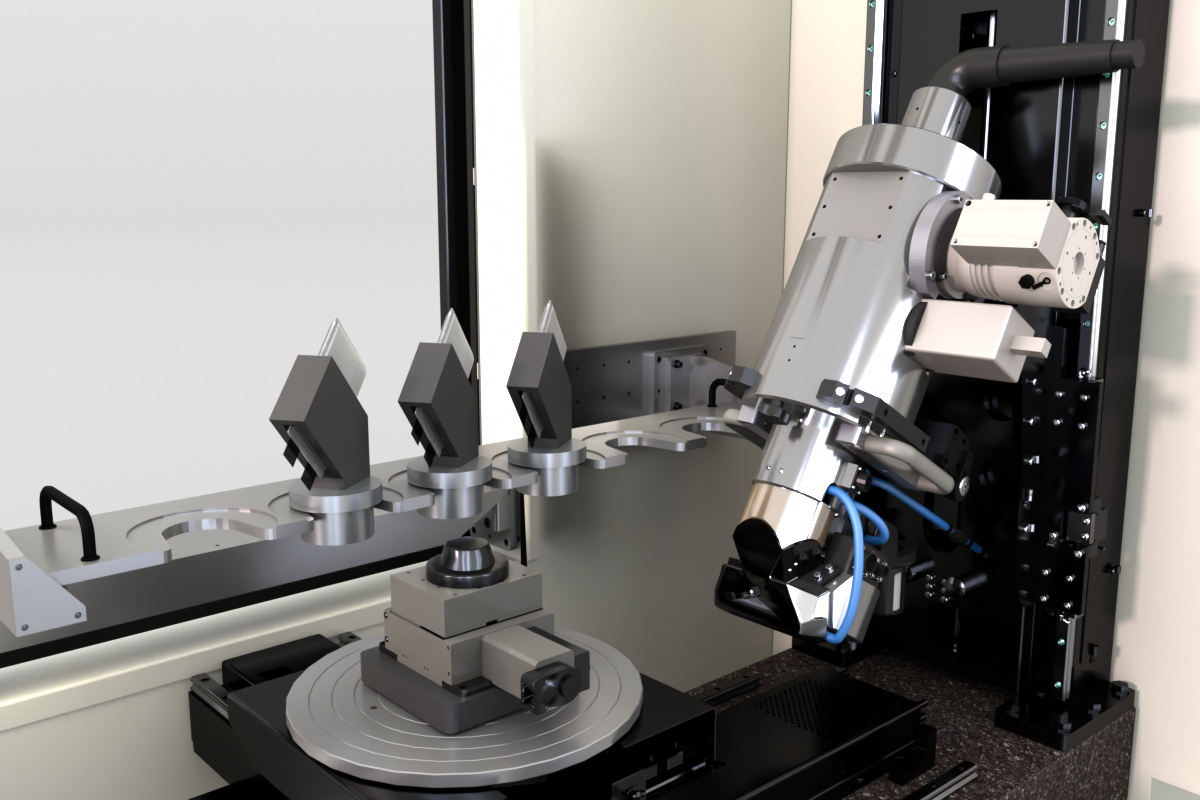

Dual-Source Configuration

Nikon’s VOXLS 20 C 225 offers a motorised dual-source configuration allowing users to select the optimal source for their application. With a simple push of a button, users can quickly switch between the 225 kV reflection target for increased flux and productivity, and the 160 kV transmission target for the best possible resolution.

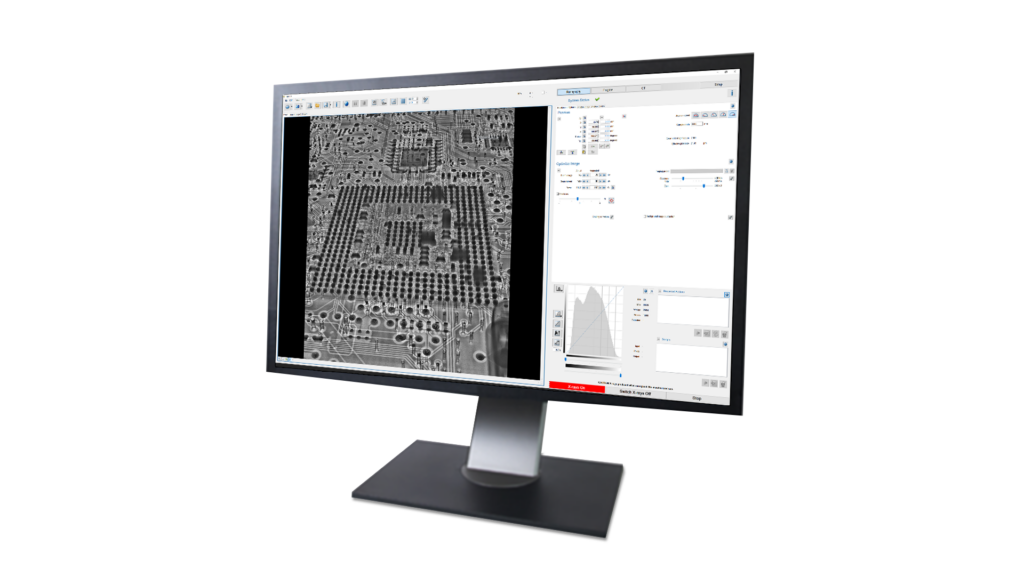

User-Friendly

Source Optimisation

Source Optimisation is a multifunctional innovation used to ensure peak performance of the source filament by streamlining the process of filament replacement, setup and ongoing optimisation. The tool results in improved source performance, longer filament life, and reduces operational stress, allowing users to focus on meeting their productivity and department goals.

User-Friendly

Operator-Focused Design

All VOXLS 20 Series systems prioritise user convenience and efficiency. A large viewing window ensures confident sample positioning, while the motorised door opens in under 4 seconds to minimise wait times and enhance workflow. Features like the Filter Changer and Source Optimisation further simplify operation and maintenance, enabling a highly efficient and satisfying experience.

Premium Data Quality

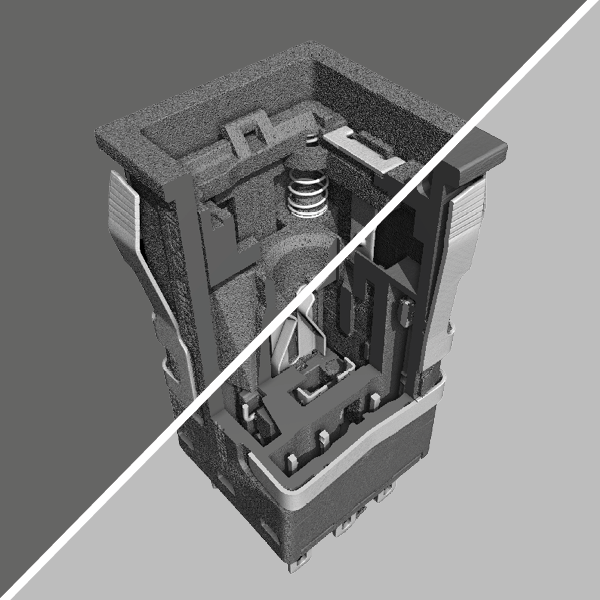

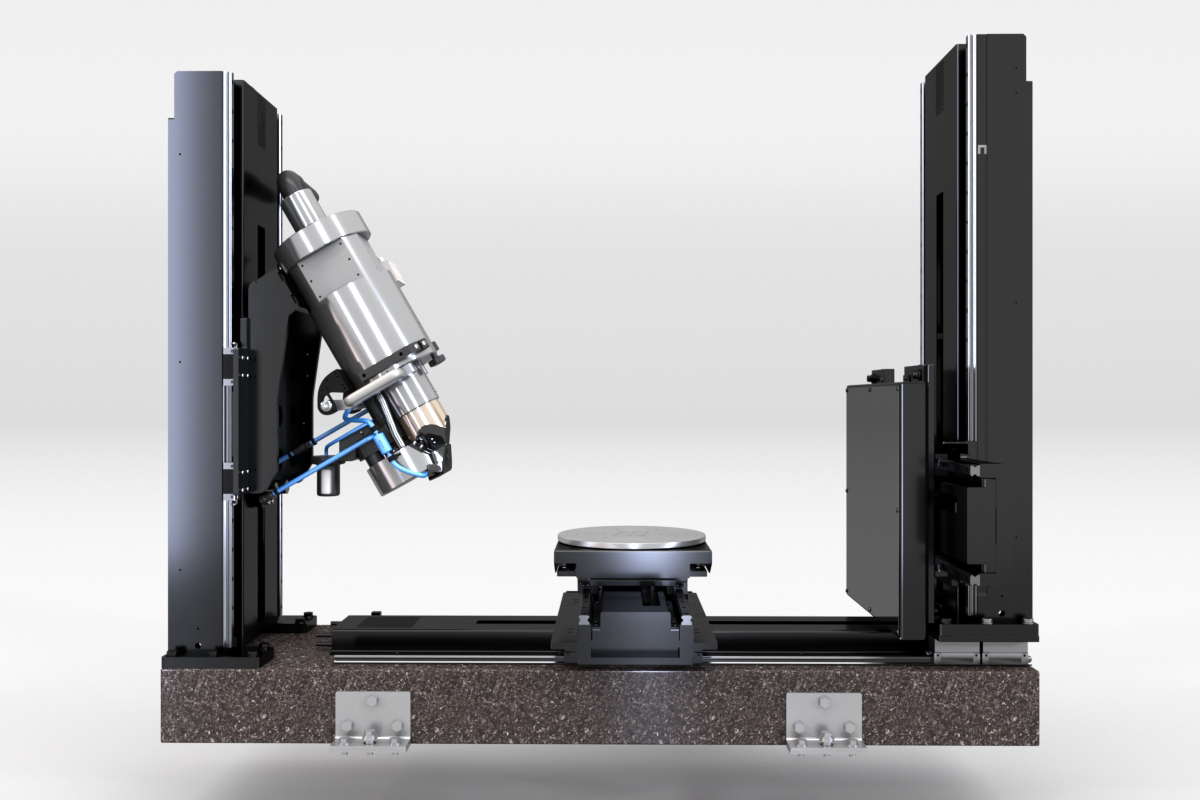

Metrology-Grade Manipulator

At the core of VOXLS 20 Series systems is a metrology-grade, granite-based manipulator coupled with rigid steel towers, and high-precision encoders and motors. The robust construction provides superior mechanical and thermal stability, enabling more accurate, precise, and repeatable data collection. This gives users greater confidence when making product design or quality control decisions.

Productive

Automation Ready

Increase technician efficiency with easy-to-use and operator independent Scan Profiles and Batch Scanning functions. Alternatively, use the Autoloader or robotic loading with Nikon Automation OPC UA interface for autonomous inspection and maximum efficiency in a production environment.

Specifications

| Source | 225 kV Microfocus source with Static or Rotating Reflection Target |

| Optional 160 kV source with Transmission Target | |

| Max Scan Volume | 555 x 759 mm (Ø x H) |

| Max Sample Size | 750 x 1,297 mm (Ø x H) |

| Max Sample Weight | 90 kg central load |

| System Dimensions | 2,451 x 1,173 x 2,018 mm (L x D x H) |

| System Weight | 4,800 kg |

Go Further with Scan Enhancements Features

Expand your scan envelope, improve clarity, increase resolution, and boost productivity with Nikon Scan Enhancements. Combining innovative hardware and software modules, Nikon’s suite of Scan Enhancements pushes the limits beyond traditional X-ray and CT, especially for challenging samples. This provides users with the quality to make confident decisions, the throughput to increase profitability, and the flexibility to adapt to evolving business needs.

Industry Applications

The automotive industry requires inspecting various components, from electrical systems to lightweight structural parts. The VOXLS 20 Series allows the inspection of these diverse components while maintaining a small footprint in automotive manufacturing facilities.

The aerospace industry demands precision and reliability in all components. With its metrology-grade platform, the VOXLS 20 Series enables detailed inspection of critical aerospace parts, from complex turbine blades to intricate electronic systems, ensuring they meet rigorous quality standards.

Academic research requires some of the most diverse scanning applications of all organisations, including fossils, new blends of composites, cutting-edge alloys, plant and animal sciences, and more. The VOXLS 20 Series provides the resolution capabilities and scan enhancement technologies needed to help researchers find the answers they are seeking, all within a compact footprint that fits well in space-constrained university laboratories.

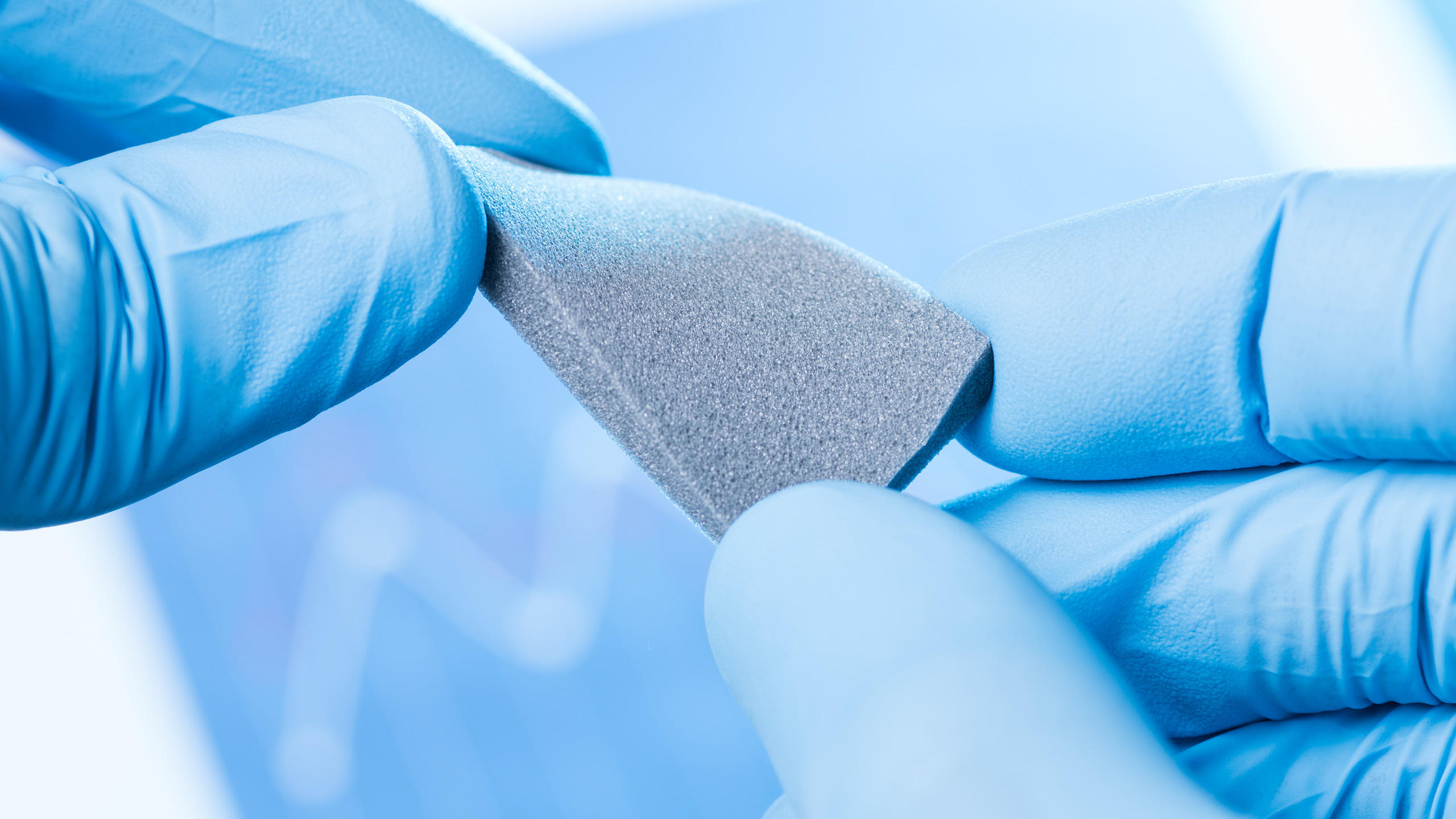

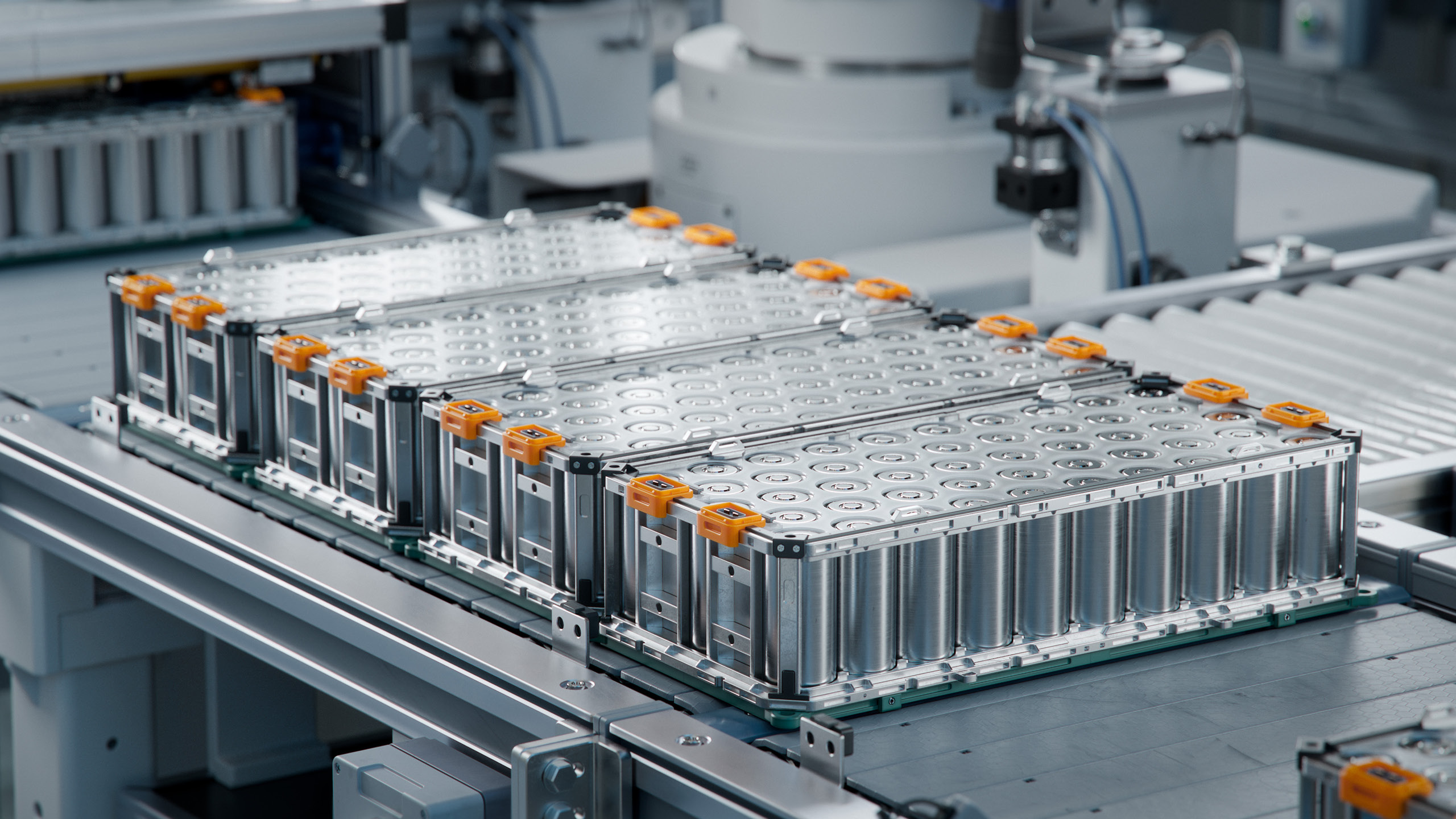

The rapidly innovating EV and electrical storage market has growing demands on battery inspection to ensure their performance and safety, The VOXLS 20 Series is suited to inspect all types of battery cells whether it is in R&D and Failure Analysis or for production quality control.

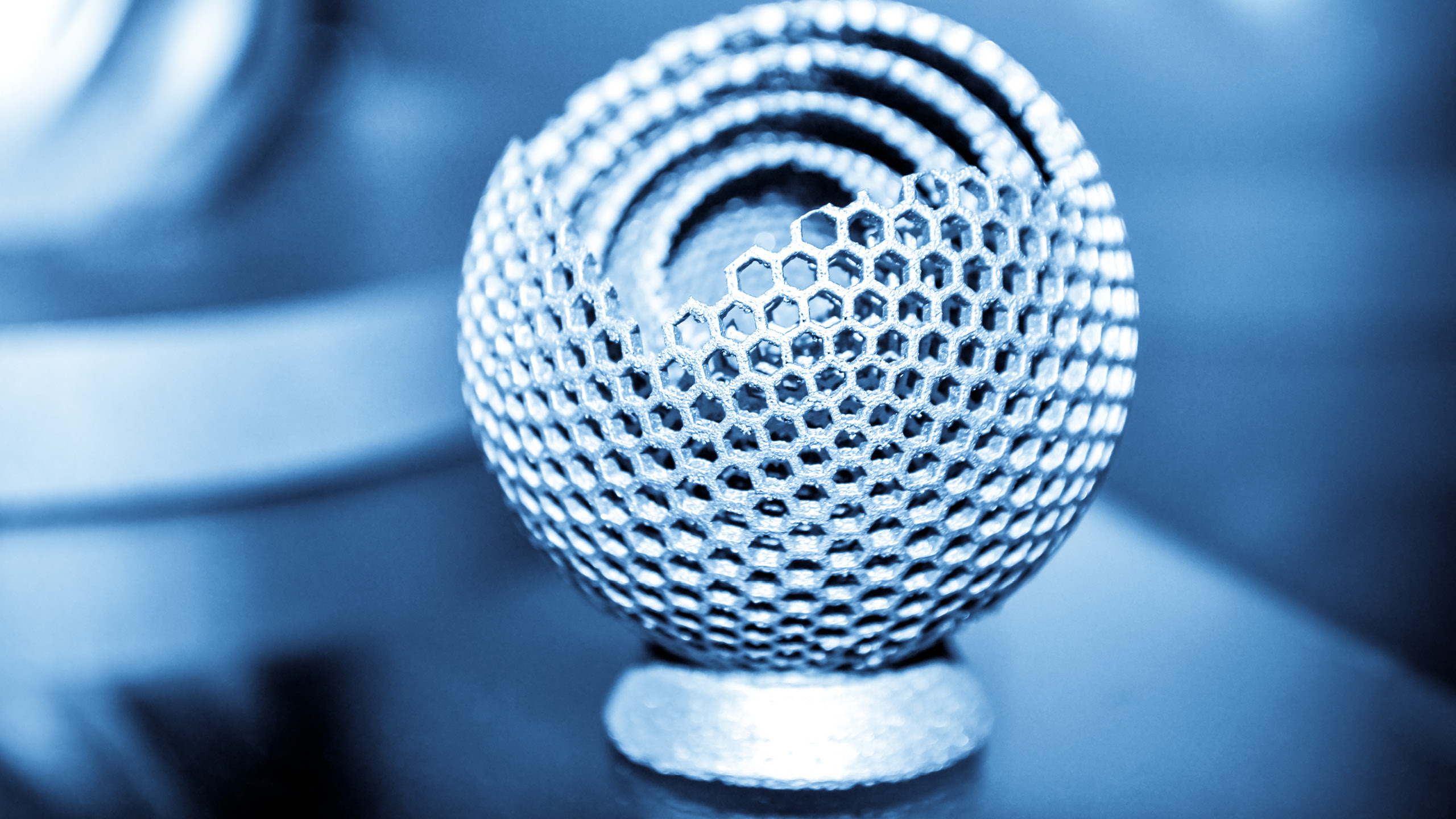

Additive manufacturing has revolutionised prototyping and production across multiple industries. The VOXLS 20 Series offers the perfect solution for inspecting complex geometries, internal structures, and potential defects in 3D-printed parts, ensuring quality control throughout the additive manufacturing process.

From light alloys to high-precision components, manufactured castings are essential across numerous industries. The VOXLS 20 Series is ideally suited for inspecting small-to-medium castings, identifying inclusions, porosity, and shrinkage that could affect performance. Whether examining individual components or small assemblies, the system’s dual-source configuration allows for optimising scans for different materials and densities.

Electronics are widely used, from microchips to multilayer circuit boards. The VOXLS 20 Series provides the resolution to detect defects in BGAs and cracks in bond wires, all while fitting into space-constrained electronics manufacturing environments.

FAQs

The VOXLS 20 Series is designed to offer maximum capability in a more compact footprint, which is ideal for facilities with space constraints. While maintaining the exceptional data quality and metrology-grade platform that Nikon is known for, the VOXLS 20 Series has a smaller physical footprint that allows it to fit through a standard double door, providing greater installation flexibility.

The VOXLS 20 Series is ideal for scanning a wide range of samples. This includes electronics, plastic parts, lightweight metal components, additive manufactured parts, and medical devices. With its dual-source configuration, you can choose between the reflection target for higher productivity due to increased X-ray flux or the transmission target for achieving the best possible resolution depending on your application.

The metrology-grade manipulator provides exceptional stability and precision with its granite base and rigid steel towers. This ensures highly accurate and repeatable sample positioning, directly improving data quality and measurement repeatability. These engineering choices ensure the precision, repeatability, and reliability that the Nikon brand is known for.

Source Optimisation de-skills the process of setting up the filament for optimal performance, simplifies the filament change process, and provides a longer filament lifetime. This reduces maintenance requirements, minimises downtime, and ensures consistent scan quality over time, making the system more user-friendly and cost-effective to operate.

The VOXLS 20 Series is designed as a long-term investment and can adapt to evolving manufacturing needs. It is upgradable and has a range of automated and robotic inspection solutions using Nikon Automation with OPC UA Interface, allowing for future integration into automated production environments as your requirements grow.

Related Products

Scatter Correction CT

Tilted CT

Speak To Us About This Product

If you would like further details on this product or a more in-depth description, our expert team will provide you with additional information and, if required, arrange an on-site visit. Talk to us in detail about your project and our experts will advise you on the best inspection system to meet your requirements. Please fill out the form opposite and we will get in touch with you shortly.