Products and promotions may differ based on your selected region.

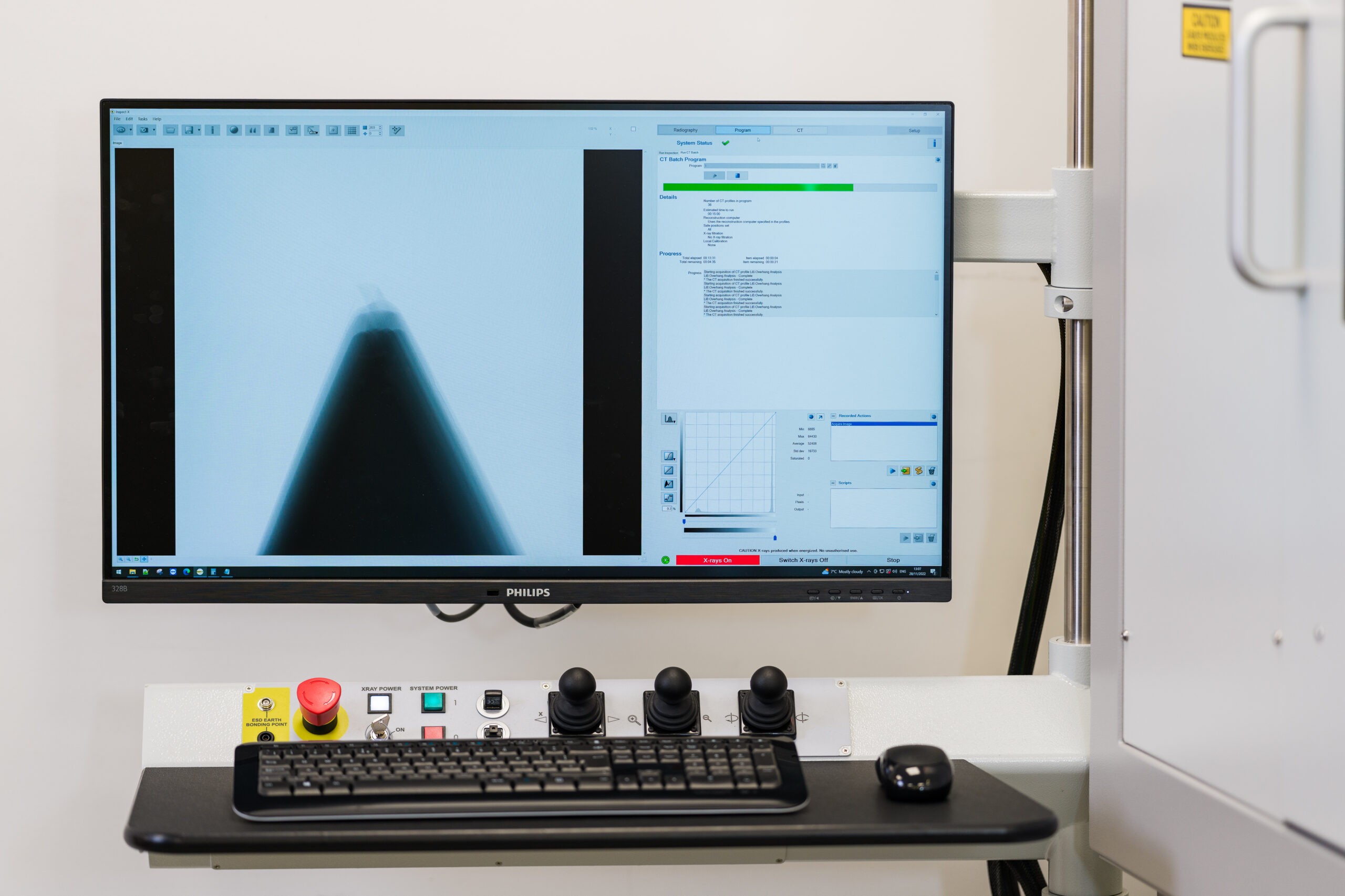

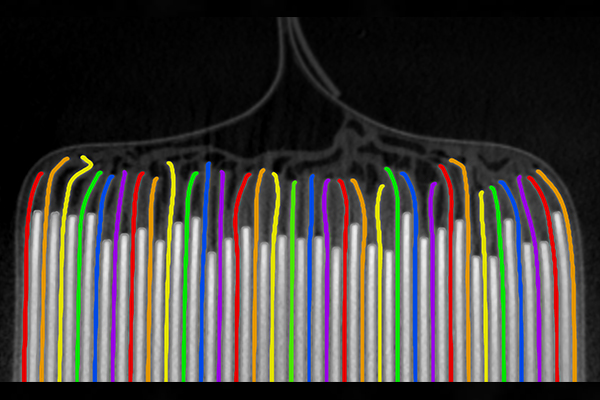

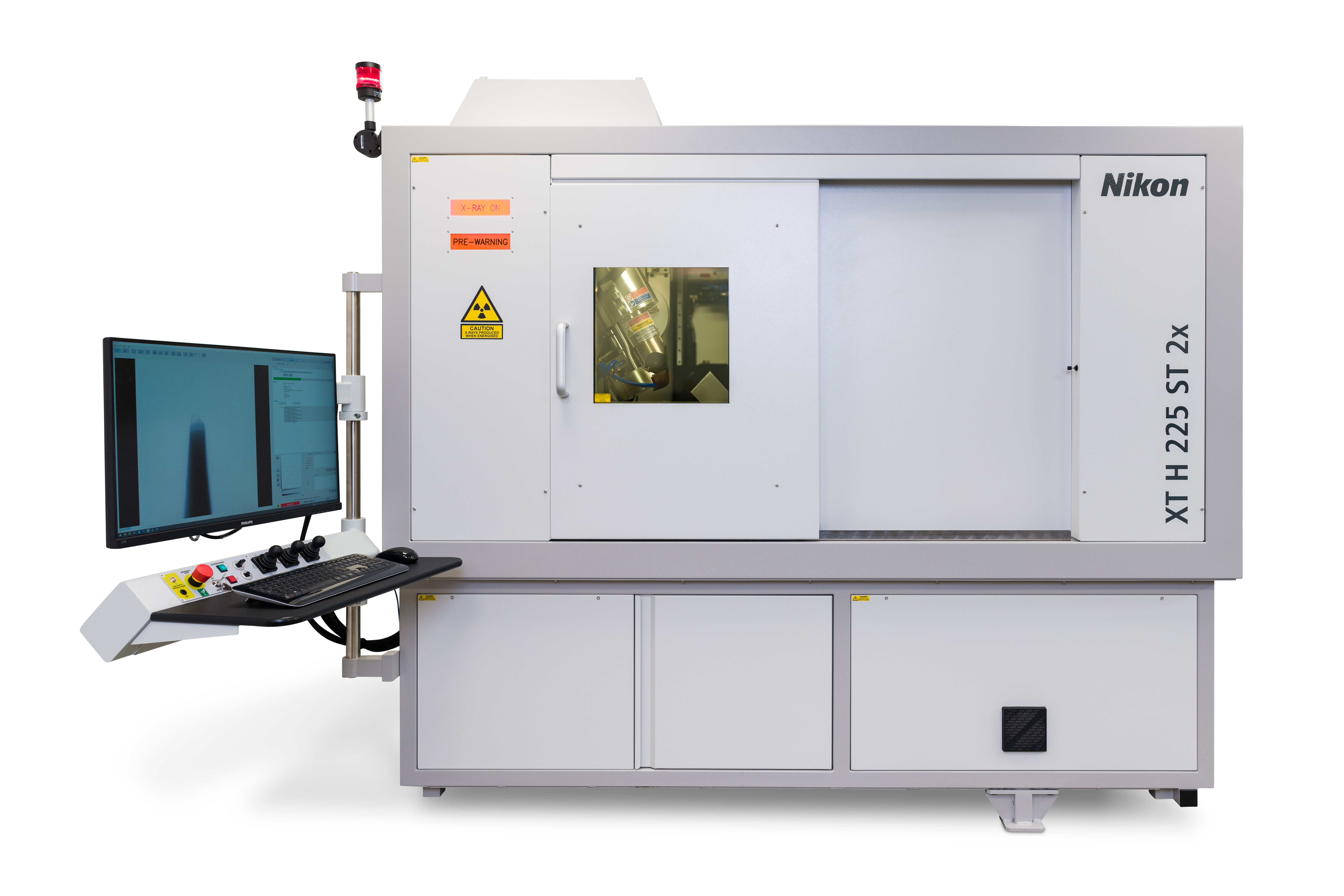

Driving increased reproducibility, automatic analysis gives numerical results from beginning to end – without the need for an operator.

AI analysis technology is tolerant to noise and works reliably, even on high-speed CT datasets.

Machine-readable output for integration with process control systems optimizes the production process.

If you would like further details on this product or a more in-depth description, our expert team will provide you with additional information and, if required, arrange an on-site visit. Talk to us in detail about your project and our experts will advise you on the best inspection system to meet your requirements. Please fill out the form opposite and we will get in touch with you shortly.