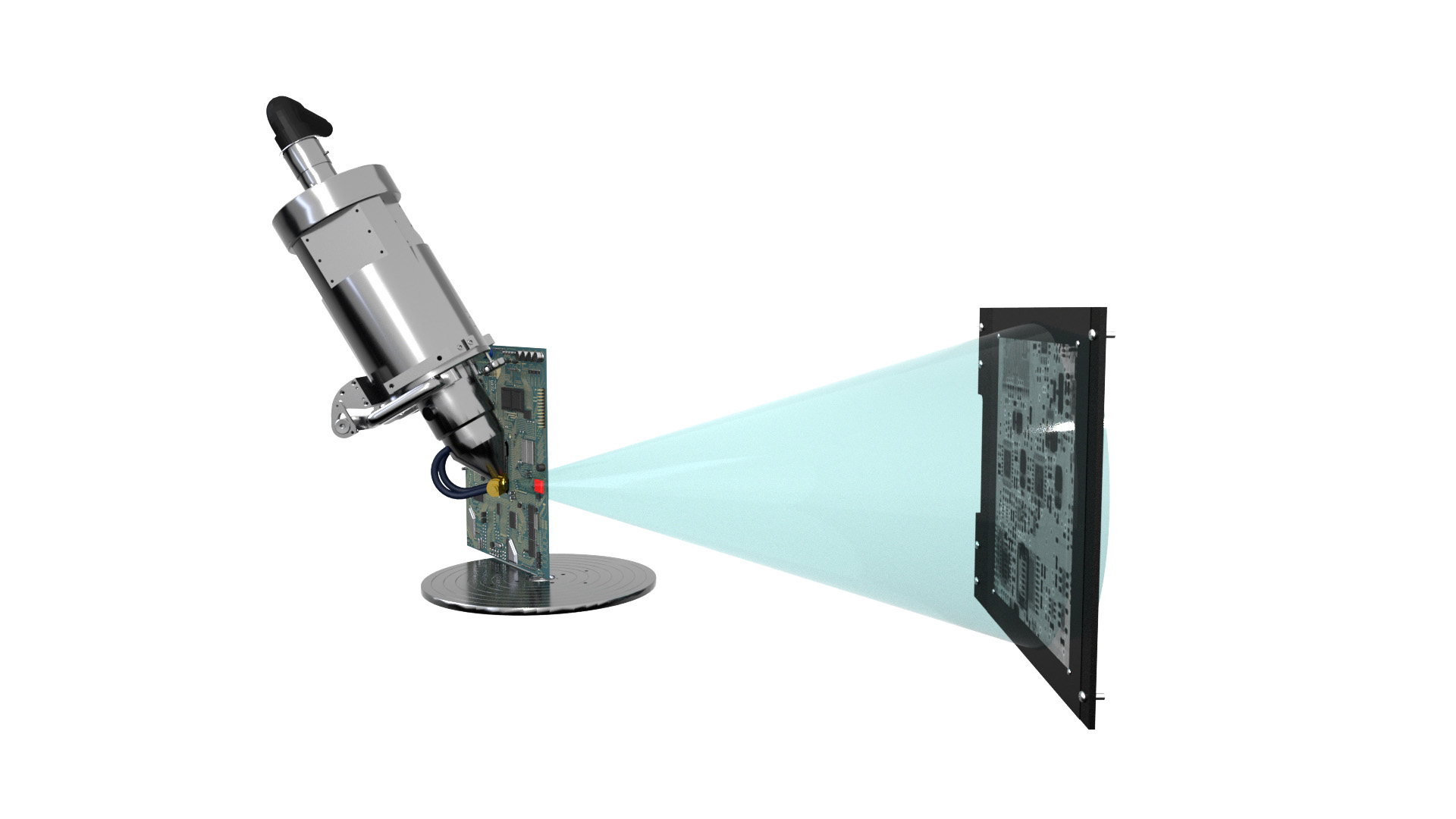

Nikon IMBU (https://industry.nikon.com) has released AI Reconstruction, an innovative 3D computed tomography (CT) reconstruction software solution powered by artificial intelligence that lifts the traditional trade-off between scan speed and image quality.

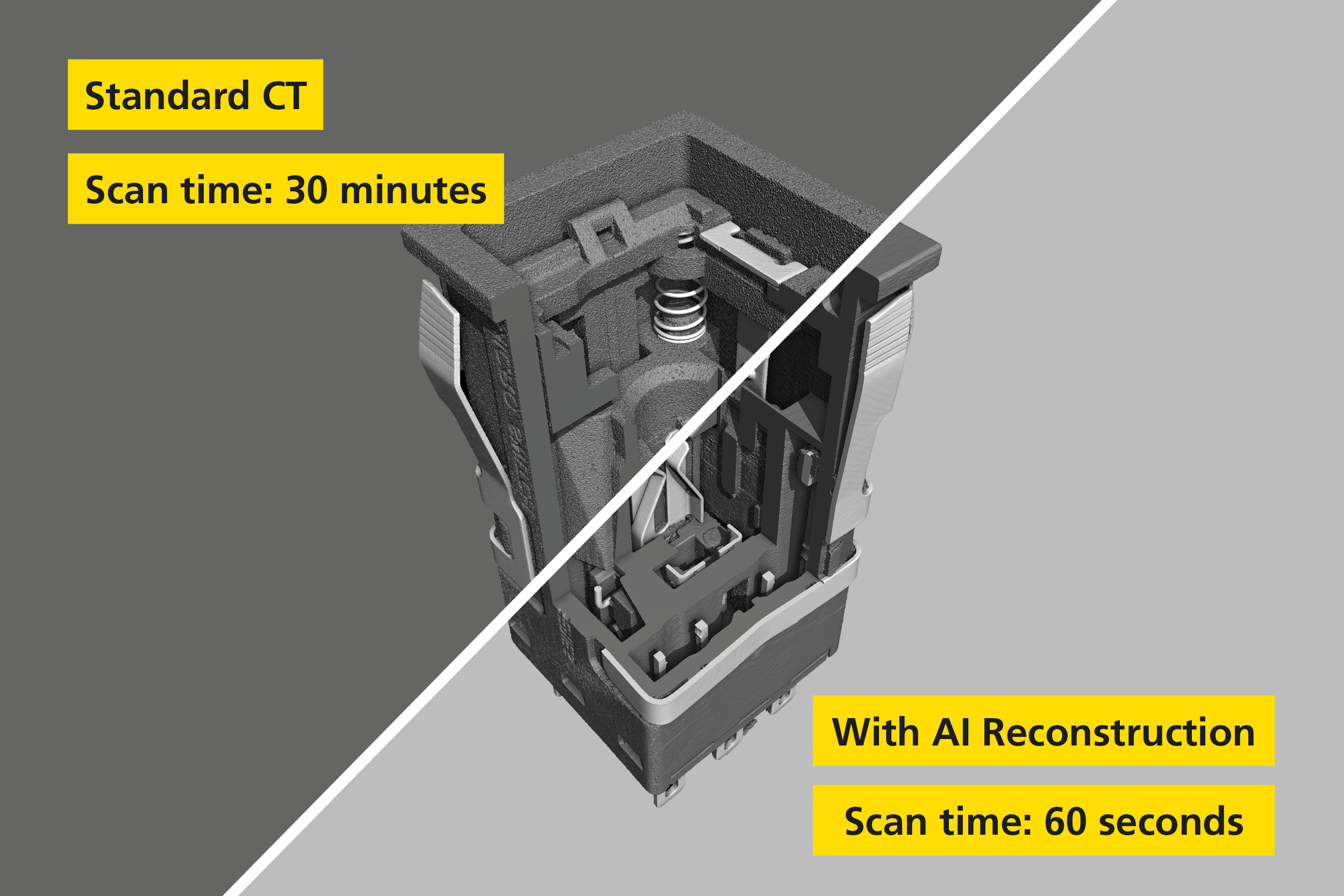

By applying Deep Learning techniques to enhance image quality, Nikon’s breakthrough technology enables rapid results and superior analysis. Traditionally, CT users have had to pick between fast, lower-quality scans or slow, higher-quality scans. If scans are quick, important details can be missed. If scans are slow, fewer items can be scanned.

AI Reconstruction lifts these limits through AI enhancement tailored to individual customer needs by Nikon’s Applications Engineering team. The Deep Learning modelling underpinning AI Reconstruction is trained to distinguish relevant information from the scan artifacts to effectively filter noise and improve clarity.

“Nikon’s latest breakthrough in AI-enhanced 3D reconstruction represents a fundamental change for industrial computed tomography,” says Chris Price, Product Manager with Nikon for X-ray & CT Systems. “By lifting the speed-quality trade-off, AI Reconstruction provides both rapid results and superior image clarity, unlocking a new level of scan flexibility for all users.

“This technology leap helps testing and quality teams enhance throughput and precision like never before — the dramatically sharper image quality reveals minute product flaws that used to require painstaking scans, while the faster scan speeds let users reliably analyse many more units per day.”

Examples of where this technology will demonstrate a profound impact include the automotive, aerospace and manufacturing sectors, as well as the medical device industry. In these sectors and others, meticulous quality control via precise metrology is essential for product safety.

Through rigorous trials, Nikon’s breakthrough technology has been validated to provide dependable performance. It offers flexible integration with leading analysis packages for reliable inspection of the most challenging component geometries.

AI Reconstruction has been designed to comply with the European Union’s Ethics Guidelines for Trustworthy Artificial Intelligence. These guidelines propose seven key requirements for trustworthy AI systems: human agency and oversight, technical robustness and safety, privacy and data governance, transparency, diversity, non-discrimination and fairness, societal and environmental well-being, and accountability.

Nikon’s new AI solution is built on the same technology as Nikon’s LiB.Overhang Analysis, released in 2023. Although they both use Deep Learning AI, their goals are different. LiB.Overhang Analysis is a dedicated analysis solution that enables fast, precise, and consistent CT inspection and analysis of anode overhang in lithium-ion batteries (LiBs) during mass production.

By automatically analysing the 3D CT scan data using AI, LiB.Overhang Analysis can accurately measure the critical dimensions of anode overhang regions in LiB cells to ensure they are within the required tolerances for optimal battery performance and safety.

“AI Reconstruction has a much broader range of applications,” says Price. “Rather than performing analysis, it improves image quality so that scans can be easily analysed using industry-standard software. That means many more sectors can benefit, creating unprecedented opportunities for improvement in areas including castings, additive manufacturing, as well as academia, research and many more.”

Nikon’s AI Reconstruction is provided as a tailored service drawing on the company’s expertise in meeting specific customer needs. An experienced Nikon Applications Engineer partners directly with each client to train an accurate model using samples from a target workflow.

AI Reconstruction’s launch will see Nikon focus on LiB cell production, where the company is already a leading partner for many manufacturers.

“As volumes grow to meet the demands of next-generation transport, manufacturers increasingly require automated quality control to match factory speeds,” says Price. “Nikon intends to solidify its position on the lithium-ion battery assembly line by providing AI augmentation for boosted evaluation productivity.”

Nikon is already proactively contacting existing customers to explain AI Reconstruction’s benefits. New customers should contact their local Nikon Metrology representative to arrange an introductory call and in-person demo.

About Nikon Industrial Metrology

Nikon provides a variety of products, services, and solutions worldwide, based on advanced opto-electronics and precision technologies cultivated during the company’s more than 100 years of history. The group continues to create new values that contribute to improvement of quality of life and manufacturing in a wide variety of forms. Nikon’s Industrial Metrology Business Unit (IMBU) delivers integrated, optimised, ultra-high precision solutions that are not only customised and cost-effective but also work extremely well as soon as they are implemented. A recent development under Nikon’s Digital Manufacturing banner is closer cooperation between IMBU and the corporation’s Digital Solutions Business Unit (DSBU), which has launched a series of optical additive and subtractive manufacturing solutions for processing a wide variety of materials to sub-micron surface finish. www.industry.nikon.com

On behalf of:

Nikon Metrology Europe EV

Interleuvenlaan 86, B-3001 Leuven, Belgium.

Contact: Mona Noujeim, X-ray Marketing Manager Europe

Tel: +32 16 74 01 01

Email: [email protected]

Web: www.industry.nikon.com

Distribution:

4marcom + PR!

Siedlerstraße 33

D-85716 Unterschleißheim

Tél : +49-89-37002940

Contact : Theo Drechsel

Email: [email protected]

Web: www.4marcompr.de