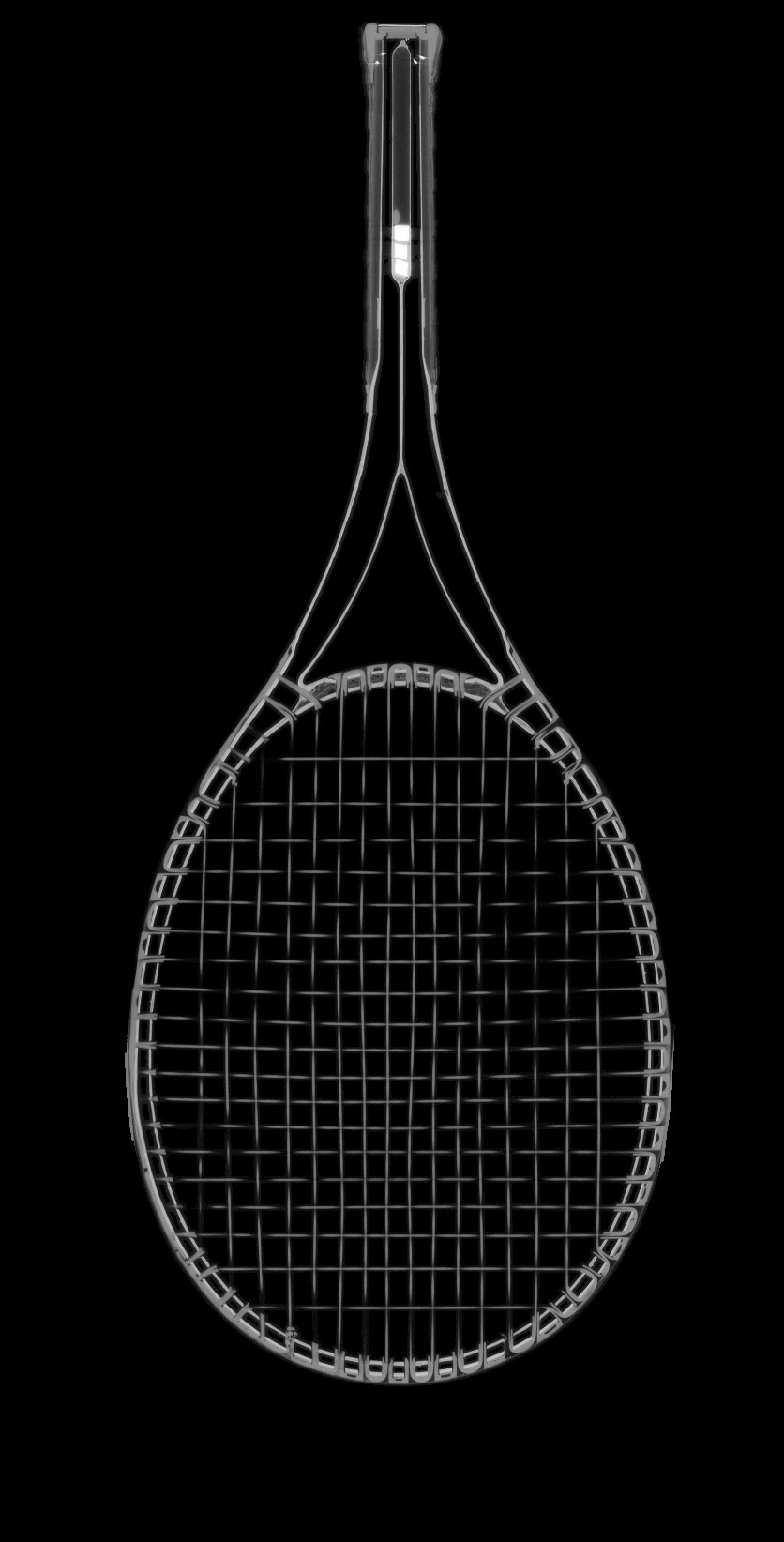

The oldest and most prestigious tennis tournament in the world took place this month: Wimbledon. Established in 1877, it has grown from a modest gentlemen’s singles championship to an internationally renowned event held annually in July. This year, the Wimbledon Championships once again captivated audiences with its impeccable grass courts and unique atmosphere. To celebrate this key tournament, Xinyang Hao and Nicolas Savaete, X-ray CT Application Engineers, have scanned a tennis racket kindly provided by Ucar Hakan, a Nikon engineer.

The tennis racket, an essential piece of equipment in the game, has undergone significant changes in materials and design over the decades. The earliest racket were made of wood, typically ash or maple, providing a solid but heavy and less responsive frame. In the 1960s, the introduction of metal rackets, particularly those made from steel and aluminium, marked a significant shift. These materials offered increased durability and a lighter frame, allowing players to generate more power and speed.

However, the development of composite materials, such as graphite and carbon fibre, revolutionised the game. These materials combined lightweight with exceptional strength and flexibility, enabling players to hit the ball with greater power and control. The shift to graphite-composite rackets in the 1980s allowed for larger head sizes and wider sweet spots, enhancing performance and reducing the risk of injury.

Today, tennis rackets are typically made from a blend of graphite, carbon fibre, and other high-tech materials. Manufacturers continually innovate, incorporating technologies like nanomaterials and shock-absorbing polymers to improve racket performance. These advancements allow players to customise their rackets based on their playing style, whether they prioritise power, control or a balance of both.

The weighted part of the tennis racket grip, often referred to as the “handle weight” or “butt cap weight,” serves several purposes:

- Balance Adjustment: Adding weight to the handle shifts the racket’s balance toward the handle, making it more “head-light.” This can increase manoeuvrability and make it easier to swing the racket quickly, especially useful for volleys and quick reactions at the net.

- Customising Feel: Players often adjust the weight distribution of their rackets to match their personal preferences. A more head-light racket can feel more comfortable and reduce the strain on the arm and wrist, which can be important for preventing injuries.

- Stability and Control: Adding weight to the handle can increase the racket’s overall stability, helping players maintain control during powerful shots. It can also reduce vibrations, providing a more solid feel upon impact with the ball.

Currently, tournament rackets weigh from 310 to 325 grams, but professional players have very specific custom-made models. For example, Djokovic’s current racket weighs over 350 grams.

The racket strings also play a crucial role. Natural gut strings, made from cow intestine, were once the gold standard for their excellent elasticity and feel. Many professional players prefer them, but they are more expensive and less durable.

However, synthetic strings, such as nylon and polyester, have become more popular due to their durability and versatility. Combining different materials, hybrid stringing is now expected to optimize performance characteristics like spin and power.

Each type of string material has its advantages and disadvantages, and the choice often depends on the player’s level, playing style, and personal preference.

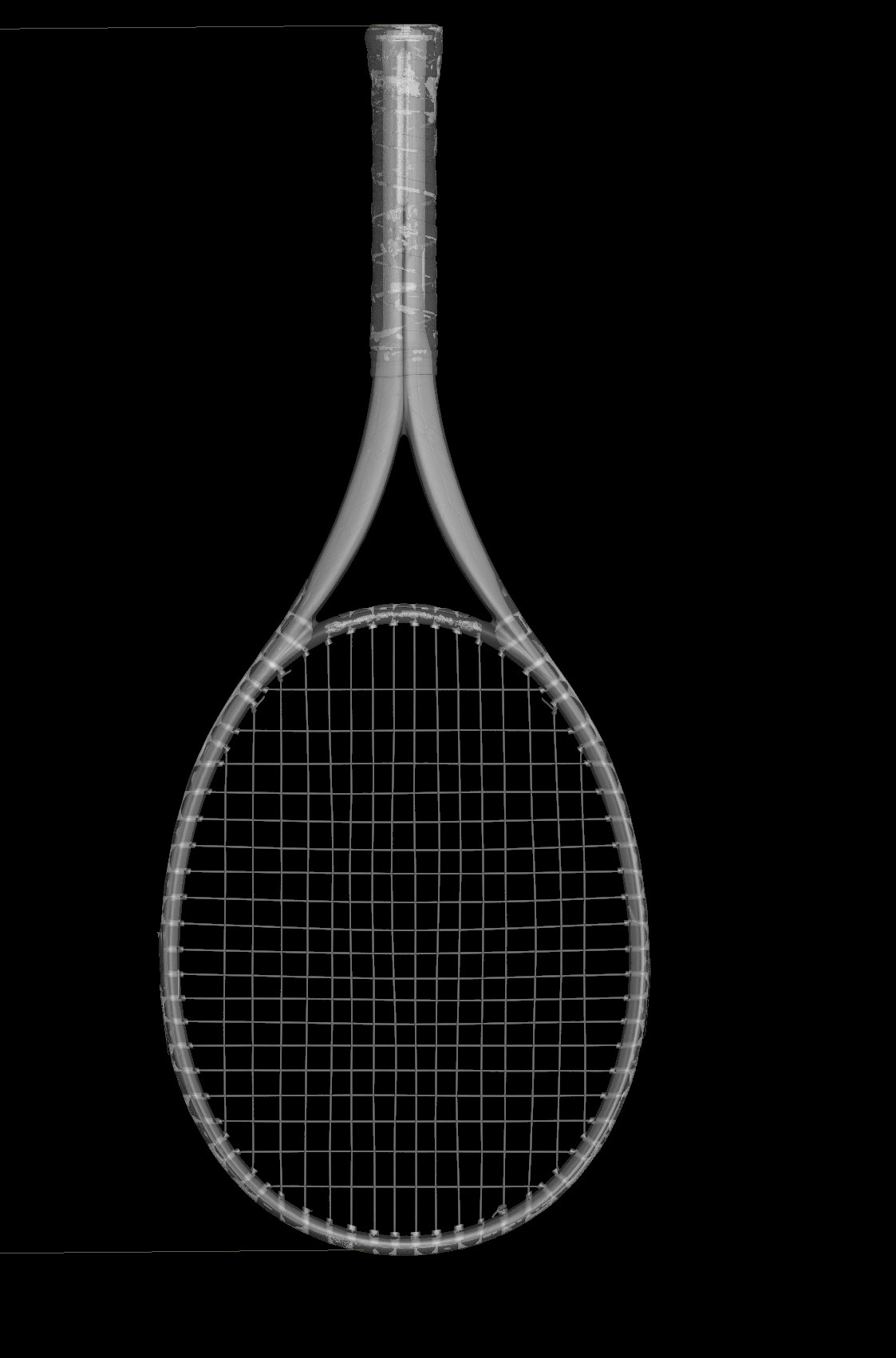

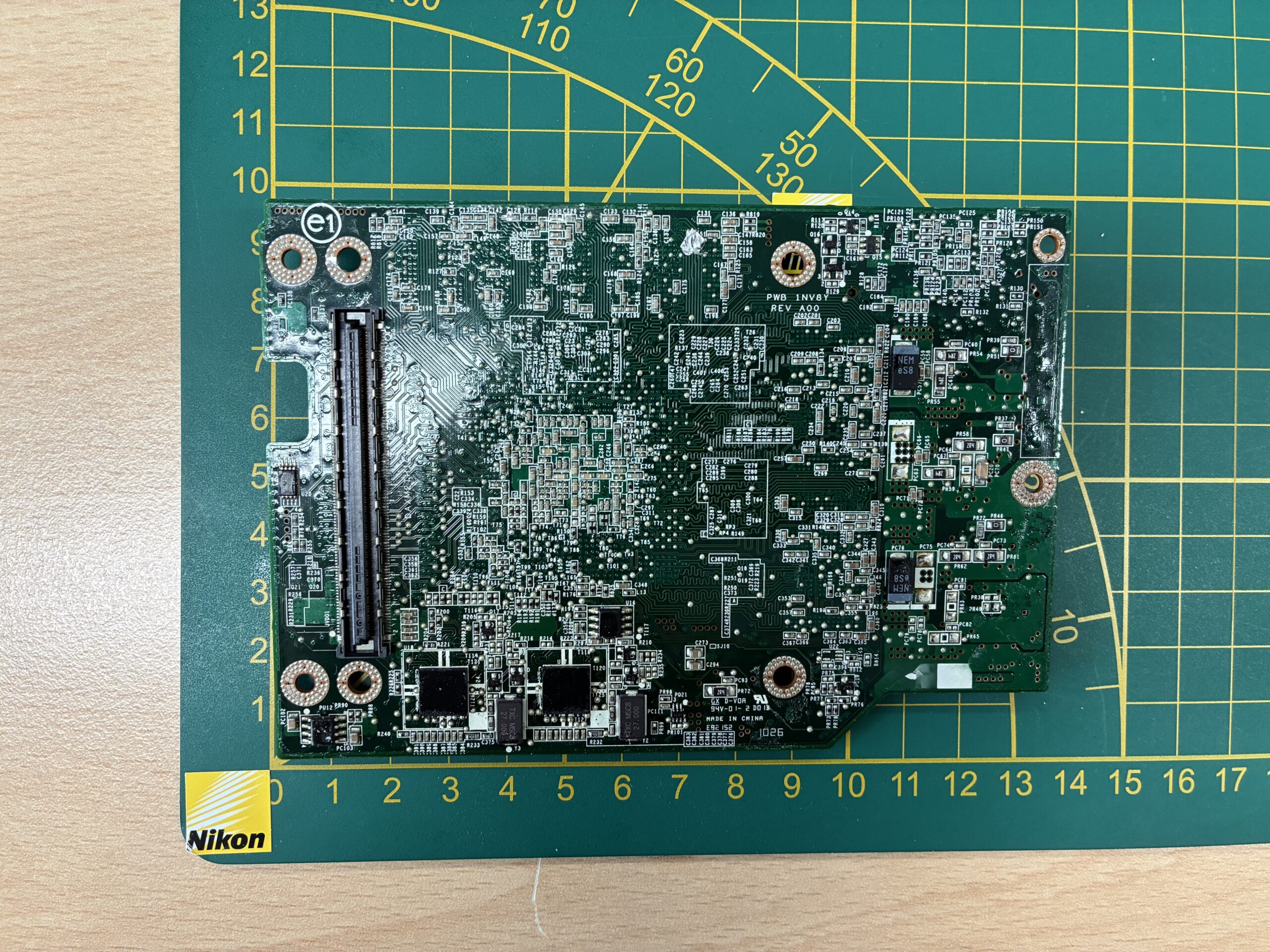

This X-ray CT scan of the tennis racket was acquired using Nikon’s helical acquisition algorithm (X.Tend) at a combined X-ray power of 360 Watts and a voxel resolution of 193 µm, using a Nikon Large Envelope System, C2 . This system has up to three different X-ray sources and dual detectors . This scan was performed using the 225 kV Rotating.Target 2.0 option coupled with a Varex XRD 4343N flat panel detector.

For this scan, the detector acquired 4300 projections (individual radiographs) at an exposure time of 2000 ms, resulting in a total scan time of 2 hours and 40 minutes. The X-ray CT data was reconstructed using an exact helical reconstruction algorithm in Nikon CT Pro 3D and rendered in Volume Graphics Studio Max 2023.4.

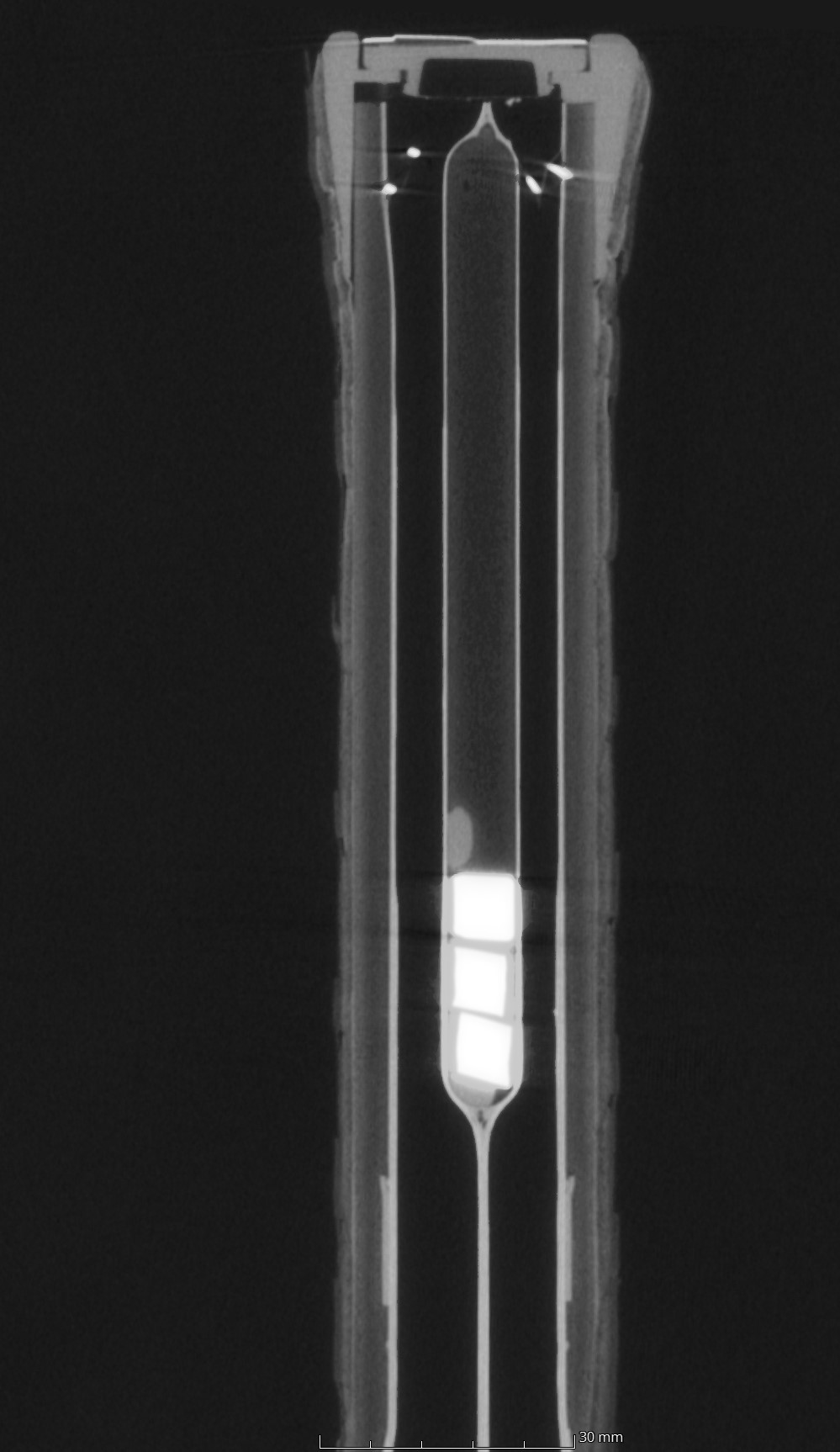

The racket scanned measures 662mm in length, a little shorter than the standard 27-inch (68.5mm) rackets. From the slice through the middle of the grip, we can see that a few metal blocks were glued inside to balance the racket’s weight.

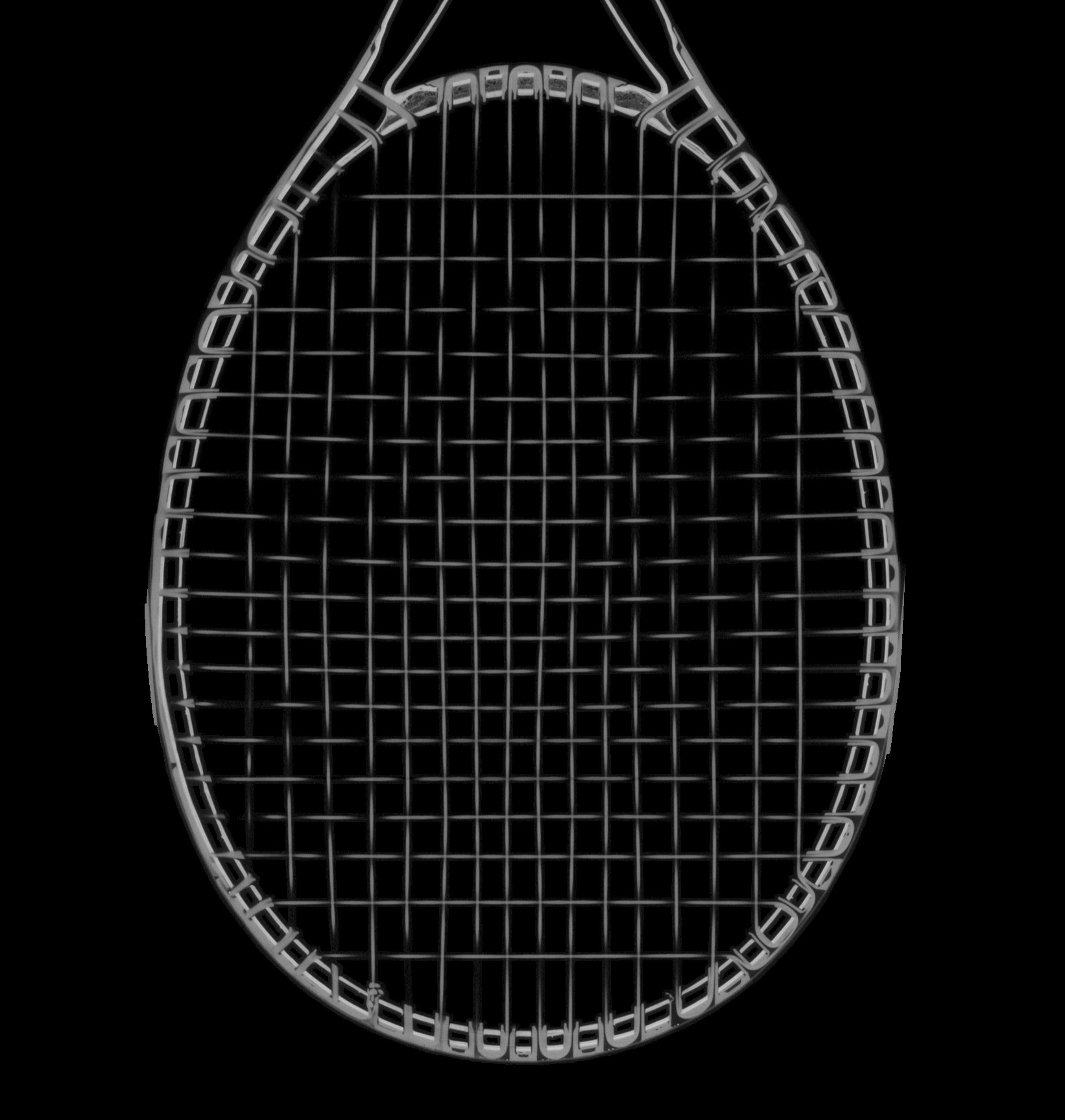

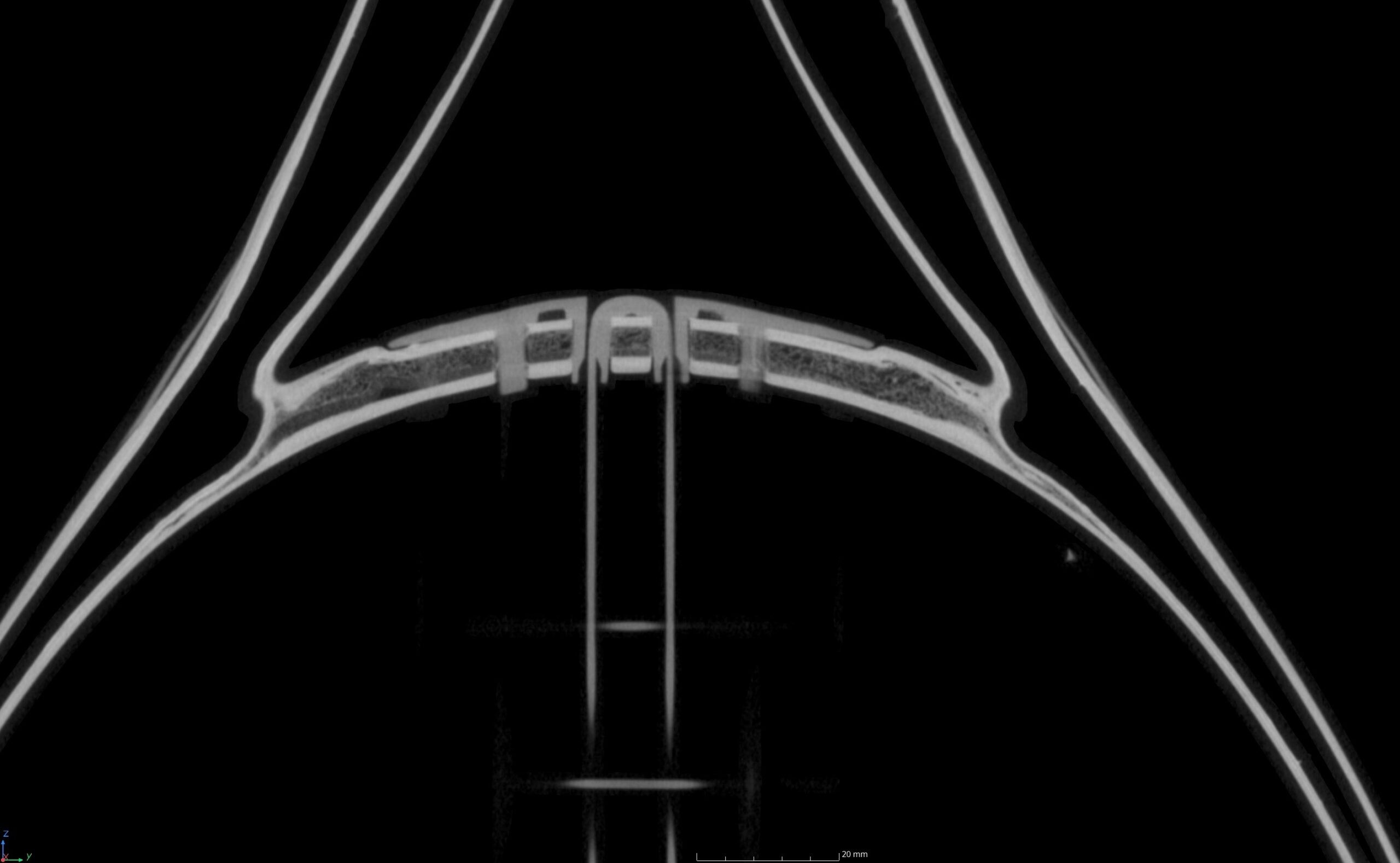

A close-up of the racket frame shows how the strings are attached inside.

The frame of the racket is hollow inside to reduce the weight. The grey values of the scan also show that the frame and the strings of the racket are made from a relatively light material, likely graphite, to further reduce the weight.

Thanks to X-ray CT, we can see the internal structure of the grip as well as on the frame part located just above it. This part of the racket seems to be full of a composite material (likely some resin) to reinforce the structure and dampen the vibrations when hitting the ball.