X-ray CT scans examining charcoal.

This summer, you probably enjoyed some barbecue grilling and used charcoal as a cooking fuel.

Charcoal is a very familiar fuel because it’s frequently used in barbecue cooking. Charcoal is wood transformed during a carbonisation process using high heat and low oxygen. This process is called pyrolysis and eliminates the liquefiable and gasifiable fractions of the wood (which typically makes wood burn fast and with flames). The resulting charcoal then only contains carbon and minerals.

Today, thanks to the industrial production of charcoal in large ovens, we can recover 25 kg of charcoal from 100 kg of wood.

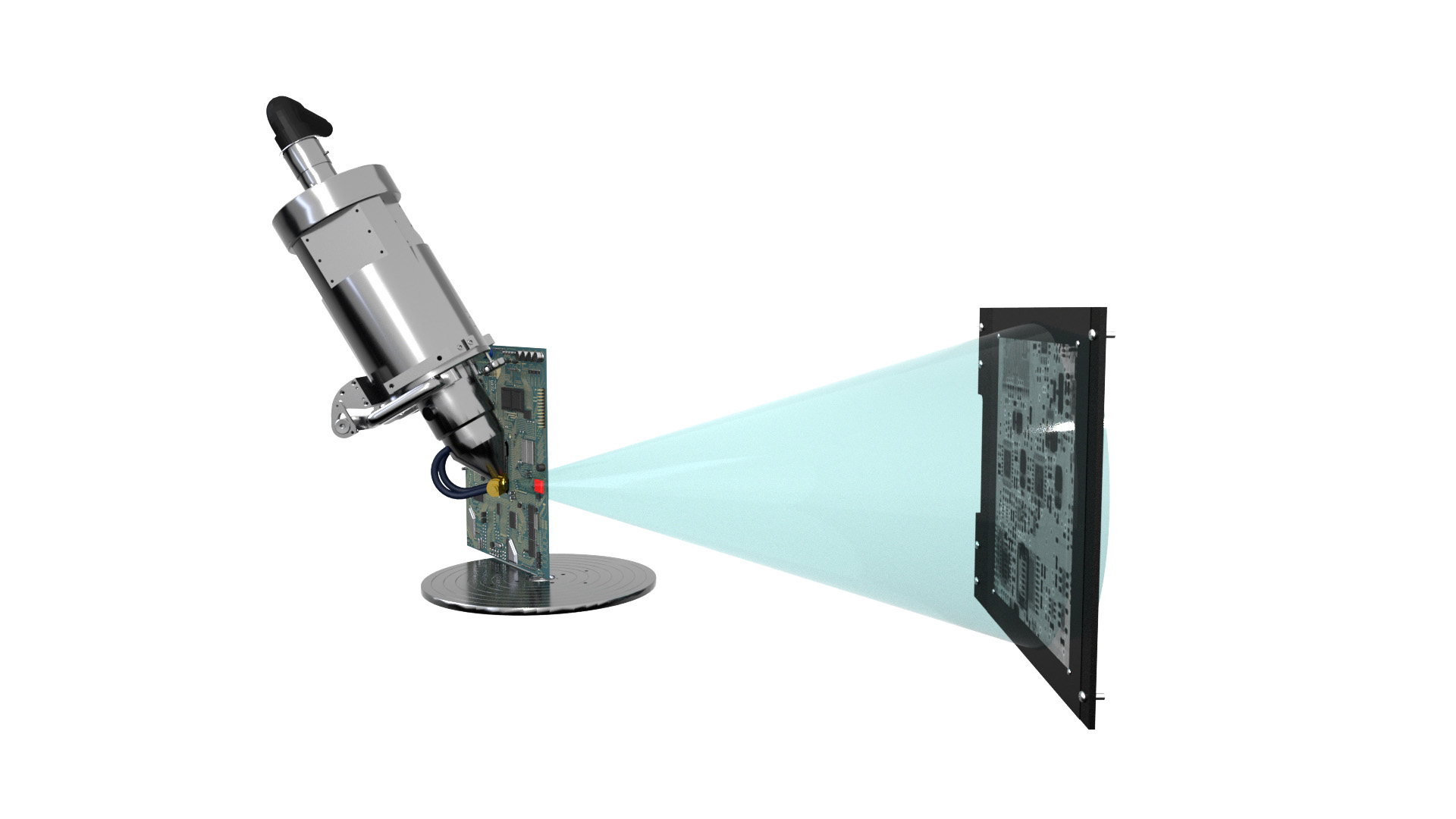

This month we have scanned a piece of charcoal with the XT H 225. X-ray CT enables us to non-destructively inspect its internal structure before and after the burning process.

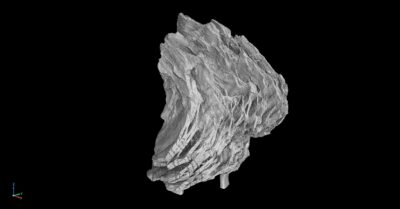

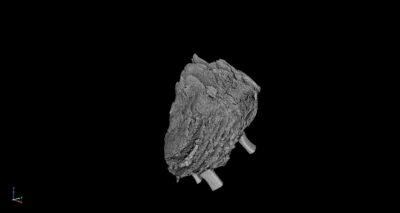

Scan 1: Pre vs Post-burn

The images above show a piece of charcoal we scanned at low resolution, before and after being burnt. For this scan, the detector captured 3925 projections (2 frames per projection) at an exposure time of 2829 ms. As we were aiming for minimum noise, the total scan time was 6 hours. However, with a fully configurable number of projections, our scans can take as little as 1 minute.

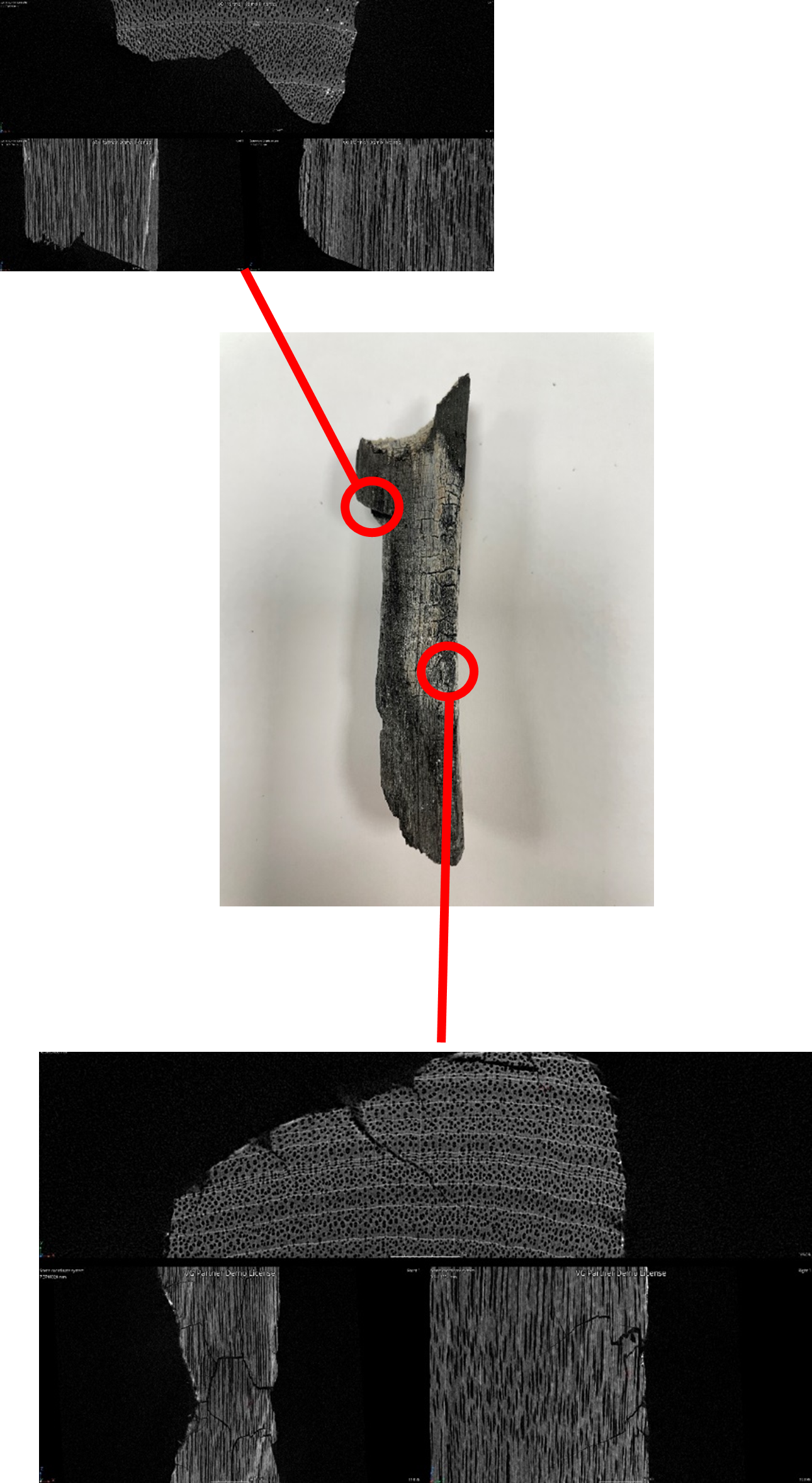

Sample 2: Post-burn

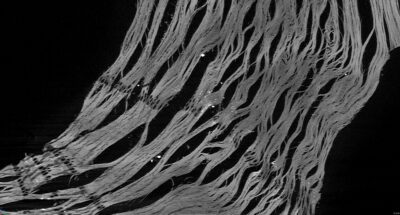

We scanned a second sample at a higher resolution, focusing on two regions. One is an unburnt section where you can see the undamaged layers and another section where the heat has produced cracks.

The detector captured 10648 projections at an exposure time of 708 ms, resulting in a total scan time of 2 hours. We scanned the charcoal with 11 µm resolution. We acquired this X-ray CT scan using Nikon’s helical acquisition algorithm (X.Tend) at a combined X-ray power of 10 W and a voxel resolution of 11 µm, using a Nikon XT H 225.

X.Tend Helical CT is a fantastic and essential tool that enables us to inspect certain parts much easier than using circular CT. Rather than having to do multiple normal circular CT scans and go through the process of stitching the individual scans together (which can be very time-consuming), we perform a single X.Tend scan. This avoids any complications with the field of view or cone beam related issues and we can get the final CT data quicker.