Miklos Kallai is Business Unit Manager at the Gyor, Hungary subsidiary of E-Tronics (www.e-tronics.hu), a provider of top quality and often bespoke production solutions. Founded in Galway in 1993, the Irish headquarters specialises in serving the medical device manufacturing industry, a sector in which the country is particularly strong. In contrast, the Gyor operation focuses on the electronics and automotive industries, while the other subsidiary, in Brno, Czech Republic, concentrates on the medical and electronics sectors.

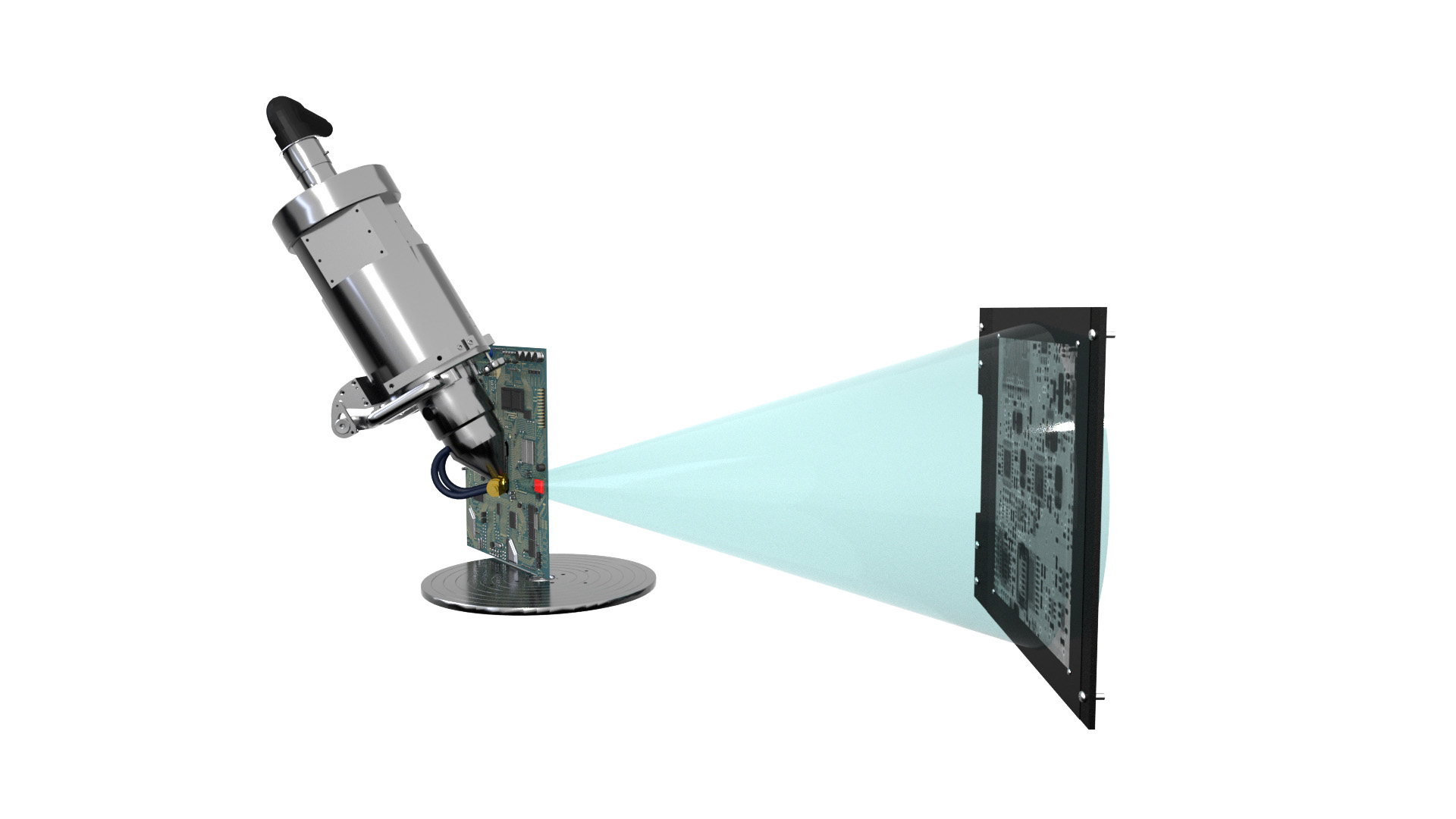

Owned by the Caulfield Industrial Group, E-Tronics operates throughout Europe as resellers of leading-edge, globally sourced production equipment and consumables, including the range of X-ray CT systems manufactured by the Industrial Metrology Business Unit of Nikon Corporation (https://industry.nikon.com).

The Gyor centre has two Nikon systems, an XT V 160 that is particularly well suited to production quality control of electronic components such as PCBs, BGAs and chips, and an XT H 225 system, which is ideal for high-resolution inspection and failure analysis of components ranging from tiny plastic connectors to large aluminium castings. In addition to selling these and other Nikon systems rated up to 450kV to local customers, Mr Kallai and his team provide subcontract inspection services. Demand has skyrocketed in recent years, so it now accounts for more than 25% of the entire business with more requests coming in all the time, particularly since the pandemic.

Mr Kallai said, “At E-Tronics we work with R&D, manufacturing engineers and purchasing teams from an early stage to ensure we provide optimal solutions to meet customers’ specific technical requirements. When we started the operation in Hungary in 2000, we were almost exclusively serving manufacturers of printed circuit boards and this is still two-thirds of our business. However, the automotive industry in this country is huge, employing around 180,000 people, and it has grown to account for most of the remainder of our turnover, with white goods, sensors and medical also contributing.”

Due to its sheer size, it is automotive production that offers the most exciting opportunities for E-Tronics in Hungary, but there are challenges, not least extended lead-times, price increases and an inexorable move from internal combustion engine vehicles to e-mobility. Many of the difficulties that manufacturers in the sector are experiencing can be mitigated by the use of non-destructive inspection of components, internally as well as externally, using the advanced range of microfocus X-ray CT systems offered by Nikon, which E-Tronics has represented since 2017.

Mr Kallai continued, “There is strong interest in AXI (automated X-ray inspection) among Hungarian automotive OEMs. Customers are enquiring about Quality 4.0 systems with autonomous operation built in, including parts handling and a conveyor. They want to detect anomalies that are normally hidden from view and use the data to optimise their production processes and eliminate scrap.

“Nikon’s new VOXLS X-ray CT solutions are perfect for automation, in-line or at-line, as they have fast-opening radiation doors and robotic handling options to achieve short inspection cycle times. They have metrology-grade, highly repeatable manipulation of the scan object. At E-Tronics, we are huge fans of this new equipment programme.”

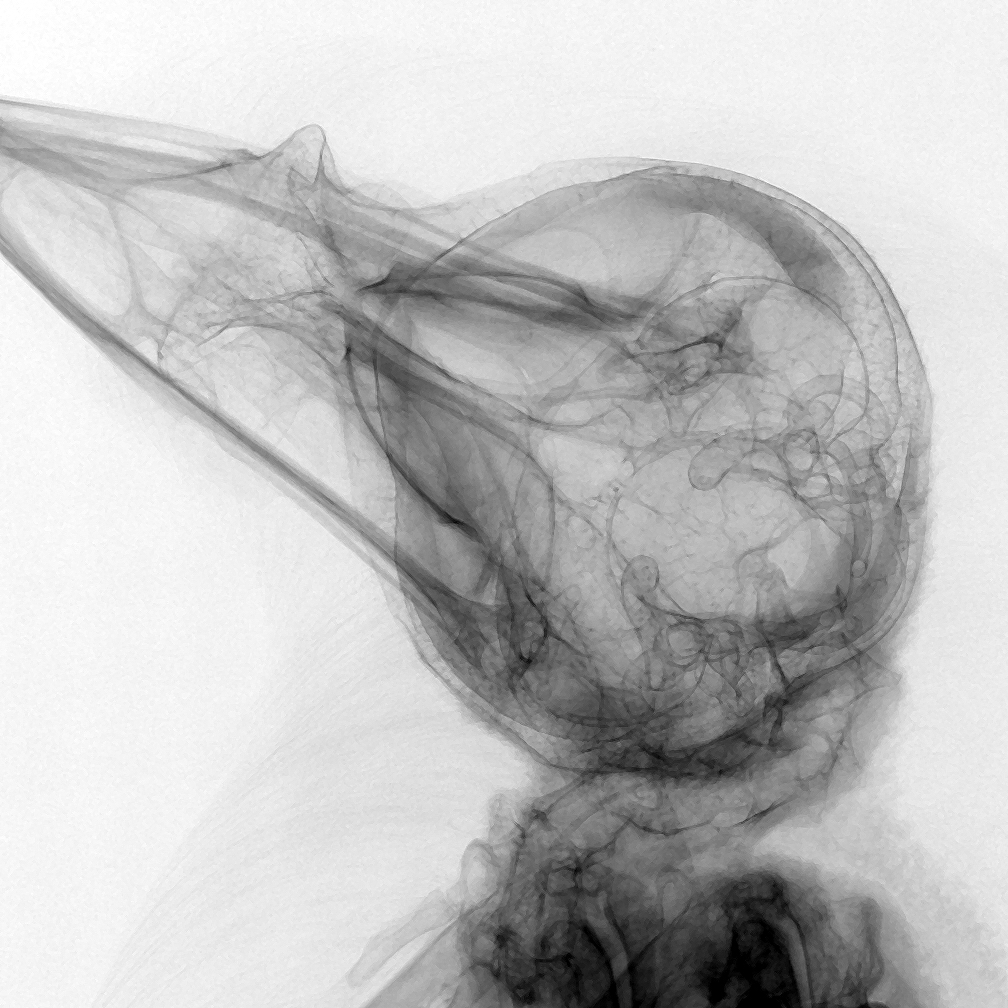

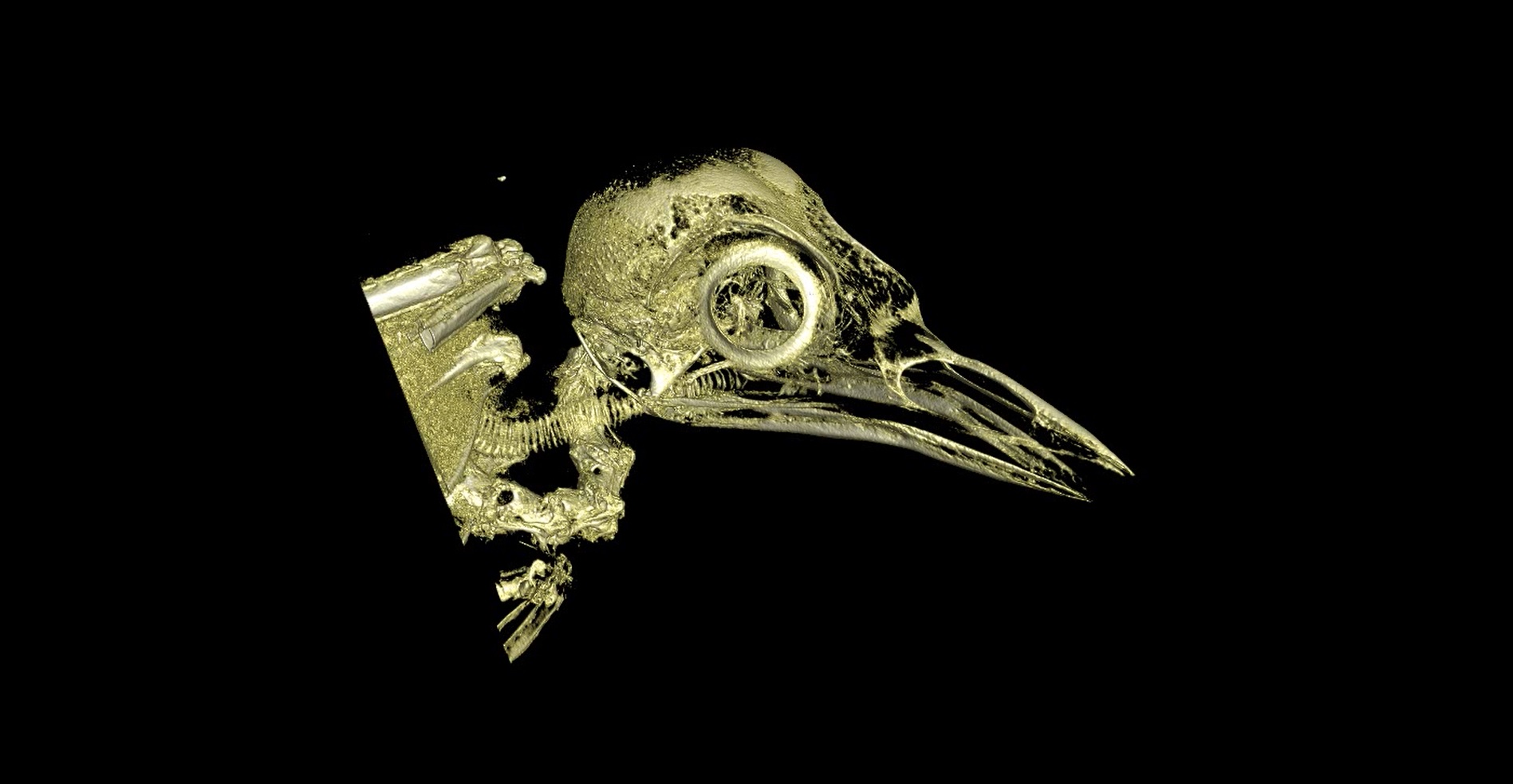

Various bizarre items have been scanned in the Nikon X-ray cabinets in Gyor. In one instance, a bird flew into a window and unfortunately broke its neck. Being interested in how the XT V 160 performs with low-density samples, the X-ray team decided to scan the area around the bird’s head.

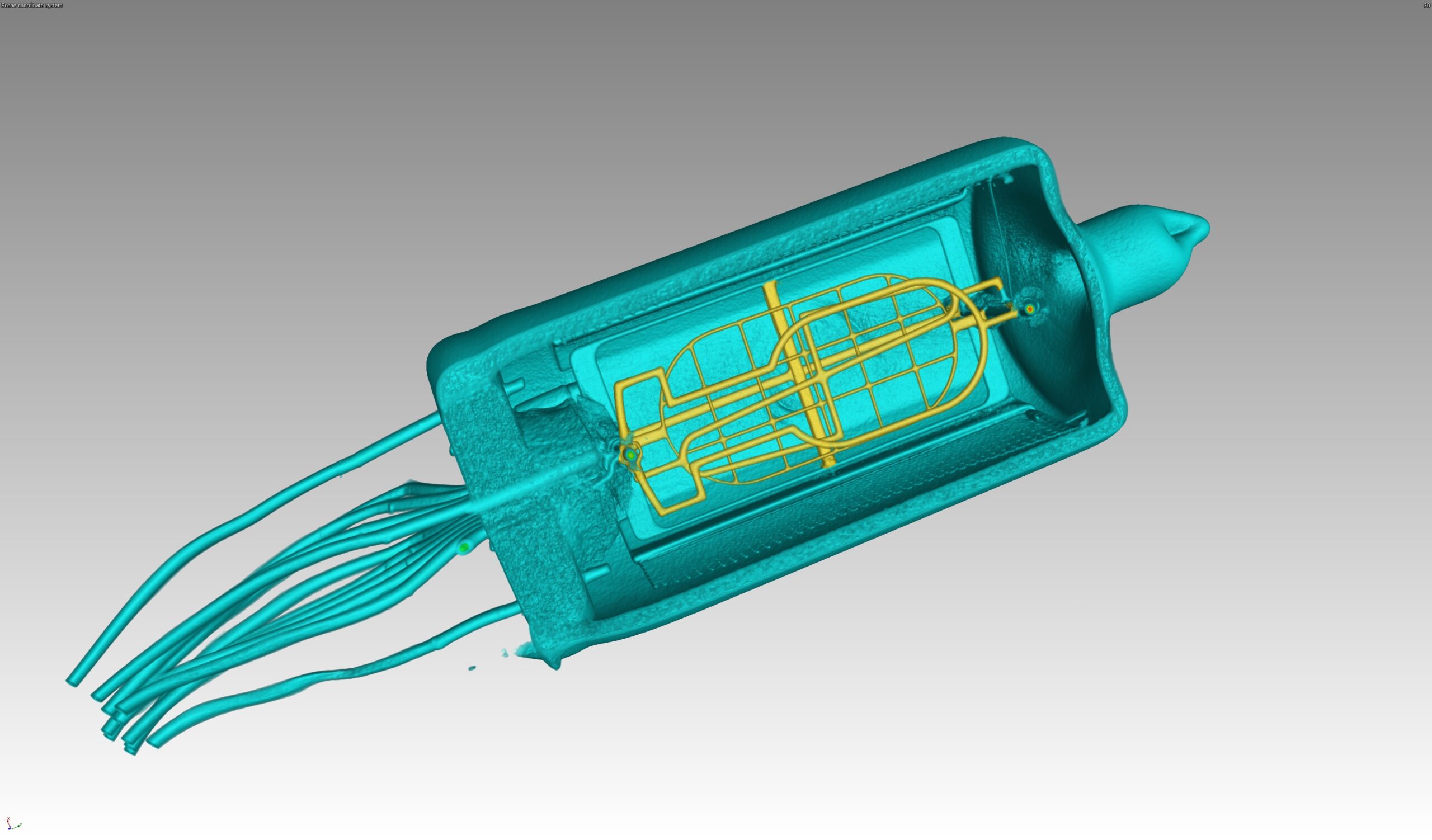

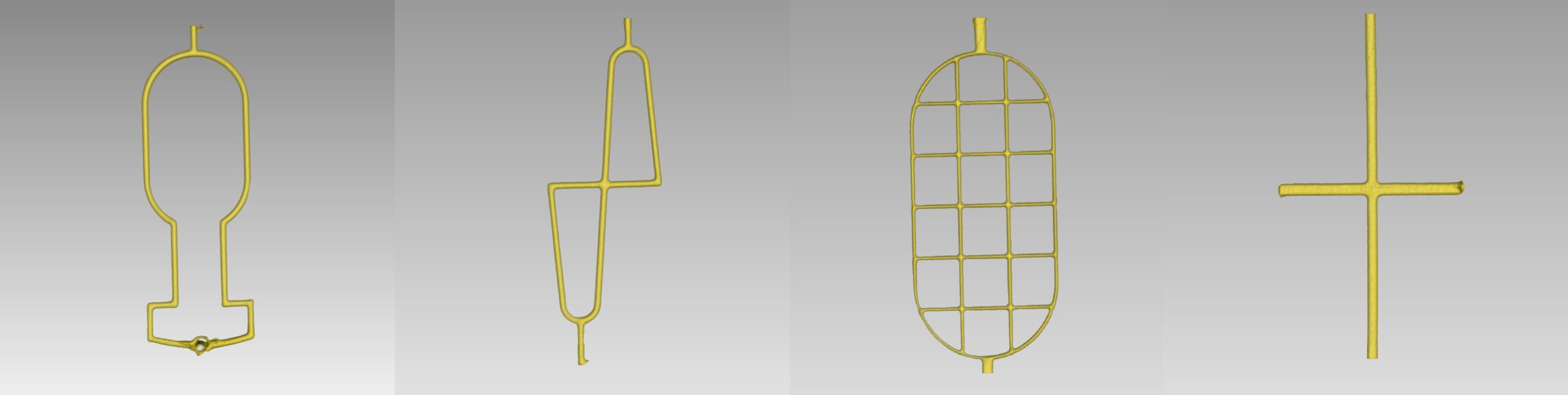

The same X-ray equipment was used to examine the interior of a Nixie tube, an electronic device that displays numerals or other information using glow discharge. The purpose of the demonstration was to determine whether the XT V 160, which is normally used for scanning flat objects, was able to deal with items that are non-planar.

Using Nikon’s X.Tract algorithm, which provides high-quality 3D inspection results from complex, multilayer electronics without using CT, virtual microsections were created revealing defects that could otherwise have been obscured. During this test, it was established that sharp images could be obtained all the way down the glass tube, with minimal occurrence of artefacts, by swivelling the detector through 60 degrees and tilting the sample slightly away from the vertical.

The XT H 225 was similarly put through its paces recently, scanning in one instance an automotive oil separator comprising a plastic valve with an accurately positioned O-ring. It was important to ascertain the precise positioning of the ring so that the customer could understand how its assembly operation was performing and whether it could be improved. X-ray CT proved perfect for the task.

A second experiment using the same X-ray system demonstrated an almost uncanny capability. Even children as young as three years old realise a chocolate Kinder egg contains a toy that needs to be put together, but it cannot be discovered without cracking the shell. The penetrating power of X-ray CT not only resolves the contents of the egg without destroying it, but subsequent use of software from Volume Graphics was able to identify each separate element and assemble them into a virtual toy.

Mr Kallai concluded: “For both the X-ray CT systems we sell and our subcontract inspection, Nikon’s powerful software is invaluable. One of the most amazing modules is High.Contrast Filter, which normalises and enhances contrast and sharpness across the whole of a 2D radiograph. It is especially useful for quality control of printed circuit board assemblies and other electronic circuitry such as ball grid arrays, as well as mouldings, castings and 3D-printed components.”

E-Tronics will take a stand at InnoElectro 2024, to be held in Budapest from 23rd to 25th April. Anyone interested in finding out more about the products and services the company provides, in particular those relating to 2D radiography and 3D CT, will receive a warm welcome on the stand.