Today we speak to Nathan Raymond, Field Service Engineer within the Microscopy Business Unit Europe, about his responsibilities and his expertise on the Wafer Loader NWL200.

- Could you please tell us your responsibilities within Nikon Metrology?

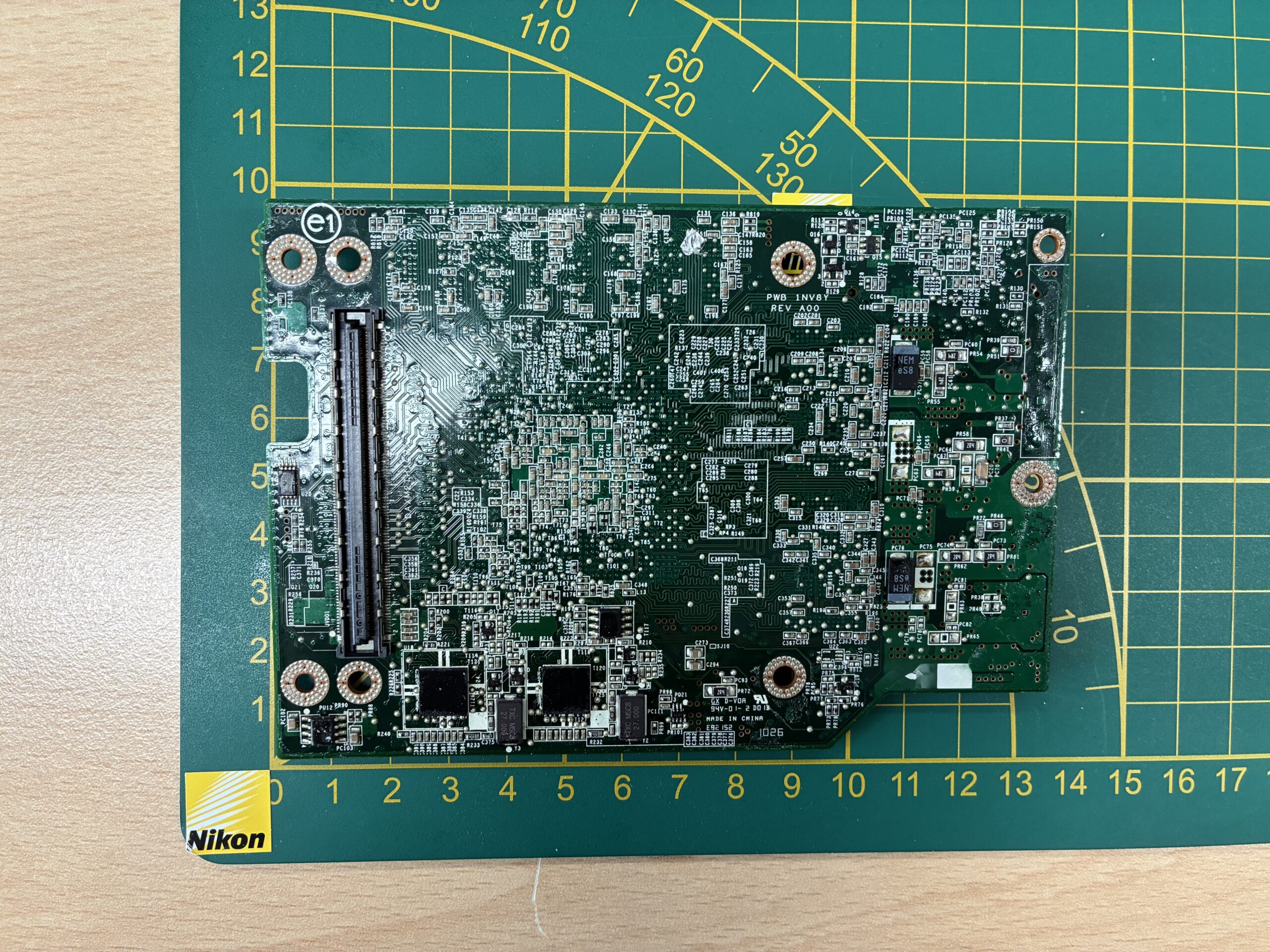

As a Field Service Engineer, I am in charge of the installation, calibration, maintenance, and technical support of our microscopy systems across France and Europe (sometimes North Africa). I work closely with both customers and internal teams to ensure the highest level of performance and reliability, especially on critical equipment such as the NWL200 wafer loader.

- What are the best parts of your job?

The diversity! No two days are alike. I enjoy the balance between technical challenges, autonomy on the field, and human interactions – both with customers and my colleagues. Travelling to various locations, solving problems, and making sure systems are fully operational is very rewarding.

- Any anecdote that you would like to share with our readers?

Most of the time, the NWL200 can be “repaired” remotely — sometimes even with a simple phone call. Just like this week: a client reached out in a panic because their machine wouldn’t initialize, which was going to slow down production significantly. Luckily, I knew the error code by heart, and I was fairly confident we could get the system running again without needing an on-site visit. Over a 20-minute call, I walked them through the steps to boost a voltage level and check the signal balance between two sensors — child’s play when you know what you’re doing! Sure enough, the machine was up and running by the end of the call. Later that day, I received a follow-up email with a big thank you from the client — moments like that are a reminder of how impactful good technical support can be.

- You travel to many customer sites for service, what are the main benefits customers experience from using the NWL200?

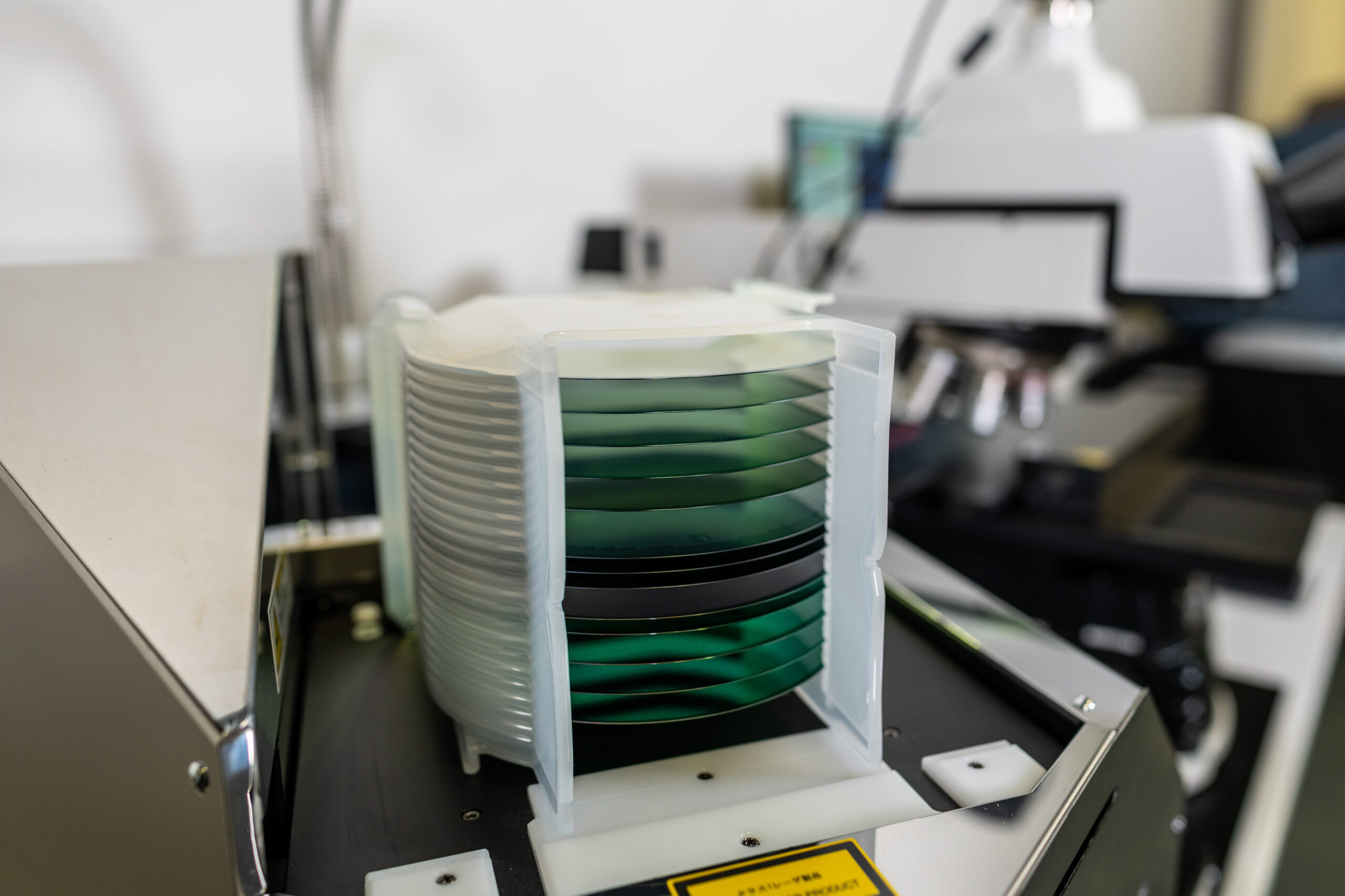

The NWL200 brings automation and stability to wafer handling. It reduces manual operations, which not only increases throughput but also protects fragile wafers from damage. Clients also appreciate its compatibility with various systems and the ease of integration in cleanroom environments.

- What sectors & industries can benefit from using it?

It’s widely used in the semiconductor and microelectronics industries, but also in R&D, materials science, and even medical device manufacturing—any field where precision wafer inspection is critical.

- As a Nikon Metrology Field Service Engineer, what is your favourite system feature of NWL200 & why?

Without hesitation: the robustness and consistency of the loading mechanism. Even in high-usage environments, the NWL200 maintains smooth, reliable performance. For a service engineer, that means fewer breakdowns, less downtime, and very happy customers.