Mark Eaton is a Sales Account Manager for the Laser Radar and Laser Scanning Business Unit. With his five years of experience with laser scanners at Nikon and his long time experience in quality engineering at a major automobile manufacturer, he is one of our experts working with handheld scanners. Today, we spoke to him about the Nikon ModelMaker H120 and the MCAx S arm and the benefits of their combination for customers.

Hi Mark, what is the ModelMaker H120 laser scanner?

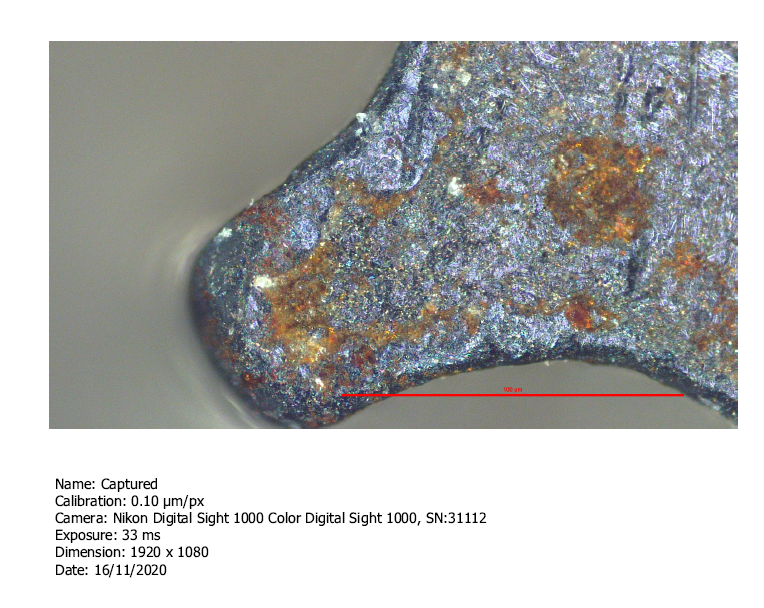

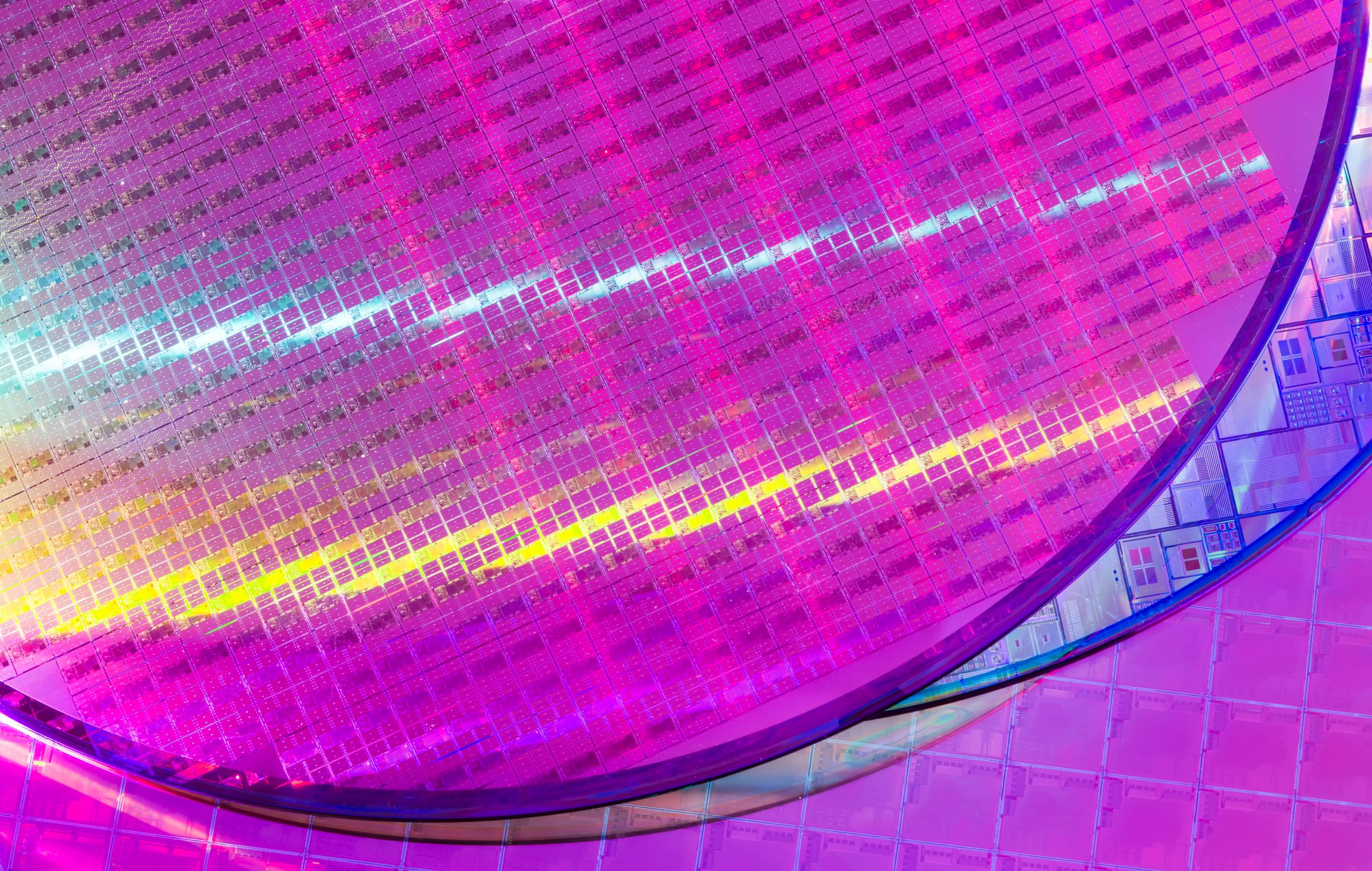

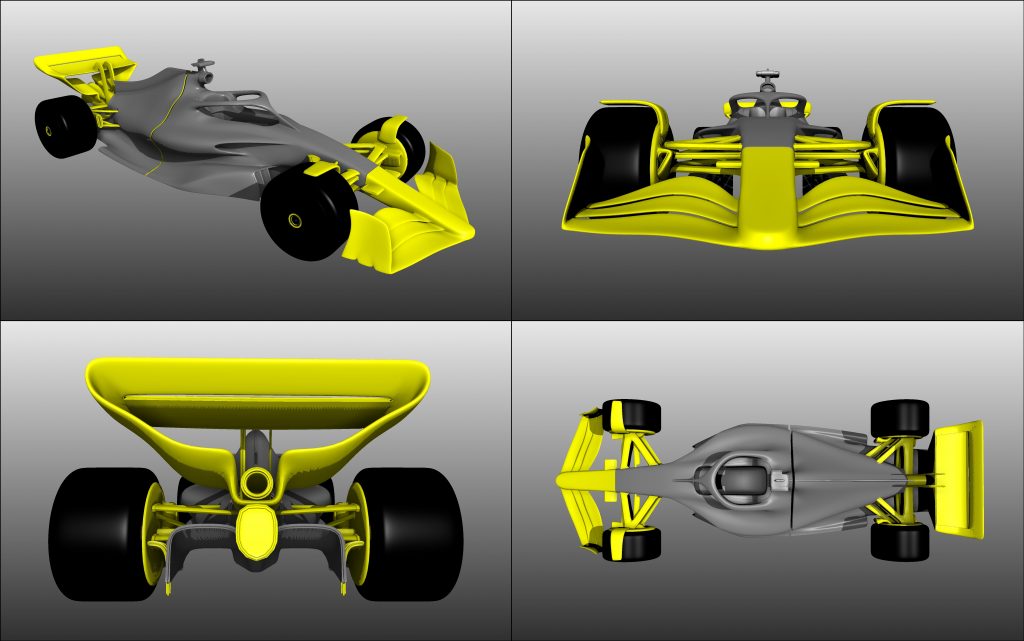

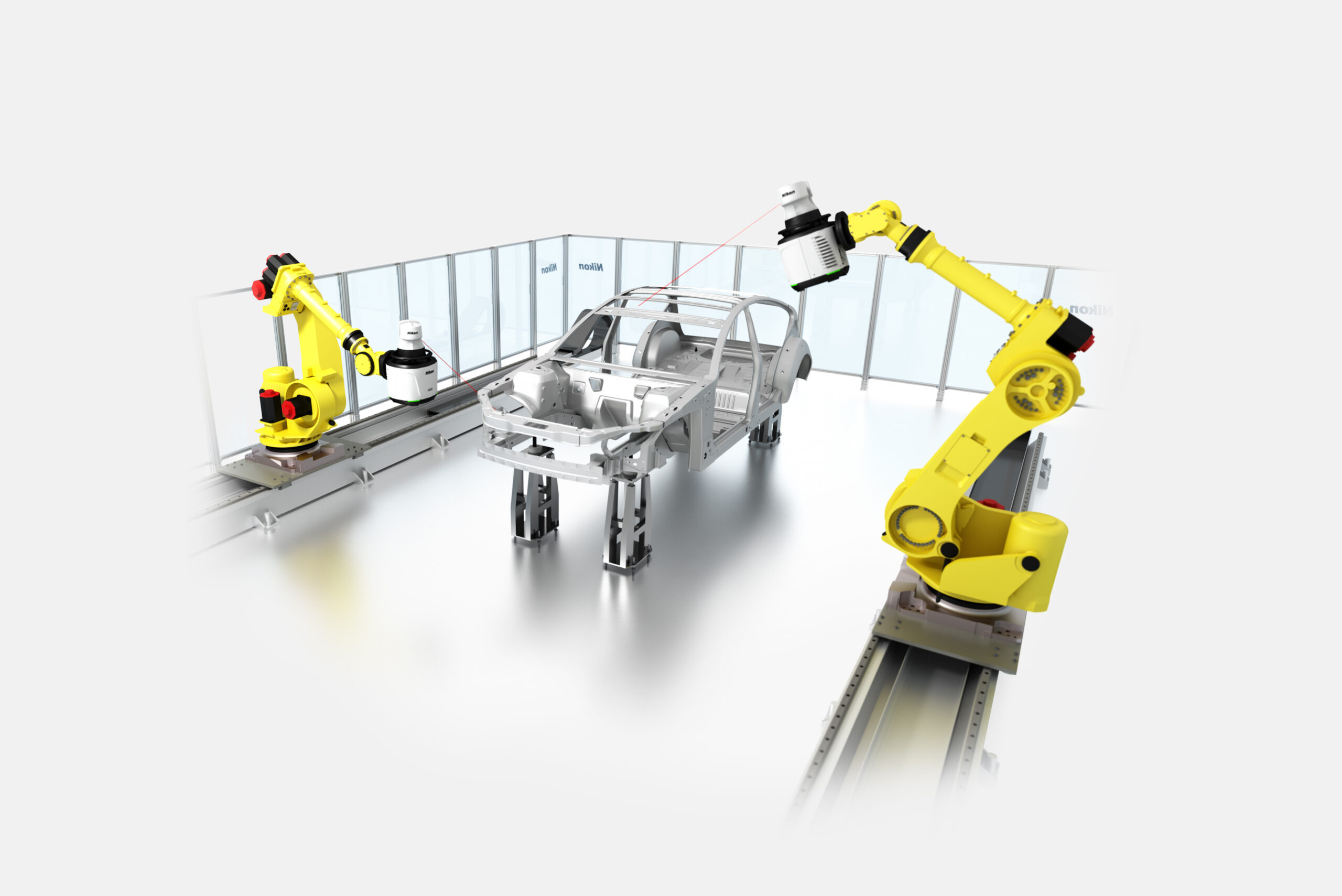

The ModelMaker H120 is our handheld scanner with blue laser technology and specially developed Nikon optics. It has an accuracy of just 7 microns which results in very low noise level. When it came out, it was the result of an evolutionary innovation within the product category of handheld scanners. Although the scanner and arm can be used in any industry and is able to provide direct insights and rapid feedback, our focus has been on automotive, aerospace and the general manufacturing industry. It is often used throughout the supply chain to larger OEMs, at Tier 1 and Tier 2 suppliers for precision engineering projects.

Why do we combine it with the MCAx S articulated arm?

Combining the H120 with the MCAx S arm gives the user unprecedented levels of detail and precision for a portable system that can be used across multiple locations from the lab to the shopfloor or at off-site locations. The scanner attached to the arm provides a good amount of flexibility, a high level of accuracy paired with an easy set-up. The repeatability of the scan results is great for a portable system. Additionally, the 7-axis articulated arm allows users to measure in and around parts without any hindrance.

What benefits can customers expect when using the Nikon ModelMaker H120 laser scanner and MCAx S arm combination?

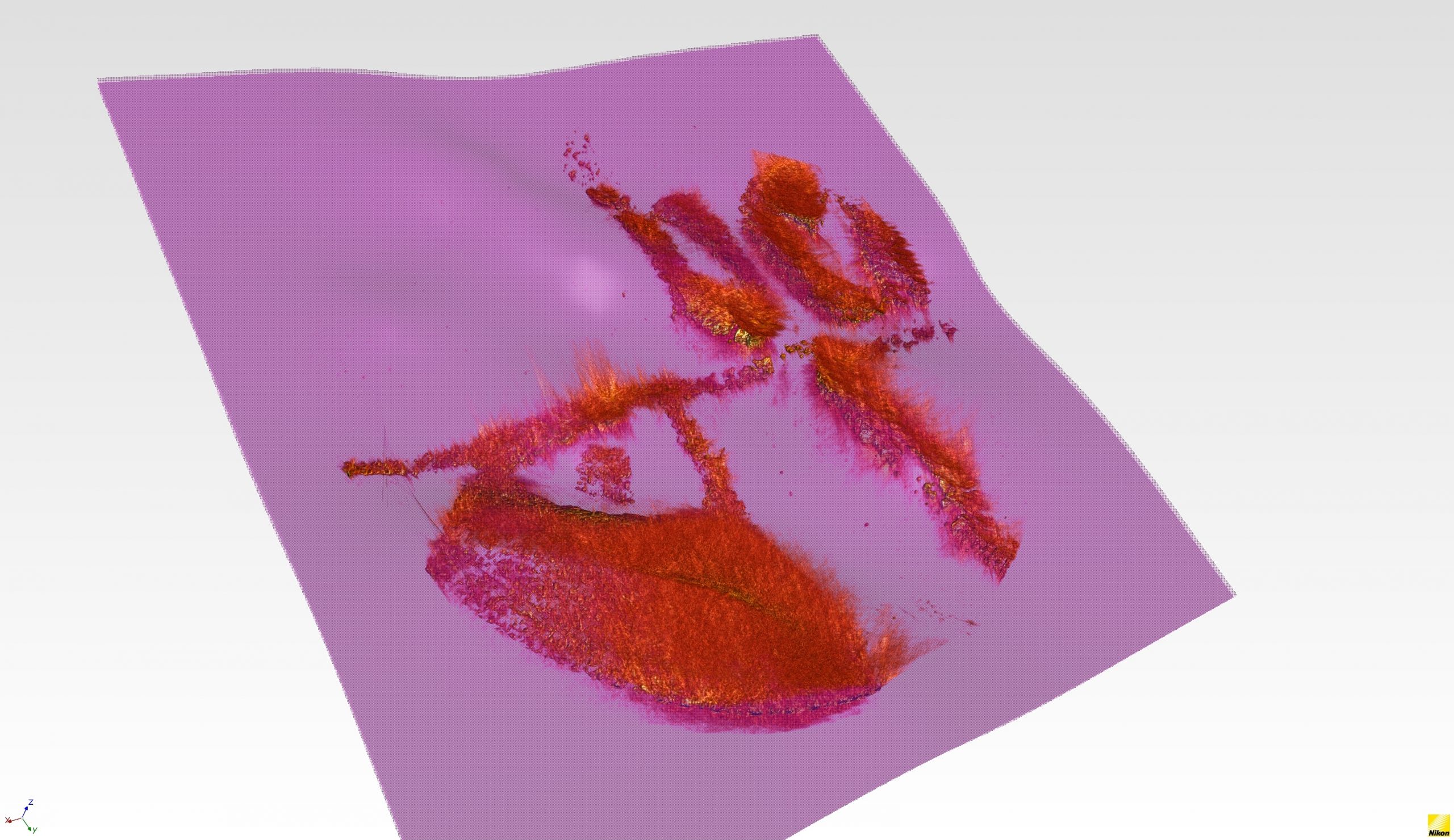

Customers will benefit from a class-leading handheld scanning system, capable, with the use of dynamic laser power control, of scanning almost any material. Now, with the cable free scanning, the system can be used in many different environments without having to compromise on performance or accuracy. A pain point many companies are facing is the lack of accurate and speedy feedback into the quality of components. With the ModelMaker H120 laser scanner and the MCAx S arm, Nikon provides a huge benefit: efficient and cost effective results. With these insights, it gives the customer a much greater opportunity to create a “right the first time” culture within their manufacturing processes and improved visualization of problems found.

What sectors & industries benefit from using it?

The great flexibility of the system allows it to be used across many different industries and applications. Core industry users include automotive OEMs and their supply chain, aerospace and precision engineering. Our high-quality data is also ideal for those looking for the perfect tool for reverse engineering projects – and here the ModelMaker H120 laser scanner and the MCAx S arm can scan any imaginable component. Just to give an idea about the wide range of possible applications: the solution is perfect for automotive parts on the shop floor as well as superman statues and fun Halloween masks if that is what a user wants to scan.

What is your favorite feature of the MCAx S arm & why?

There are so many great features in our system, it’s difficult to have just one favorite, I can narrow it down to two…..Firstly, the H120 “Field of view” indicator really gives the user fantastic real time visual feedback on what they are scanning as they move across the surface of the component, and secondly the truly wireless scanning function, with the addition of the optional wireless control pack gives the user four hours wireless scanning without any reduction in scanning speed or quality of data. The flexibility and productivity offered by the system is fantastic – a truly anywhere, anytime system – it measures almost anything to near CMM accuracy with minimal training. Just to add to that productivity: It is not just about the speed or scan results, is a combination of that and the minimal set up time, no need for special settings or multiple redundant scans.

We would also like to take this opportunity to introduce to you our partners in the United Kingdom: Laser Scanning UK Ltd. With over 30 years of engineering experience, Managing Director Johnathan Rigby and his colleagues make up the perfect team to offer UK sales and service centred around 3D laser scanning, inspection measurement, reverse engineering, rapid prototyping and augmented reality. We are proud to have such a hands-on and successful partnership in the UK, that masters product demonstrations and product services of our Nikon products in our name. If you are interested in a demo or more information, please visit their website.

Get in touch to discuss your requirements or to simply request a free virtual demonstration. We’d love to help you find the right solution.

[maxbutton id=”1″ url=”https://www.nikonmetrology.com/en-gb/3d-metrology/manual-3d-scanning-h120-mcax-s-system” text=”Visit Website” ] [maxbutton id=”1″ url=”https://www.nikonmetrology.com/images/brochures/mcaxs-modelmaker-h120-07-20-en.pdf” text=”Download Brochure” ]