Here at Nikon Metrology we offer a wide range of products to support your gear production

Perform gear analysis using Nikon’s range of Stereo and Metallurgical Microscopes, precisely measure gears time after time with Nikon’s NEXIV video measurement systems and even using the JEOL NeoScope JCM-7000 benchtop Scanning Electron Microscope for both chemical composition, defect inspection or failure studies.

VIDEO MEASUREMENT

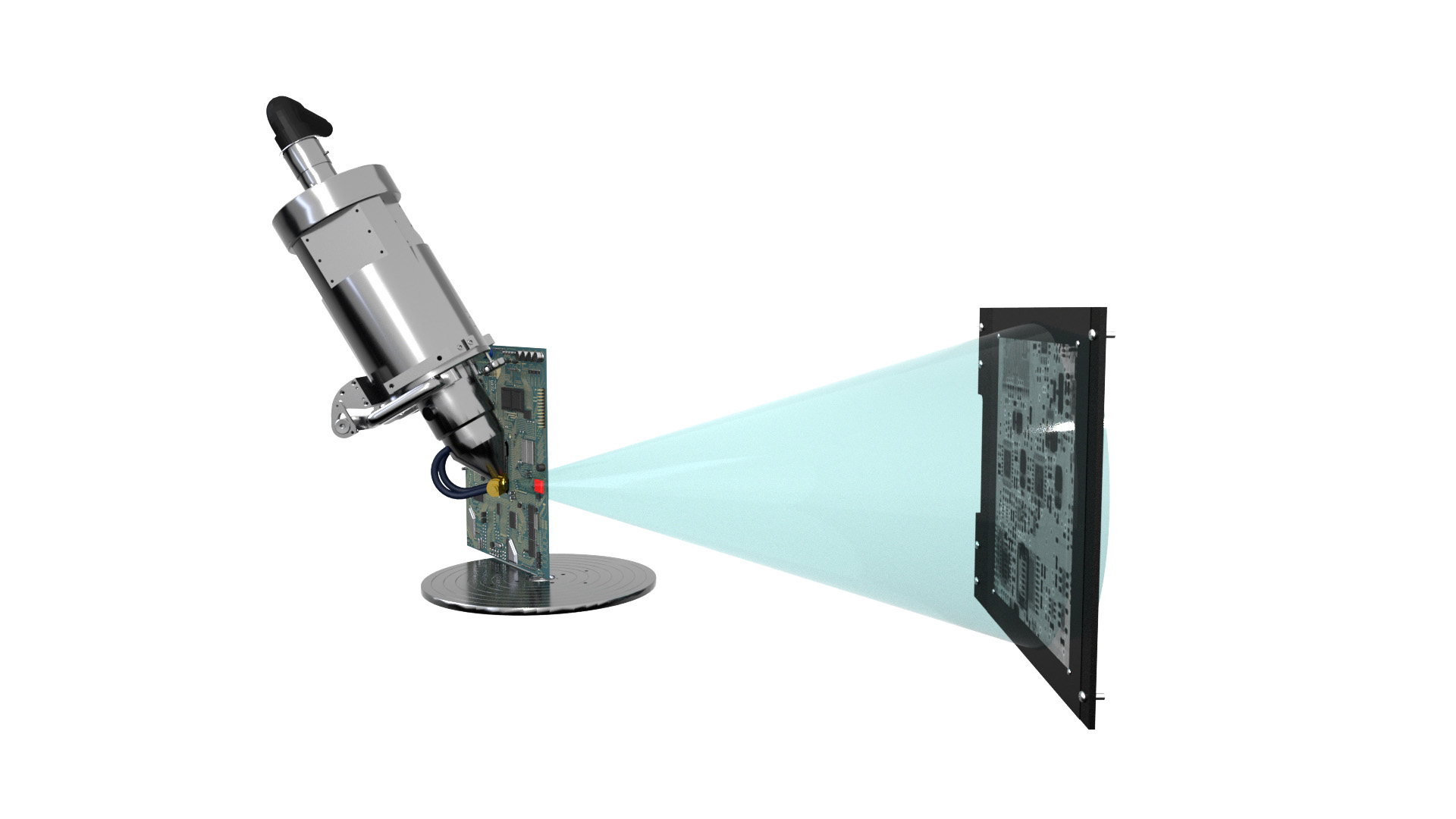

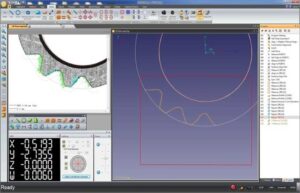

NEXIV – Nikon’s non-contact video measuring system, which is changing the way we measure.

The Nikon NEXIV product range offers a fully automated quick, accurate and repeatable measurement solution, in an extremely strong machine. Primarily the NEXIV works as a non-contact system using Nikon’s excellent zoom optics together with a camera and automated edge detection software algorithms.

The NEXIV system offers an excellent solution for small or plastic spur gear evaluation.

Key benefits include:

- Quick throughput of measurement

- Excellent accuracy and repeatability

- Ease of use

- Non-contact measurement

- CAD Comparison

A simple and quick process, the profile is automatically scanned using non-contact video edge detection. It is then evaluated against the gear data or alternatively as a profile for comparison against the nominal CAD data.

To take your first step in your NEXIV journey and take precision seriously – click here.

MICROSCOPES

Metallurgical Microscopes

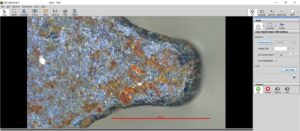

The Nikon Eclipse LV Microscope can be used for optical inspection and cross section of gears. The magnification achievable is between 25x right up to 1500x and even resolves defects under 1 micron in size. Making this microscope ideal for inspecting your gears with great confidence.

When combined with a Nikon Digital Camera and the NIS Elements software package, this further expands your ability to analyse metallic grain size, material porosity, dimensions of cracks, defects and wear.

Key benefits include:

- Modular system with component concept

- Wide choice of observation methods and contrast techniques

- Exceptionally robust and sturdy design

- Operator friendly

- Ergonomic

To learn more about Metallurgical Microscopes – click here to visit our website.

The images show a simple report obtained with a 50x magnification objective using a Nikon LV Microscope with Nikon’s Digital Sight 1000 Camera and NIS Elements F software.

By using Nikon Metrology’s Digital Sight camera range – you can utilise accessory modules inside the NIS elements software suite to automatically provide super-fast results from samples of cast iron, to multi-layer thickness measurements present in plated materials.

To learn more about the benefits of Nikon’s Digital Microscope Cameras – click here

Stereo Microscopes

The Nikon SMZ 1270i offers a zoom ratio of 12.7:1 allowing for fast inspection of gears for defects in quality control. The incredible image sharpness is present throughout the wide field of view even at low magnification, giving pin sharp resolution to the eye pieces. This output can also be available using a Nikon digital camera for operator ease of use and report generation.

Key benefits include:

• 12.7:1 zoom ratio

• Wide-field plan apochromat and plan achromatic

• Intelligent zoom integration with NIS Elements software suite

• On axis observation option

• Ergonomic trinocular head design

To learn more about Stereo Microscopes and how they could benefit your processes – click here.

SCANNING ELECTRON MICROSCOPE

The JCM-7000 NeoScope is the net generation of Scanning Electron Microscope (SEM) developed by JEOL with Nikon Metrology. By utilising backscatter (shadow, topography and composite) detector imaging with secondary electron detection imaging – the JCM-7000 can be an essential tool integrated into production and research activities over a wide variety of applications.

Key benefits include;

- Larger sample chamber for faster evacuation

- Zeromag software:- easy transition from optical to SEM image

- Simple report creation and data management

- Live Element Detection overlaid onto the live image

- Auto re-construction of image in 3D during observation

Get in touch to discuss your requirements or to simply request a free virtual demonstration. We’d love to help you find the right solution. Contact Us