With medical devices, failure is not an option. From the simple to the most complex applications, the reproducible examination and inspection of key components is vital. With the high image resolution and ultra-fast CT reconstruction, the sharp images provide a fundamental insight to ensure reliable and repeatable performances. X-ray CT is particularly suited to verify the dimensions of drug delivery systems’ inhaler chamber or dispenser mechanisms, syringes, stents, pacemakers and many more.

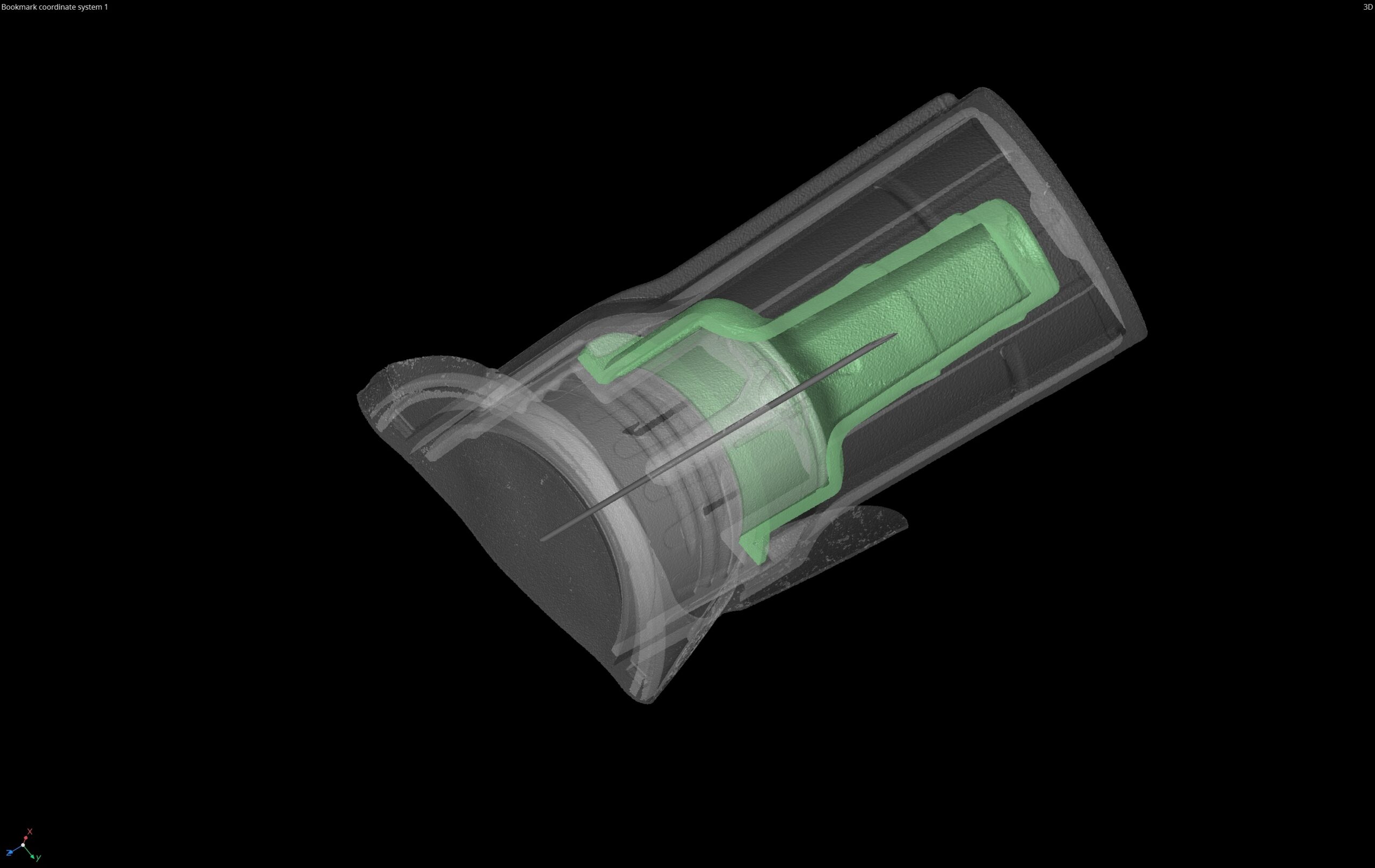

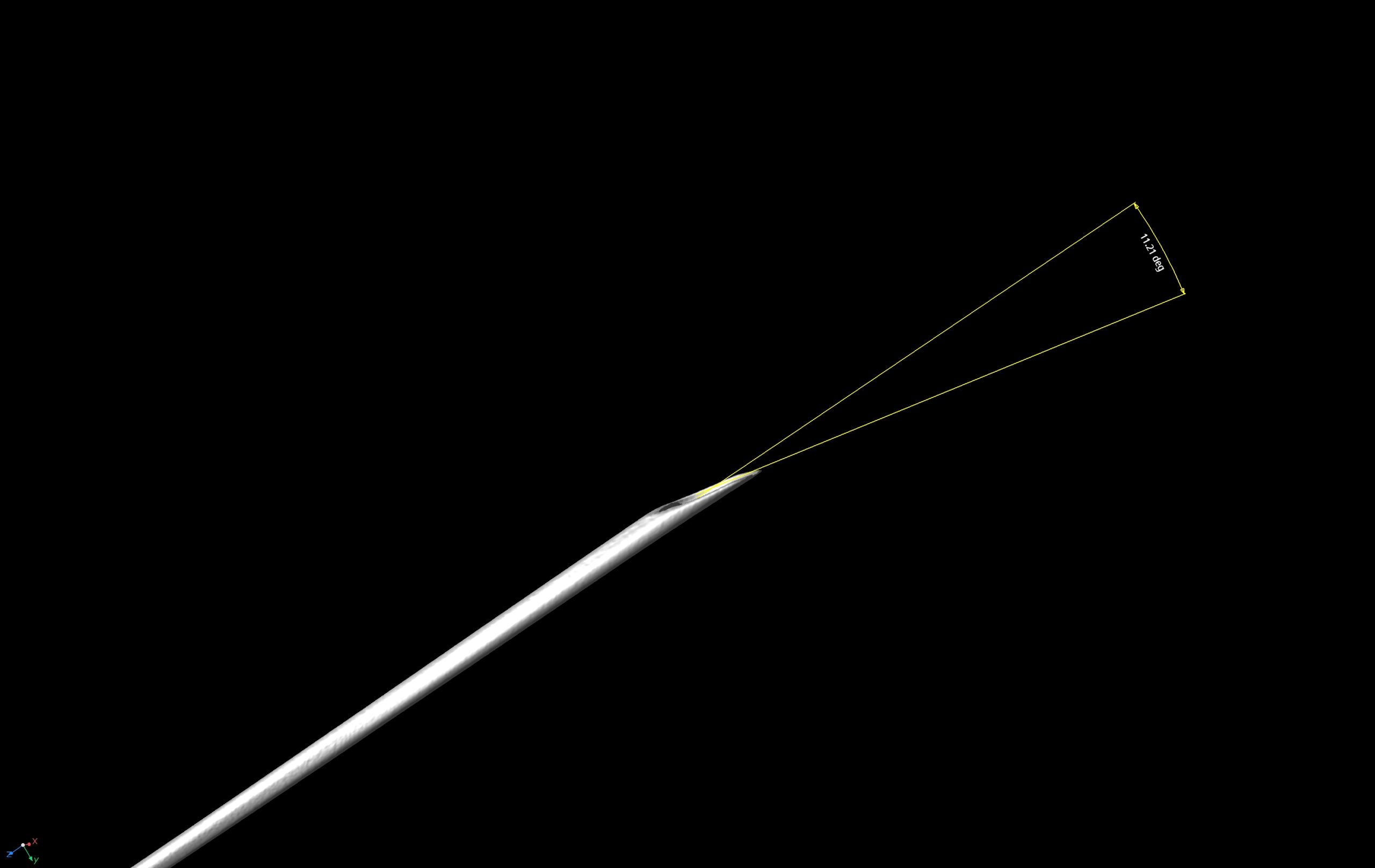

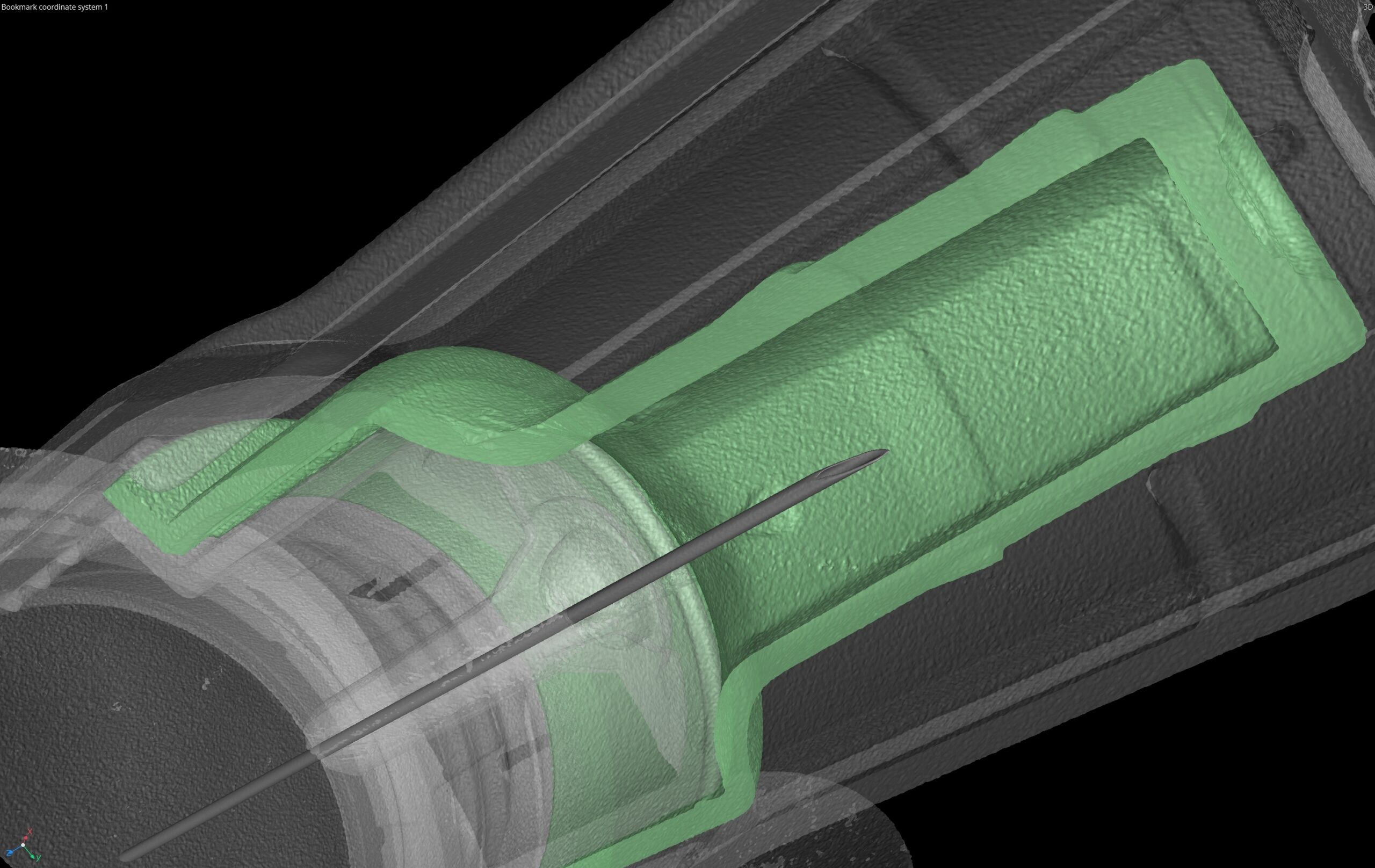

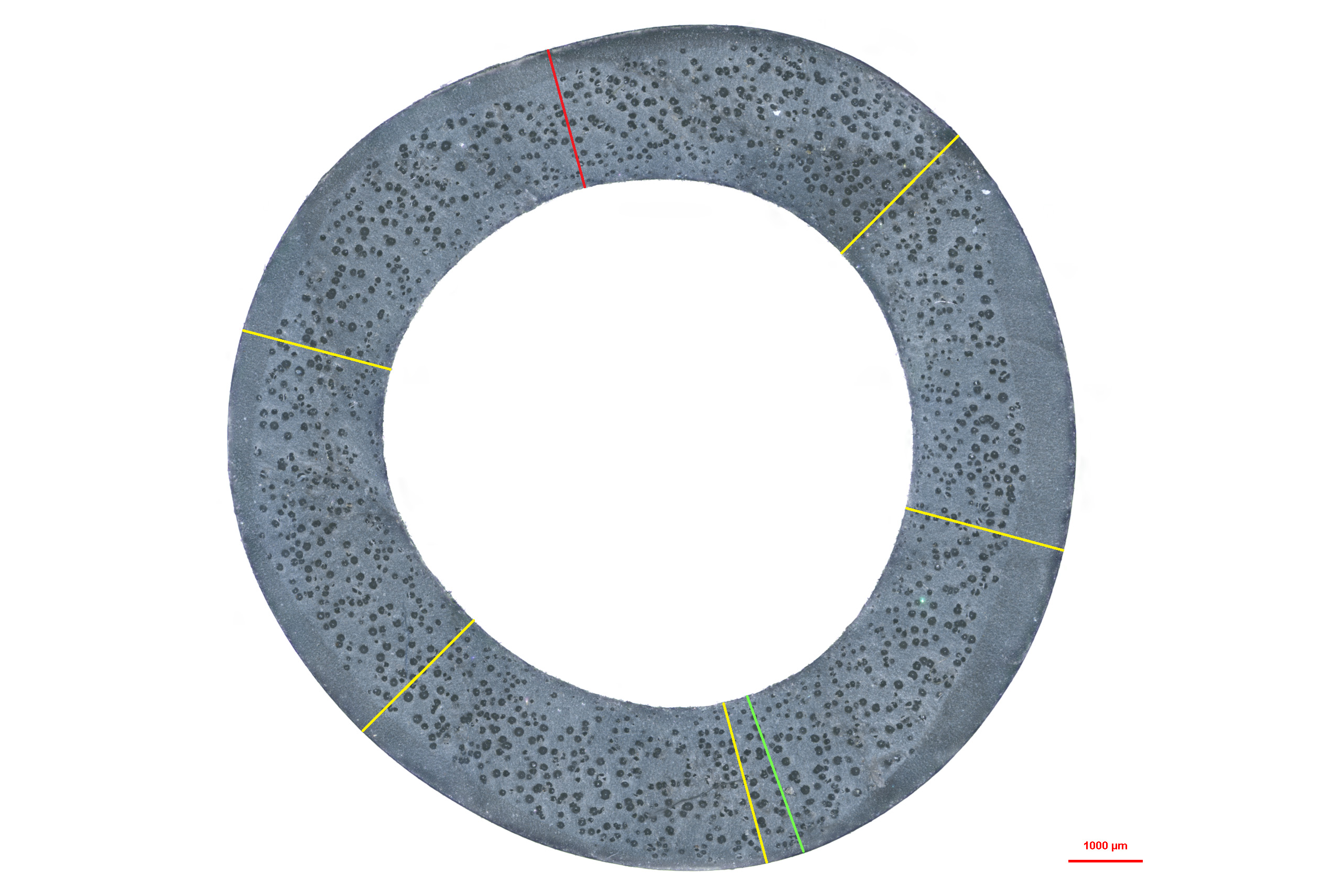

This month, Thomas Dreisbusch (X-ray Application Engineer), scanned an insulin syringe. X-ray CT enables us to non-destructively inspect the metal as well as the plastic of the needle. The resolution of the needle should be high enough to display it even though the needle was scanned with packaging.

The X-ray CT scan was acquired at a voxel resolution of 7,4µm while using 150kV potential and 7,5W X-ray power. The scan was acquired using a Nikon XT H 225 ST, which houses a Nikon 225kV microfocus X-ray source, coupled with a Varex 4343-CT flat panel detector. For this scan, the detector acquired 5800 projections at an exposure of 2000ms using Nikon’s helical acquisition and reconstruction algorithms to construct the 3D model.

If you want to learn more, do not hesitate to register to our next webinar which will give you a good overview of the possibilities of X-ray CT for the Inspection of Medical Devices and how it may benefit your applications.