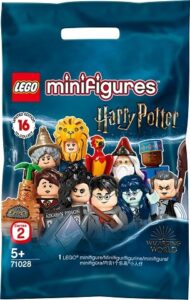

This (magical) scan of the month features a LEGO® Minifigures polybag, performed by applications engineering manager for X-ray & CT Lauren Enghien. X-ray CT enables the non-destructive visualisation of the inner structures and defects of assemblies and individual parts – such as metal additively manufactured parts – and simulates their behaviour before being installed.

The scanned object contains a LEGO® Minifigure that cannot be identified from the outside. The figure contents are unknown, with such items always a surprise for collectors. By using CT, we were able to find out which LEGO® Minifigure was inside the bag without having to open it. We made it possible to predict the mystery figure inside!

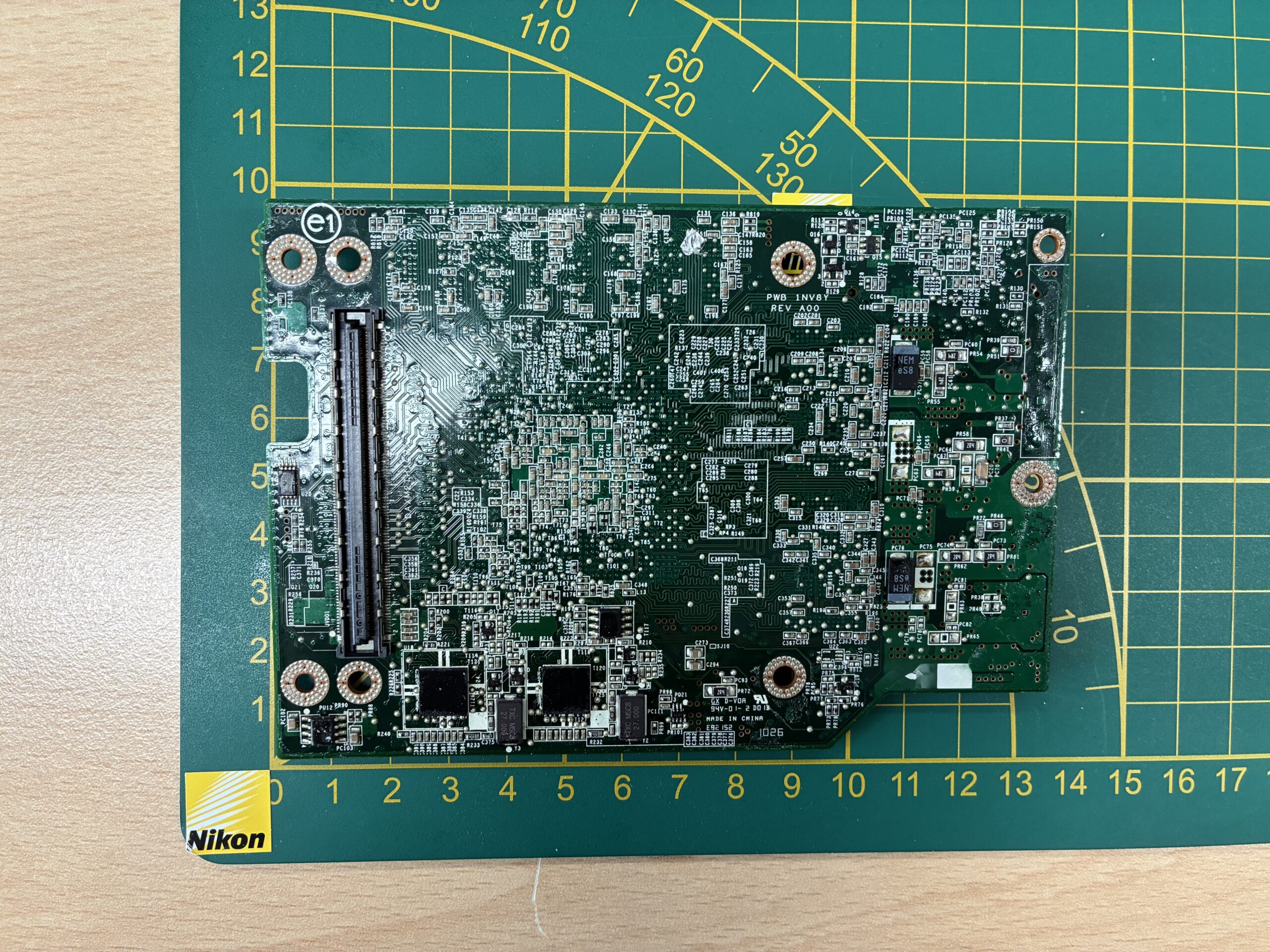

This X-ray CT scan was acquired using Nikon’s helical acquisition algorithm (X.tend) at a combined X-ray power of 40 W and a voxel resolution of 45 µm, using a Nikon XT H 225. This system comes equipped with up to two different Nikon microfocus X-ray sources: a 180 kV, 20 W transmission target and a 225 kV, 225 W reflection target. This scan was performed using the 225 kV reflection target option, coupled with a Varex XRD 4343CT flat panel detector.

For this scan, the detector acquired 5812 projections (individual radiographs) at an exposure time of 177 ms, resulting in a total scan time of 34 minutes; a longer scan compared to the speed of our X-ray CT scans that can be as low as 1 minute with a configurable number of projections.