Ben Morgan, Product Manager for the X-ray Business Unit, has been working within Nikon Metrology since 13 years. Today we spoke to him about his responsibilities, his expertise and about the new XT H 225 ST 2x launched few weeks ago.

Hi Ben, could you please tell us what are your individual responsibilities within Nikon Metrology?

I am a product manager for the X-ray Business Unit and it is quite a varied role at Nikon Metrology, addressing Product Manager, Product Marketing Manager and Global Application Engineer responsibilities. This results in a broad set of responsibilities throughout the product lifecycle, including representing the voice of the customer within the company to gather and prioritise requirements of our products to define the product vision and working closely with engineering to write detailed product specifications and deliver innovative products. It also includes developing effective marketing strategies and creating marketing communications content to communicate the features and benefits of our products both internally to our sales and marketing teams, and externally to our customers.

What are the best parts of your job?

I think the best part of the product manager role is the opportunity to utilise creativity and play a key role in defining the products that deliver positive change to the company, our customers and contribute to being a world-leader in our industry field. There is a great deal of satisfaction in seeing first hand how your solution is helping to solve a customer’s problem.

Travelling is also a great part of my job, I’ve visited too many places to remember, being with Nikon has taken me to China, Japan, Taiwan, Singapore and all over the USA. Many of these I probably wouldn’t have managed to visit without the job role and often it is to places that are not your big city tourist destinations; which gives a different perspective of the areas because you’re also working alongside the local representatives.

Having worldwide colleagues is also another nice aspect of my job. Travelling to their offices, their customers, socialising with them and working closely together gives you a great insight into the different cultures of the world we live in.

Any anecdote that you would like to share with our readers?

The world of X-ray CT is incredibly diverse, it is one of the most stimulating aspects of working in X-ray CT in my opinion. One day you can be sat around a table of expert motorsport engineers at the forefront of technology in F1 and the next a table of experts on the history of life from the world’s leading museums and research institutes!

One of the most memorable projects over the years, was when I met Stan or at least part of him. At the time, Stan was the second most complete T. rex fossil discovered, and the reason that I got to handle this piece of history was that Stan has the most complete and perfectly preserved skull found to date. It is widely regarded as the best T. rex skull ever discovered. This allowed researchers to study the brain like they never had before, which if you’re interested, is larger than the human brain and more of a cylindrical shape. It was an exciting but also a very nerve-wracking project; it’s not often we handle samples that are described as priceless. In 2020 Stan sold for $31.8 million, so maybe not priceless after all.

You recently launched a new X-ray CT system, what benefits can customers expect when using it?

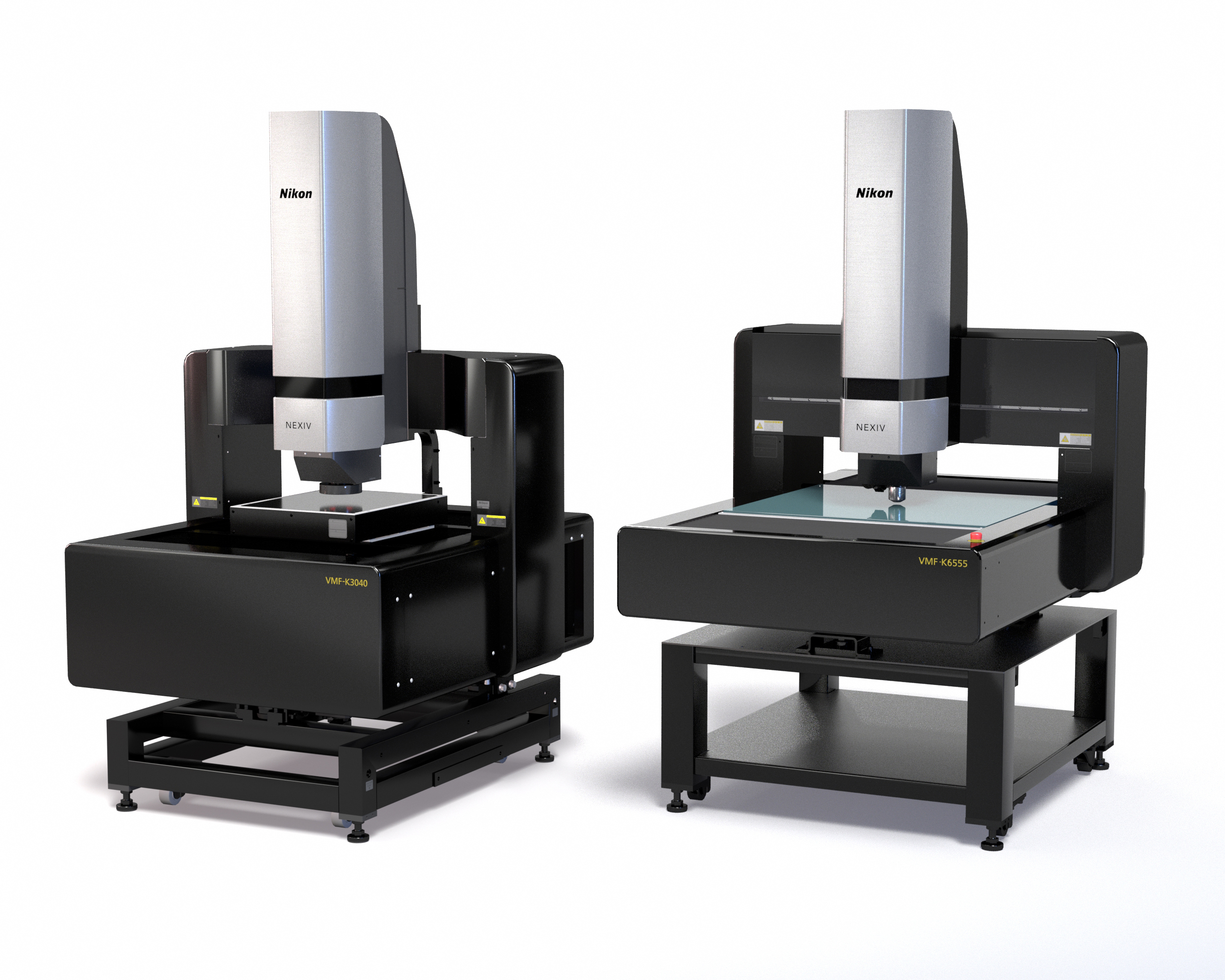

The XT H 225 ST 2x system offers a unique combination of five innovative features, which customers can expect to bring them improved productivity, data quality and accuracy.

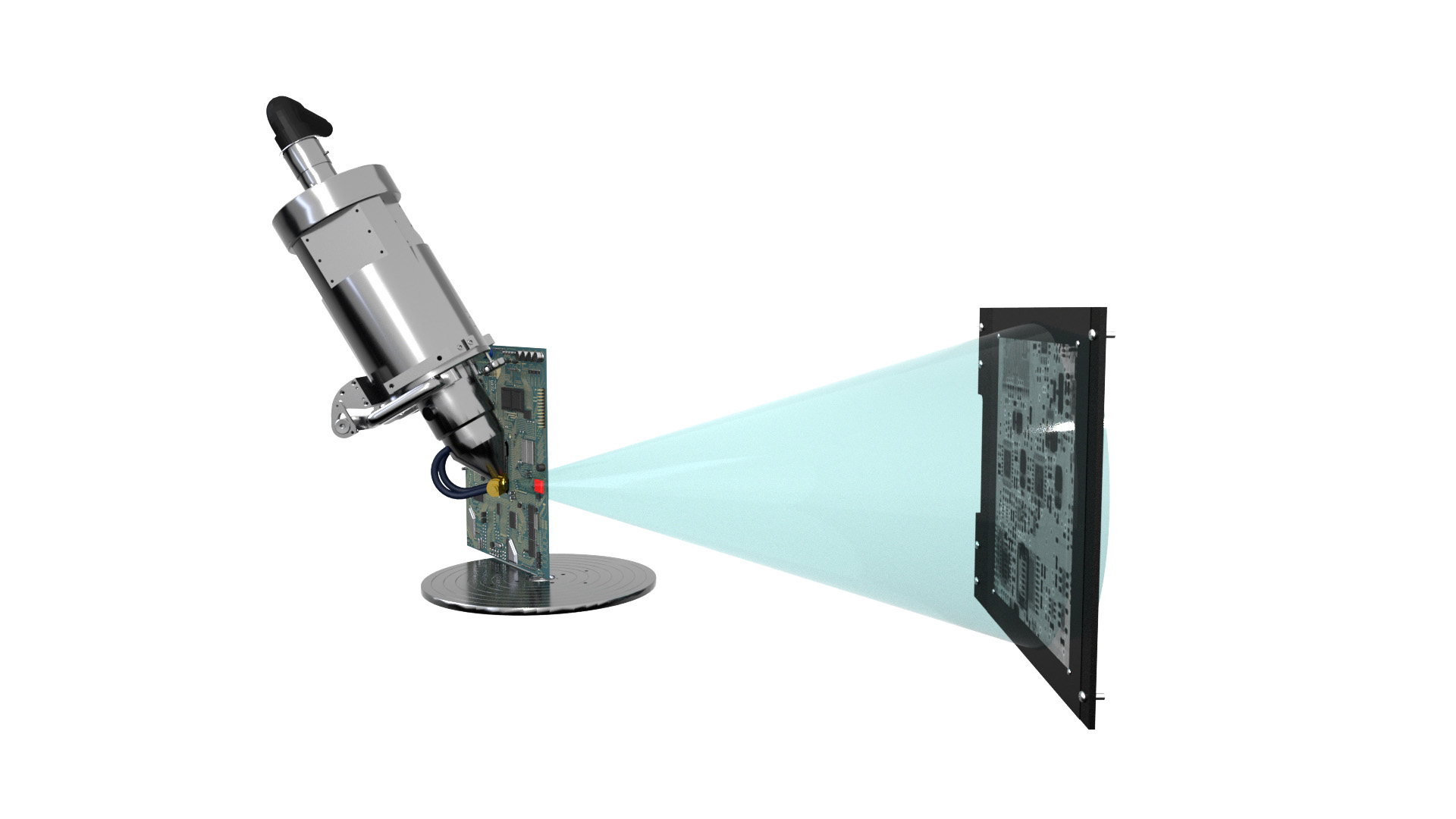

With the Rotating.Target 2.0 the second generation of 225kV rotating targets is born, a unique capability to Nikon which offers incredible resolution at high powers.

Auto.Filament Control intelligently controls the X-ray source to double the lifetime of the filament, meaning that the system is available more of the time.

Half.Turn CT allows faster CT scans by only rotating the sample just over 180 degrees, Local.Calibration makes automated calibration of any CT scan position possible leading to improved measurement accuracy for metrology applications and Quick.Change reduces downtime and delivers optimal performance from filament changes.

If you want to know more, get in touch to discuss your requirements or to simply request a free virtual demonstration. We’d love to help you!

What sectors & industries benefit from using the Nikon XT H range?

All of them, I know it sounds like a lazy answer but the applications of our X-ray CT systems is huge. Since I’ve been at the company I have been involved with companies from the more conventional industries of automotive and aerospace to food & drink and agricultural; which most people might associate less with NDT and measurement. The ability to see inside without destroying the sample knows no bounds of the industry! On a more serious note, I’ve certainly experienced a more mainstream adoption of X-ray CT during my career so far, and arguably the sector benefitting most from recent advances in technology is manufacturing, where our innovations in automation and speed are enabling the use of X-ray CT in production.

As a Nikon Metrology expert for the XT H 225 ST 2x, what is its favourite feature & why?

Good question; this is like asking someone which of their children is their favourite! I think I would have to go for the Rotating.Target 2.0, the uniqueness is a great headline but the unrivalled capability of the target truly sets it apart from anything on the market. I always remember the first impression the target left me with, I couldn’t believe the speed I was able to scan with and the resolution quality I was still achieving.