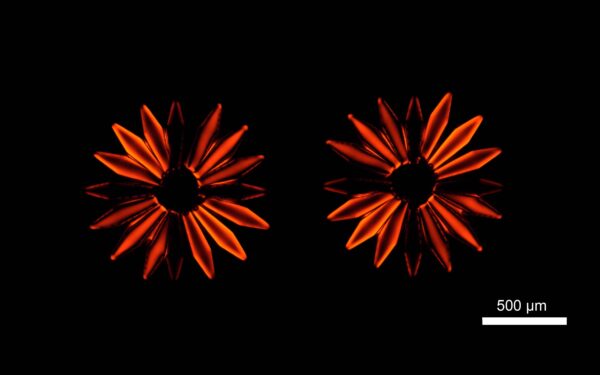

Researchers at the University of Texas at Austin are pushing the boundaries of liquid crystal polymer analysis using Nikon’s Eclipse LV100ND microscope. This industry-leading technology enables real-time visualization of molecular alignment, paving the way for next-generation industrial applications.

Today’s leading research institutions in chemistry and materials science have specific and demanding inspection requirements that help push the boundaries of industrial microscopy. Much of this research has a direct applicability for industry, not only in showing what microscopes can do but also in creating next-generation consumer products.

Joy Zhou, a student and researcher within the Department of Chemistry at The University of Texas at Austin, working with her advisor, Dr. Zachariah A. Page, conducted a series of experiments to characterize the nature of liquid crystal polymers under particular conditions. Their tool of choice to analyze these polymers is Nikon’s Eclipse LV100ND upright microscope with episcopic (reflected) and diascopic (transmitted) illumination.

Analyzing the unique qualities of liquid crystals

Discovered in the late 19th century, liquid crystals are a type of matter with unique properties, in that they can flow like a fluid and maintain a common direction as solids do on a molecular level. These properties make liquid crystals useful in fields including electronics, semiconductors, optics, and medical devices.

Inducing molecular alignment in liquid crystals is necessary to research new applications for these materials. This can be accomplished through

contact as well as noncontact methods. Photoalignment, which is a light-induced, noncontact method, optimized the experiments in Zhou’s research, and for which she and her team utilized the Nikon Eclipse microscope.

“My research falls between material science and polymers science,” says Zhou. “I’m in the subgroup that studies liquid crystal polymers to create next-generation smart plastics.”

Smart plastics, as Zhou goes on to relate, are polymers that are responsive to stimuli such as light, heat, electricity, or magnetic fields.

“In our case, we are interested in the photochemistry side of material chemistry, so we want to use light as the stimulus to create a certain dynamic in these liquid crystal polymers,” Zhou continues. “Specifically, we are trying to photo-align these liquid crystals at the molecular level because they have this interesting property between solid, in which they are pretty rigid, and liquid, when they have more mobility. But in that liquid state, they are too disordered, by which I mean that they cannot organize themselves. Visualizing and measuring these levels of order is why we needed Nikon’s Eclipse LV100ND microscope.”

Unique applications call for flexible equipment

The Eclipse LV100ND can perform polarized analysis under episcopic and diascopic light. Polarization in electromagnetic waves (such as light) refers to the oscillation of electric and magnetic fields, which are always perpendicular to one another.

Using a polarized optical microscope such as the Eclipse LV100ND permits optical anisotropic analysis, which, in reference to liquid crystal polymers, helps characterize the relative molecular alignment and ordering (or disordering, as the case may be) of the materials being tested.

“To help us see the alignment of these materials, Nikon’s Eclipse microscope is really powerful,” says Zhou. “In photochemistry, we use light to achieve alignment. With this microscope, we can introduce light sources in different directions, either from the bottom or from the top, and we have the ability to play with how the lights are shining on the sample.”

These optional light sources are contained within the episcopic illuminator available with the Eclipse LV100ND. This illuminator functions as both a light source and a beamsplitter and can use filters and aperture controls to enable brightfield or darkfield analysis.

“We can build our own analysis systems with this microscope,” says Zhou. “For example, we have the control to see certain wavelengths of light coming through in different directions.”

“When I visited the lab to see what Joy and her team were doing with the Eclipse LV100ND, I was impressed,” says King. “It was probably the most complex setup I’ve ever seen, with a lot of add-ons and special features.”

That flexibility and wide range of features found in this microscope has proven to be of the utmost importance to Zhou’s research, given the time and efficiency bottlenecks from alternative methods to achieve and inspect photoalignment of these liquid crystal polymers.

“I’ve learned from my professors that in research of this kind, there are two big things to think about,” says Zhou. “The first consideration regards the fundamental science we are seeking to discover. Then, we want to ensure that we’re using the right technique or characterization tool that can be applied to our research in different areas. That’s why we highlight the use of Nikon’s Eclipse microscope for monitoring liquid crystal alignment. Other methods can be slower but are also our complementary to the microscope. In fact, we do use some of these methods in our own research as well. What makes the setup of the microscope convenient, and somewhat different from other methods, is that it allows us to monitor the liquid crystal polymer alignment in real time.

“Using the Nikon Eclipse microscope and a camera setup, I can see the start of alignment in as fast as 80 seconds, which is really fast,” Zhou continues. “Using wide-angle X-ray scattering, meanwhile, while we can see the alignment data right after the data is collected, without further data analysis, those data would be just raw data or a generated plot that might give us a qualitative information about the alignment. It is not in situ because we don’t take X-ray measurements during photoalignment, but afterwards.”

Applying lessons while pushing the envelope

In all successful relationships, each party teaches the other. In this vein, as much as the researchers at The University of Texas at Austin Chemistry Department have learned about the functionality of the Eclipse LV100ND from the expert team at Nikon, they’ve also opened the eyes of Nikon application engineers about the full potential of this remarkable industrial microscope.

“I see a lot of people using the same microscope that Joy is using,” says Matt King, Nikon’s District Sales Manager for Industrial Microscopes/Measuring Instruments. “Many of those partners are in the semiconductor industry, and they typically use the diascopic and episcopic light sources for inspection. But the Chemistry Department at the University of Texas at Austin is really pushing the envelope with this application. In this partnership, we’ve helped them get the most of the Eclipse LV100ND, and they’ve taken it even further and showed us all it can do.”

As King mentions, those in the semiconductor sector are keen to utilize some of the Eclipse LV100ND’s inspection attributes being explored by Zhou and her colleagues in the University of Texas–Austin Chemistry Department. These microscope uses can also be applied in sectors such as medical devices or electronic components. Any application involving the inspection of parts and materials at the sub-micron level will benefit from the flexibility of this tool.

Meanwhile, Joy Zhou is looking forward to more research and new ways to use the Eclipse LV100ND.

“This first photoalignment project in our group was completed and the paper published last year,” Zhou says. “Here in my second year, I’m doing a new project, trying to learn how to make my own liquid crystal polymers. I’ll use Nikon’s Eclipse LV100ND to characterize the properties of these new polymers.”

As demonstrated by the work that Joy Zhou is doing at The University of Texas at Austin, academic research plays a vital role in fostering industrial advancement. So-called “pure science” relentlessly asks questions such as the true properties of liquid crystal polymers in various states, and the tools of the trade must adapt and grow to help researchers find the answers. Consequently, Nikon sees how the Eclipse LV100ND can offer improved edge detection, flaw inspection, and materials analysis for various industrial clients. It’s colloquially known as a “win-win” and left this Nikon client excited for the future.

“It’s all about combining components,” Zhou says, anticipating future projects. “Not for the sake of complexity, but just to do cooler research!”

1 J. Zhou, J. Seo, Y. Wu, C.P. Ambulo, Z.M. Marsh, K.N.Lee, N.P. Godman, and Z.A. Page, Adv. Funct. Mater. 2023, 33, 2308828.