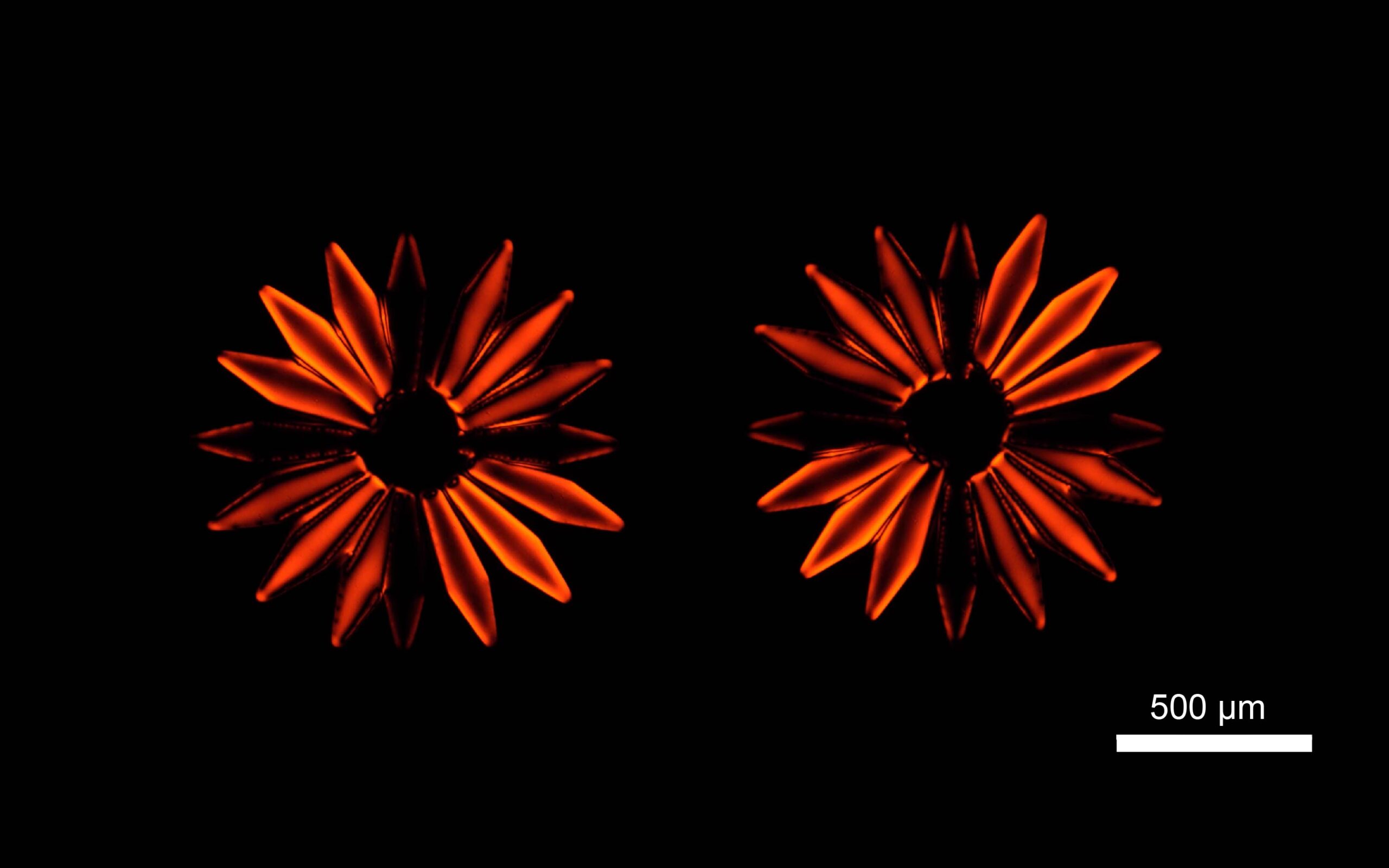

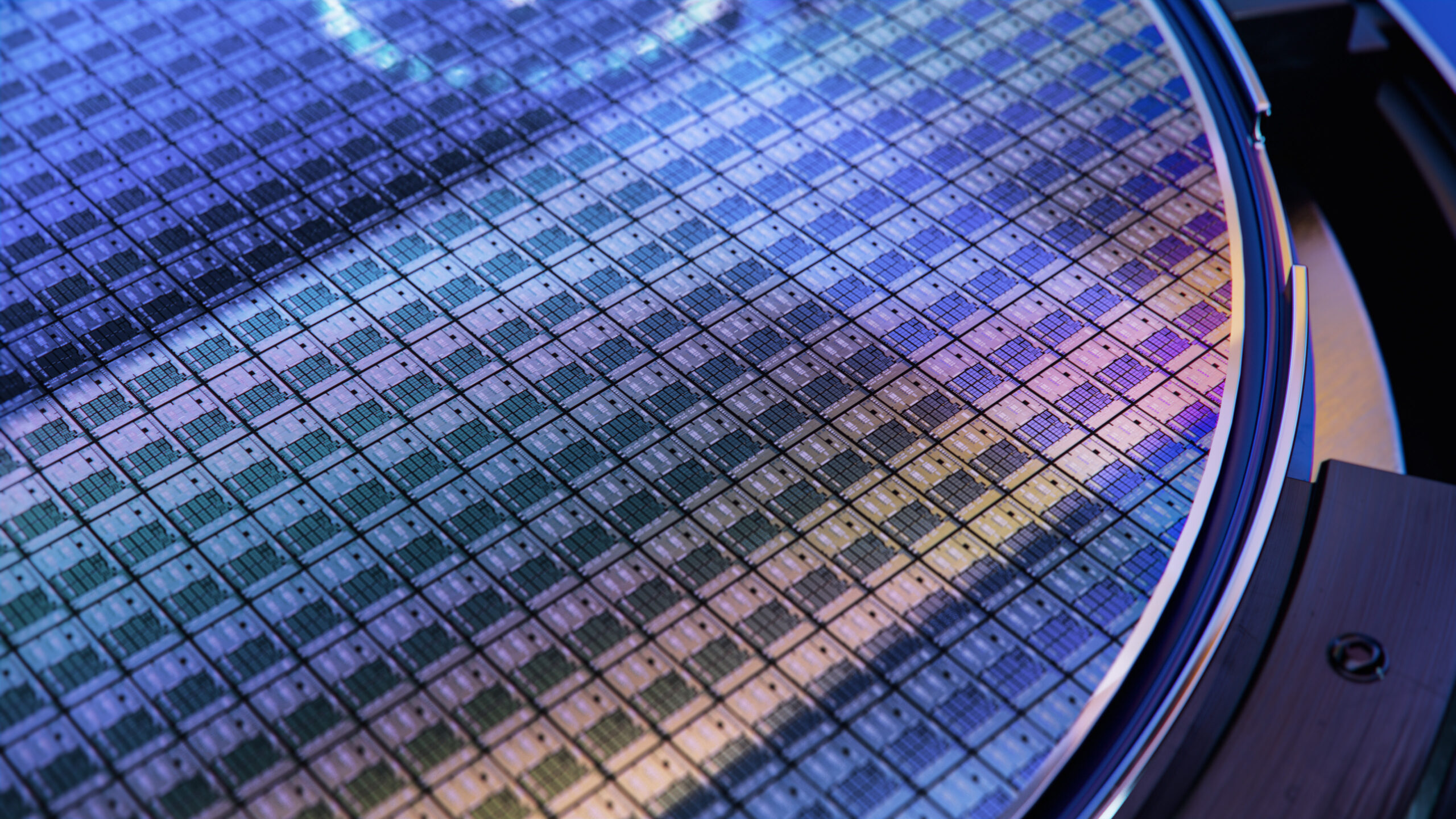

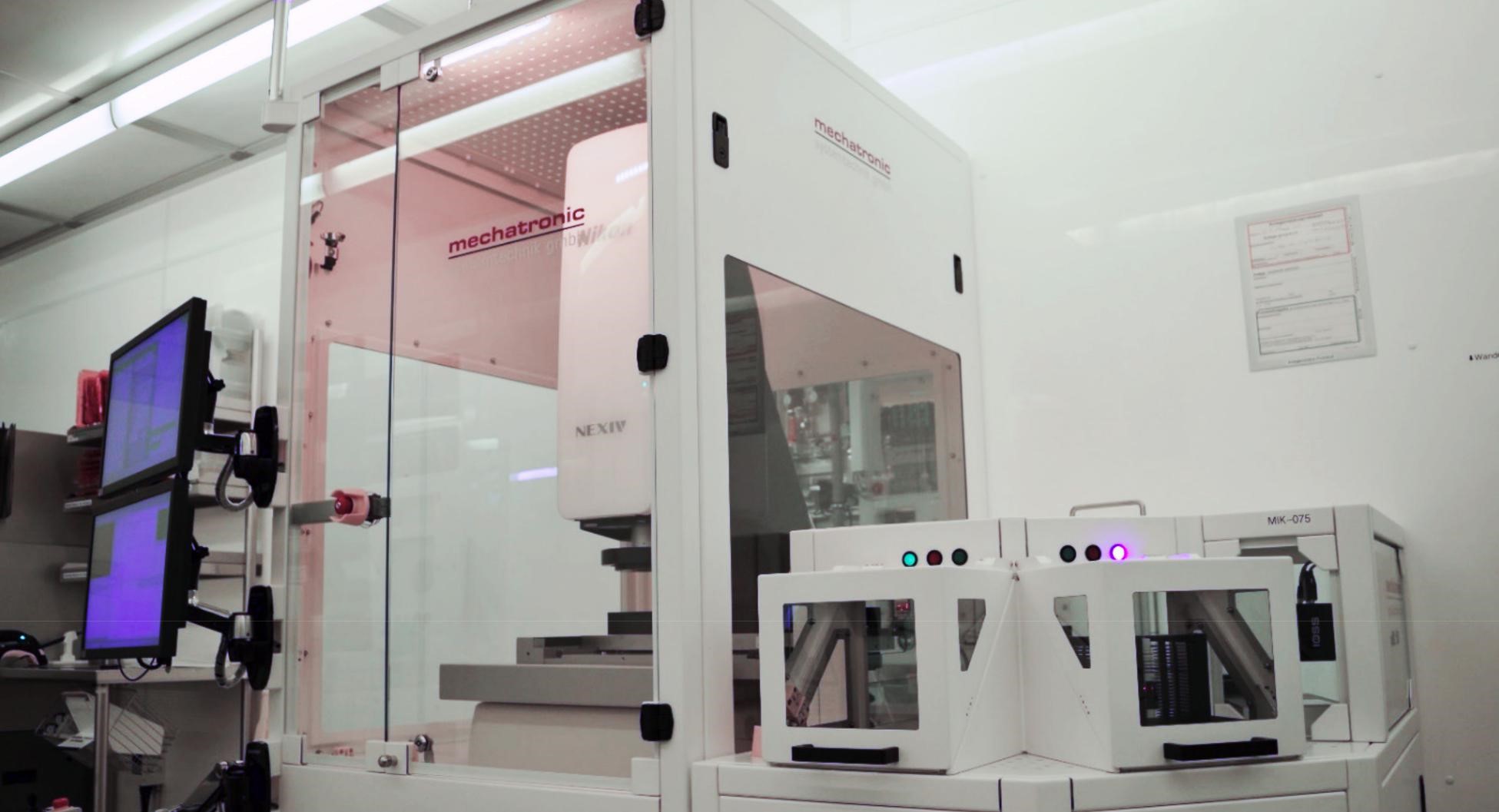

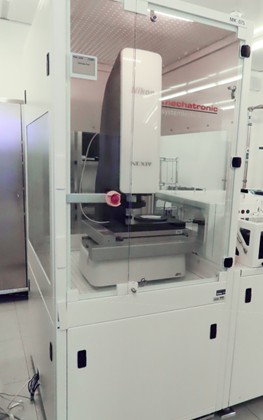

Semikron Elektronik GmbH, headquartered in Nuremberg, is one of the world’s leading manufacturers of power electronic components such as integrated circuits, discrete semiconductors, transistors, diodes, thyristors and power supplies in the medium power range from approx. 1 kW to 10 MW. These are used in a wide variety of industrial sectors, from electric and hybrid vehicles and industrial drives to wind and solar power generation and the railway industry. Until recently, the company used several optical microscopes from Nikon Metrology to survey and inspect 6-inch semiconductor wafers for quality assurance and production optimization.  Nikon Metrology NEXIV VMZ-R3020, automated with an mWL150 Single-Arm Wafer Handling Tool. This is the first system to be installed in a cleanroom at the Nuremberg plant of Semikron Elektronik GmbH. In July 2017, the electronics company decided to upgrade its own non-contact inspection capabilities and acquired the first fully automatic measurement and inspection system for 6-inch wafers from the same supplier. This consists of the combination of a NEXIV VMZ-R3020 CNC video measuring system including AutoMeasure software and a mWL-150 Wafer Handling Tool with double loadport for recording up to 50 wafers. The robot unit picks up the wafer to be measured from the wafer cassette, then places it on the prealigner for alignment and ID number recognition and then transports it to the vacuum table of the NEXIV systems for actual measurement. After completion of the measurement, the wafer is transported back to the wafer cassette and the collected measured values and additional information are automatically transferred to the central IT system for evaluation. Dr. Klaus Mümmler, Process Engineer in the Photolithography Department at Semikron, explains: “The microfabrication of miniature samples for the production of circuits on our 6-inch wafers creates structures in the micrometer range. “The overall performance of the devices convinced us, in addition to the long and good cooperation with Nikon Metrology” Dr. Klaus Mümmler, Process Engineer in the Photolithography Department at Semikron

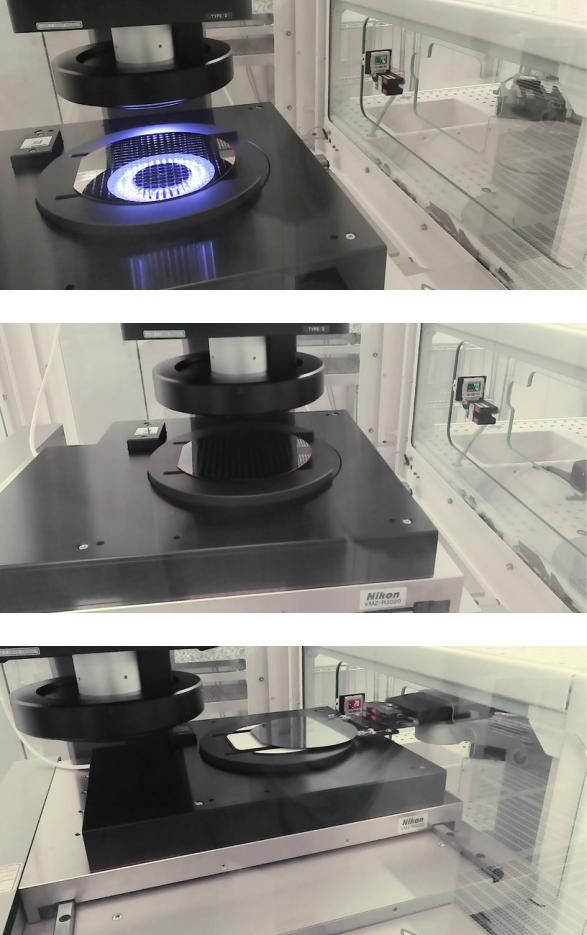

Nikon Metrology NEXIV VMZ-R3020, automated with an mWL150 Single-Arm Wafer Handling Tool. This is the first system to be installed in a cleanroom at the Nuremberg plant of Semikron Elektronik GmbH. In July 2017, the electronics company decided to upgrade its own non-contact inspection capabilities and acquired the first fully automatic measurement and inspection system for 6-inch wafers from the same supplier. This consists of the combination of a NEXIV VMZ-R3020 CNC video measuring system including AutoMeasure software and a mWL-150 Wafer Handling Tool with double loadport for recording up to 50 wafers. The robot unit picks up the wafer to be measured from the wafer cassette, then places it on the prealigner for alignment and ID number recognition and then transports it to the vacuum table of the NEXIV systems for actual measurement. After completion of the measurement, the wafer is transported back to the wafer cassette and the collected measured values and additional information are automatically transferred to the central IT system for evaluation. Dr. Klaus Mümmler, Process Engineer in the Photolithography Department at Semikron, explains: “The microfabrication of miniature samples for the production of circuits on our 6-inch wafers creates structures in the micrometer range. “The overall performance of the devices convinced us, in addition to the long and good cooperation with Nikon Metrology” Dr. Klaus Mümmler, Process Engineer in the Photolithography Department at Semikron  It was time-consuming to test and measure such small features with manual light microscopes. The reproducibility of the process was low, the traceability of the results was not ideal and there was no way to archive them without doing it by hand.” In order to remedy these shortcomings and to increase the number of inspections in order to enable a better statistical evaluation, he and his colleague, Marco Kleber the Process Engineer, decided to install the Nikon Metrology NEXIV VMZ-R3020 after testing a number of alternative measuring instruments on the market. An important decision factor for the Nikon solution was the crosslinkability of the wafer handling automation software with the software for measurement and reporting. The exact table control in combination with the efficient image stitching function of the AutoMeasure software also proved to be particularly advantageous. Dr. Mümmler added: “The overall performance of the devices convinced us, in addition to the long and good cooperation with Nikon Metrology, which made the decision easier for us. The installation of the system went smoothly and the training went without problems. Since then, we have installed a second system with a further developed double-arm handling tool.” Through automation, the measurement accuracy and repeatability have been greatly improved and the results are interpreted faster and easier. As a result, any shift in the parameters of the manufacturing process can be detected and corrected with greater precision in order to achieve a higher quality of the components. In addition, the direct link between data collection and its evaluation has significantly improved traceability compared to manual measurement. Today, Semikron employs 3,000 people in 24 offices worldwide, with production facilities in Germany, Brazil, China, France, India, Italy, Slovakia and the USA. Their innovative power electronic products enable customers to develop smaller, more energy-efficient systems, which in turn helps to reduce the global consumption of fossil fuels. Nikon Metrology is pleased to support Semikron and its customers in achieving this goal. ABOUT NEXIV VMZ-R3020 SYSTEM AT SEMIKRON The CNC video measurement system has 15x zoom optics that deliver high resolution at high magnification. Episcopic and diascopic LED lighting, as well as double 8-segment LED ring lighting with three different angles, offer great flexibility to optimize the lighting of the samples. With XY travels of 300 x 200 mm, the NEXIV System can measure any small components, such as mechanical components and molded parts. However, the inspection of highly integrated electronics, be they printed circuit boards or wafers, is one of the core applications of the device.

It was time-consuming to test and measure such small features with manual light microscopes. The reproducibility of the process was low, the traceability of the results was not ideal and there was no way to archive them without doing it by hand.” In order to remedy these shortcomings and to increase the number of inspections in order to enable a better statistical evaluation, he and his colleague, Marco Kleber the Process Engineer, decided to install the Nikon Metrology NEXIV VMZ-R3020 after testing a number of alternative measuring instruments on the market. An important decision factor for the Nikon solution was the crosslinkability of the wafer handling automation software with the software for measurement and reporting. The exact table control in combination with the efficient image stitching function of the AutoMeasure software also proved to be particularly advantageous. Dr. Mümmler added: “The overall performance of the devices convinced us, in addition to the long and good cooperation with Nikon Metrology, which made the decision easier for us. The installation of the system went smoothly and the training went without problems. Since then, we have installed a second system with a further developed double-arm handling tool.” Through automation, the measurement accuracy and repeatability have been greatly improved and the results are interpreted faster and easier. As a result, any shift in the parameters of the manufacturing process can be detected and corrected with greater precision in order to achieve a higher quality of the components. In addition, the direct link between data collection and its evaluation has significantly improved traceability compared to manual measurement. Today, Semikron employs 3,000 people in 24 offices worldwide, with production facilities in Germany, Brazil, China, France, India, Italy, Slovakia and the USA. Their innovative power electronic products enable customers to develop smaller, more energy-efficient systems, which in turn helps to reduce the global consumption of fossil fuels. Nikon Metrology is pleased to support Semikron and its customers in achieving this goal. ABOUT NEXIV VMZ-R3020 SYSTEM AT SEMIKRON The CNC video measurement system has 15x zoom optics that deliver high resolution at high magnification. Episcopic and diascopic LED lighting, as well as double 8-segment LED ring lighting with three different angles, offer great flexibility to optimize the lighting of the samples. With XY travels of 300 x 200 mm, the NEXIV System can measure any small components, such as mechanical components and molded parts. However, the inspection of highly integrated electronics, be they printed circuit boards or wafers, is one of the core applications of the device.  The NEXIV VMZ-R3020 System is able to measure and evaluate features with image processing with high precision. In addition, surfaces can also be detected by means of TTL laser scan to obtain topography data for profile evaluation or for roughness measurements. Of particular note are the large working distance, the wide field of view and the high numerical aperture for excellent resolution. The measurement accuracy is increased by high-resolution (0.01 micrometer) linear encoders for feedback of the axis positions to the controller.

The NEXIV VMZ-R3020 System is able to measure and evaluate features with image processing with high precision. In addition, surfaces can also be detected by means of TTL laser scan to obtain topography data for profile evaluation or for roughness measurements. Of particular note are the large working distance, the wide field of view and the high numerical aperture for excellent resolution. The measurement accuracy is increased by high-resolution (0.01 micrometer) linear encoders for feedback of the axis positions to the controller.  The programmable AutoMeasure software platform is the ideal tool to record and evaluate the data collected by image processing. Features include interactive measurement and learning assistants, a CAD interface, the ability to perform shape analysis, and data management tools. Integration with programs for profile form evaluation, 3D surface analysis and reporting. The graphical user interface offers the user the possibility to use standard layouts or to adapt them individually. These include advanced features of the programming editor, the live image window and control over the lighting conditions. Users can perform simple routine operations with a limited layout or use a fully equipped layout to create simple or complex programs. The WL150-2d Wafer Handling Tool with the two-arm robot is an automation unit of cleanroom class 5 according to ISO EN 14 644-1 (a better class is optionally available), which is designed for the autonomous loading and unloading of 6-inch wafers from cassettes for inspection. The Wafer Handling Tool is equipped with one or two needle end effectors, two cassette stations with scanners, a pre-aligner, a needle test station and a touch screen. On request, two different wafer sizes can also be processed in one system. For the handling of larger wafers, larger wafer handling tools (mWL200/300) are also available for the inspection of 8- or 12- inch wafers. The NEXIV VMZ-R3020 has now been succeeded by the NEXIV VMZ-S3020.

The programmable AutoMeasure software platform is the ideal tool to record and evaluate the data collected by image processing. Features include interactive measurement and learning assistants, a CAD interface, the ability to perform shape analysis, and data management tools. Integration with programs for profile form evaluation, 3D surface analysis and reporting. The graphical user interface offers the user the possibility to use standard layouts or to adapt them individually. These include advanced features of the programming editor, the live image window and control over the lighting conditions. Users can perform simple routine operations with a limited layout or use a fully equipped layout to create simple or complex programs. The WL150-2d Wafer Handling Tool with the two-arm robot is an automation unit of cleanroom class 5 according to ISO EN 14 644-1 (a better class is optionally available), which is designed for the autonomous loading and unloading of 6-inch wafers from cassettes for inspection. The Wafer Handling Tool is equipped with one or two needle end effectors, two cassette stations with scanners, a pre-aligner, a needle test station and a touch screen. On request, two different wafer sizes can also be processed in one system. For the handling of larger wafers, larger wafer handling tools (mWL200/300) are also available for the inspection of 8- or 12- inch wafers. The NEXIV VMZ-R3020 has now been succeeded by the NEXIV VMZ-S3020.

Products and promotions may differ based on your selected region.