Today we speak to Sergei Kolobov, Applications Engineer within the X-ray Business Unit, about his responsibilities and his expertise on the XT V systems range.

Hi Sergei, could you please tell us what are your individual responsibilities within Nikon Metrology?

In my role as an Applications Engineer, I provide technical guidance by identifying customers’ specific requirements and helping to find the best possible solution for specific applications. During the pre-sales process, I am mainly involved in performing benchmarks, assisting in technical proposals and demonstrating possible solutions. While during the post-sales process I am educating personnel through product and application training on the X-ray systems. Also, the development and implementation of customer-specific solutions fit under the post-sales process.

What are the best parts of your job?

The variety of the industries and state-of-the-art technologies that our customers are involved in means that no customers or their applications are the same. Every solution has to be tailored to fit specific needs and that requires a creative approach with the large set of tools available. It is always nice to see how people are experiencing a eureka moment after they have gained insights into the inside of their products and prototypes during the demo.

Any anecdote that you would like to share with our readers?

I remember a fun tests set up on an XT V system that involved scanning a ‘scratch-off lottery’ ticket. The idea was to find out if the ticket had a jackpot without removing the scratch layer. Unfortunately, the contrast of the ink under the metallic scratch layer was insufficient to conclude if the ticket had winning symbols on it. Too bad, otherwise I would have been rich!

Another fun fact: sometimes it happens that a package comes in the office without a name on it, so it is not unusual to find colleagues peeking inside packages with the X-ray system to find out what is inside and to whom it could be addressed.

Could you please tell us what benefits the customers can expect from the XT V systems range?

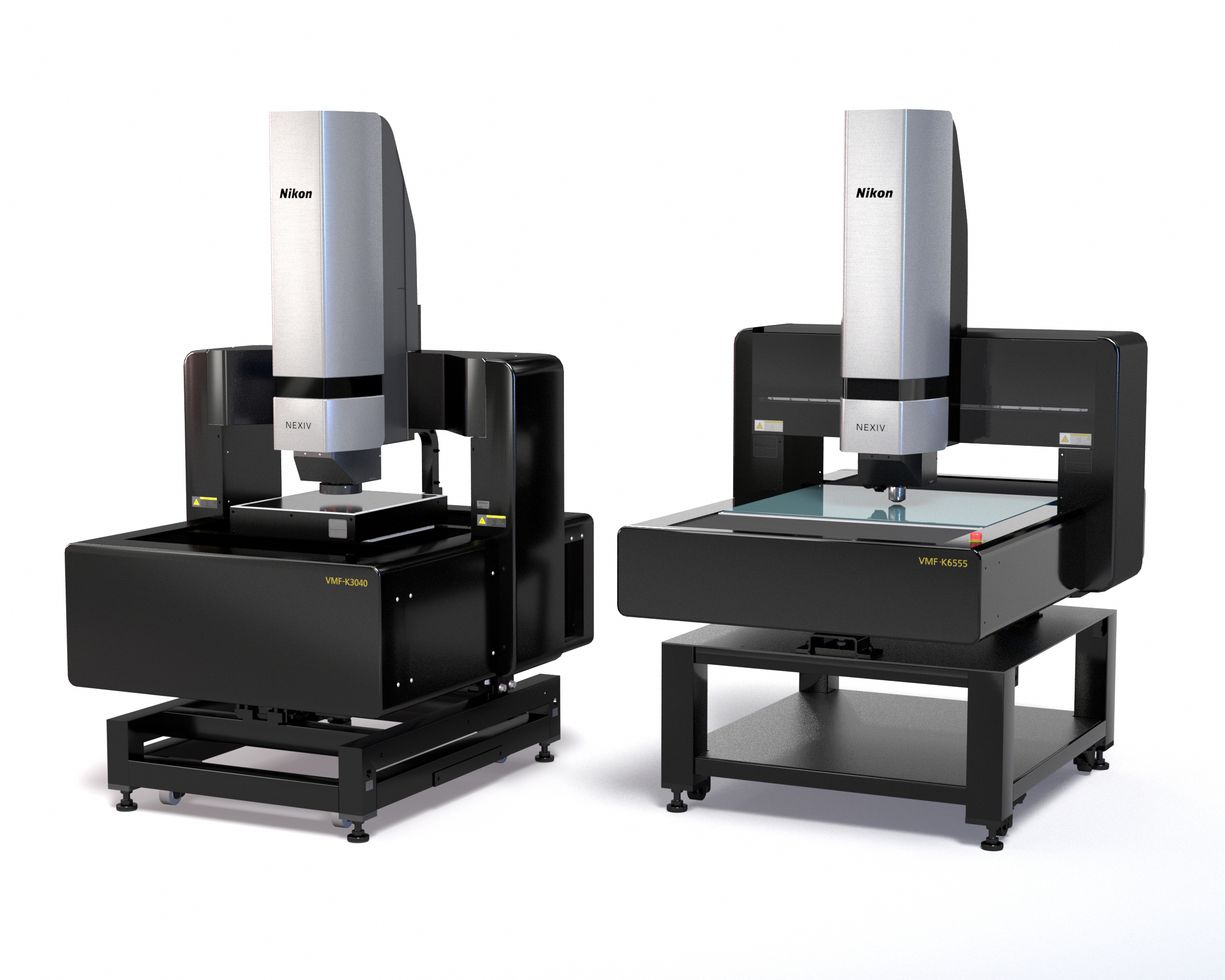

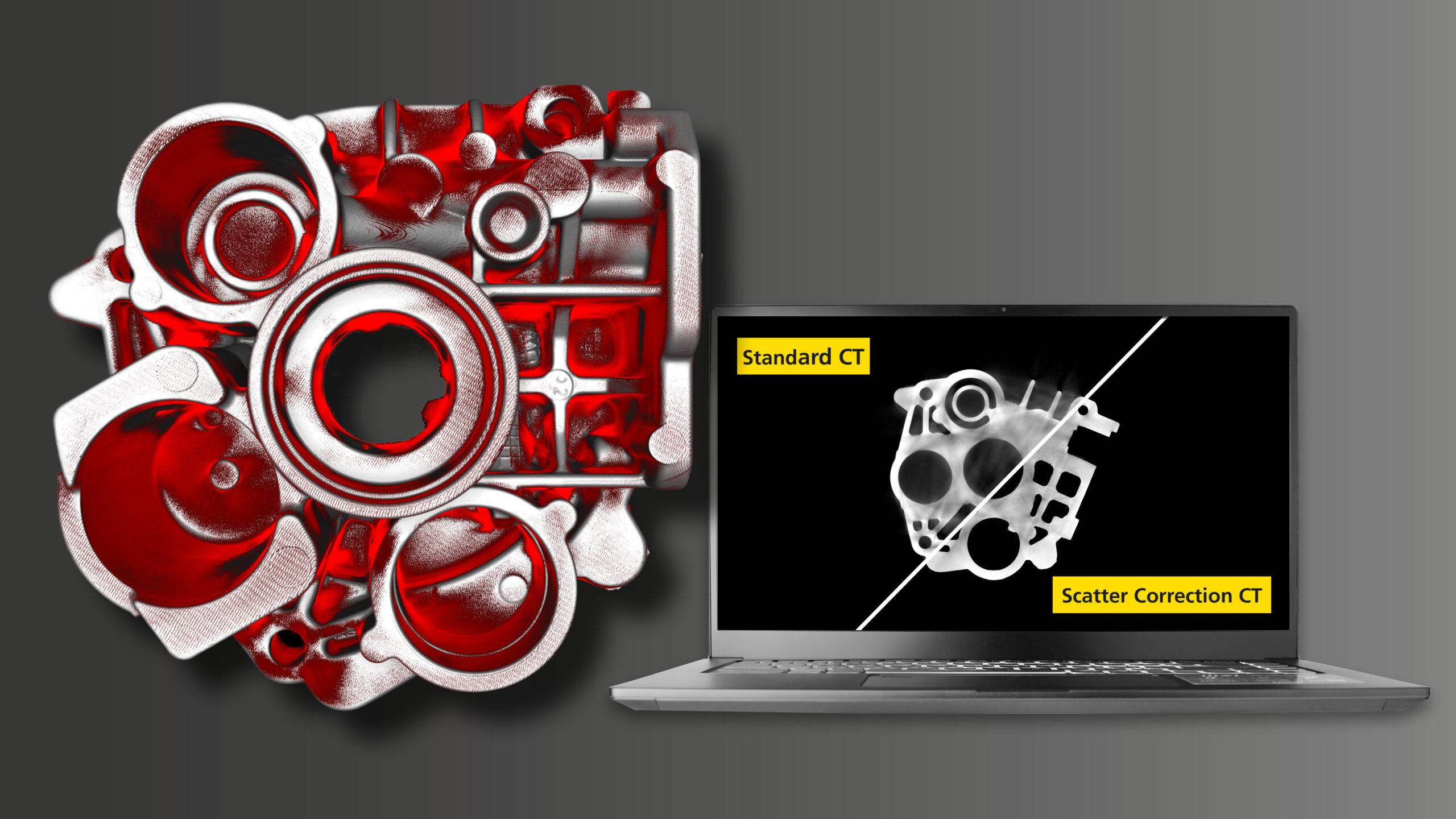

A huge inspection area in combination with a collision-free geometry allows for intuitive 2D radiographic inspection. The number of image analysis tools and the ability to easily create automated routines makes the inspection process very fast. 20W of X-ray target power in combination with a spot size measured in microns and extremely high geometric magnification virtually drills down to the core of the problem by visualizing the tiniest of defects deeply embedded within the part.

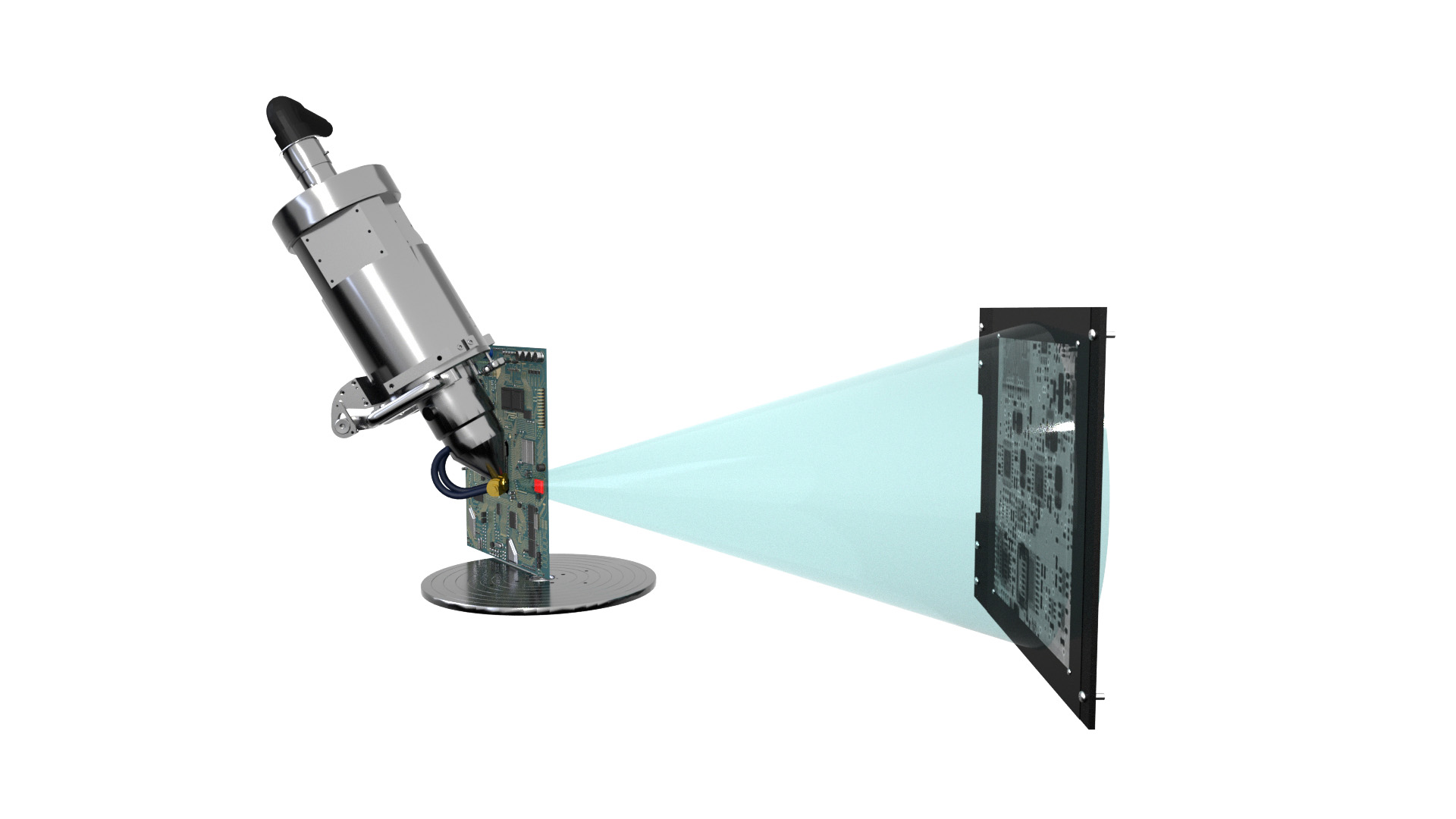

It is a simple system with several sophisticated components that are seamlessly integrated into a single stand-alone unit. For example, a patented X-ray source design with an integrated high voltage generator that can be moved from side to side is the main reason why an XT V system has such a small footprint. That allows for such a system to be installed through the office door on the 6th floor of an R&D center or anywhere on the shopfloor by occupying a minimum of production space.

What sectors & industries can benefit from using the Nikon Metrology XT V systems?

XT V systems can be deployed across a very wide range of industries: it can be a very valuable tool for in-depth first article inspection or reverse-engineering projects for legacy or novel parts. The XT V system fits perfectly within PCB manufacturing plants because of a relatively flat inspection volume, but it is certainly not the only field of use. As long as the sample can fit into the cabinet, it can be inspected. The modularity of the system enables it to fit customers needs today and future challenges.

As a Nikon Metrology expert, what is your favourite system feature & why?

X.Tract, which is our commercial name for Laminography. That is a scanning technique that allows customers to virtually slice an object at any given position, independent of objects geometry, in a non-destructive way. A quick X.Tract scan provides a very high-quality sliced view of the part. When radiography is already at the limit of imaging a certain feature due to obstruction of different elements, X.Tract can segment a specific slice and visualize these features that would not otherwise be visible. If one would X-ray a book, with Radiography all of the pages would be seen at once. While X.Tract will enable you to read that book page by page by slicing it through.