To celebrate the start of the Formula 1 motor racing season, Dr. Andrew Mathers (X-ray CT Project Manager) scanned a 1:32 scale, 3D printed, 2022 Formula 1 car with a Nikon XT H 225 ST 2x X-ray CT system.

The continued growth of additive manufacturing (AM), which includes 3D printing, spans a considerable number of industries and applications (including automotive, aerospace, medical, dental, renewable energy and military) but the one thing they all have in common is the need to evaluate the accuracy and quality of the AM process and its products. Nikon X-ray CT systems enable us to non-destructively visualise the micro-structure of AM parts, assess conformity with their design, dimensionally inspect their geometry, uncover defects (porosity, inclusions and cracks) and even simulate how they will perform under real world stresses and strains.

Over the past 10 years, the adoption of AM has also grown substantially within motor racing, with the introduction of literally hundreds of plastic, carbon fibre, resin or metal based AM components. The ability to rapidly manufacture prototypes, test their performance, modify their design as required and repeat this part of the design cycle, is extremely beneficial in the iterative, innovation led, ultra-competitive world of F1.

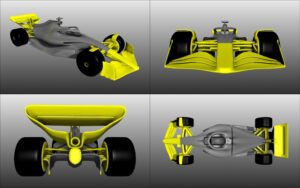

3D renderings from multiple viewpoints showing the 12 individual CAD files used to perform the 3D printing, exhibited in Nikon brand colours and aligned to the global CAD model of the car

The first panel of four 3D renderings shows all 12 individual CAD files, used for the 3D printing, aligned to the global CAD model and exhibited in Nikon brand colours.

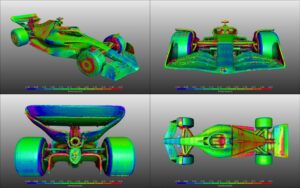

3D renderings from multiple viewpoints showing the individual X-ray CT scan volumes for each 3D printed component, aligned to their parent CAD files and evaluated via nominal actual comparison against the global CAD model of the car.

To visualise the accuracy of the 3D printing process the individual X-ray CT scan volumes for each 3D printed component, were aligned to their parent CAD files and evaluated via nominal actual comparison. The results of this are colourfully illustrated in the second panel of renderings, with the use of the Nominal/Actual Comparison Module in Volume Graphics.

3D printing of the 12 individual car components (×2 front wheels; ×2 rear wheels; ×2 front suspension; ×2 rear suspension; front monocoque; rear monocoque; front and rear wings) was carried out by James Finch (X-ray CT Applications Engineer) using a Creality Ender 5 Pro with a 0.4 mm diameter brass nozzle, coupled with an eSun PLA+ filament (diameter 1.75 ±0.03 mm). Components were printed using polyactic acid (PLA) at 1:38 scale (456 scale factor: 1/456xp viewport scale) with a layer resolution of 0.1 mm and a combined total print time of 14 hours 49 minutes.

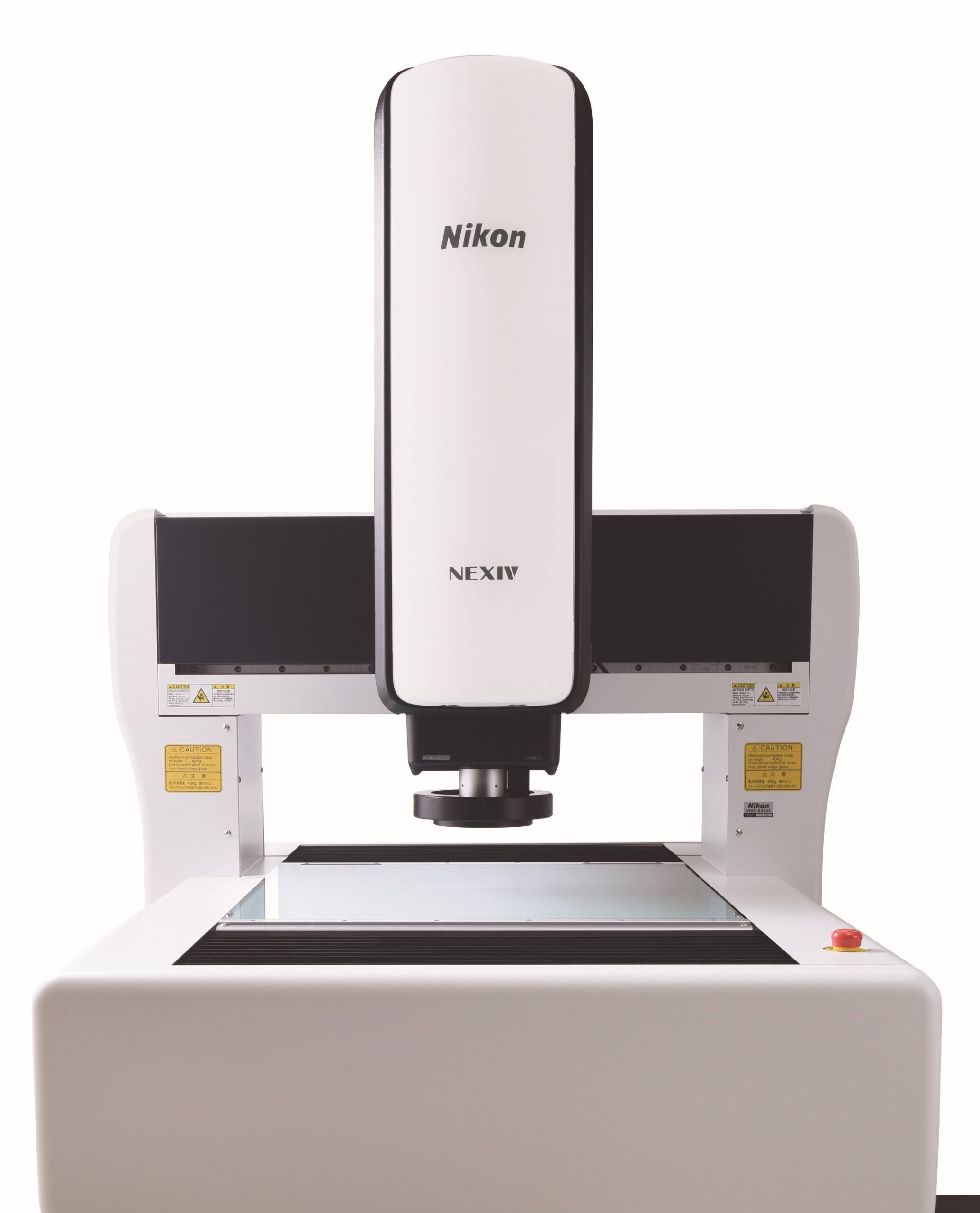

X-ray CT scans of the 3D printed components were acquired at 44 µm voxel resolution and 130 W, using a Nikon XT H 225 ST 2x. This system was equipped with Nikon’s own 225 kV, 450 W Rotating.Target 2.0 X-ray source, coupled with a Varex XRD 4343CT flat panel detector. For these scans the detector acquired 4476 projections (individual radiographs) at an exposure time of 354 ms.

X-ray CT data was reconstructed using a modified filtered back projection algorithm in Nikon CT Pro 3D and rendered in Volume Graphics StudioMax 3.5.