Nikon Metrology is already highly regarded for their range of Best in Class Industrial Stereo and Compound Microscopes. However, are you aware that the Eclipse LV range is fully modular in design and so can be configured to overcome many of the problems that a traditional Microscope solution may have?

There are times when a standard outfit Microscope simply does not fit exactly what the user is looking to do. This is where the ability to create your own “Bespoke Microscopy solution” becomes necessary.

Nikon’s Eclipse LV range is designed to be modular and enable extremely variable configurations in a set up allow you to build a solution that is right for your own needs.

Below are two examples of options available from Nikon Metrology, so do talk with your own Territory Sales Manager about your applications as you will discover there are as many configuration solutions as there are challenges to overcome.

My sample does not have a polished or even a flat surface and so I cannot get an objective into position to view any specific area that I am interested in.

The problem: Shall we think of a sample which is so uneven in nature that a traditional objective cannot be positioned at the necessary height to focus on the artefact you wish to see

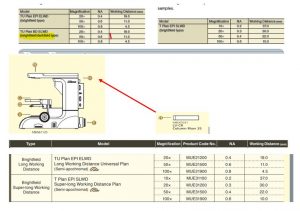

The Solution: In this case you may use our Extra-Long Working or Super-Long Working Distance Objectives which will provide you further space between the focus plane at the object surface and the actual bottom of the Objective lens. This is a much-used solution, and a wide range of these lenses are available for both Brightfield and Brightfield/ Darkfield contrast techniques. With our Super-Long working distance objectives it is possible to have up to a remarkable 37mm working distance between the object surface and the microscope, allowing excellent and safe clearance around the sample.

You may also choose to add a 30mm vertical Spacer (LV-CR Column Riser) to the top of the Microscope stand to accommodate taller than normal samples between the stage and objectives to be used.

NOTE: THE TABLE IS MISSING BF/DF LENSES. Here it is below as an extra and corrected content.

I have a big casting (engine block) on which I want to assess the quality of the metallurgical grain structure, and material integrity.

The Problem: It is not possible to put the large and heavy sample onto a standard stage or on any traditional upright microscope because the sample is too large and / or too heavy.

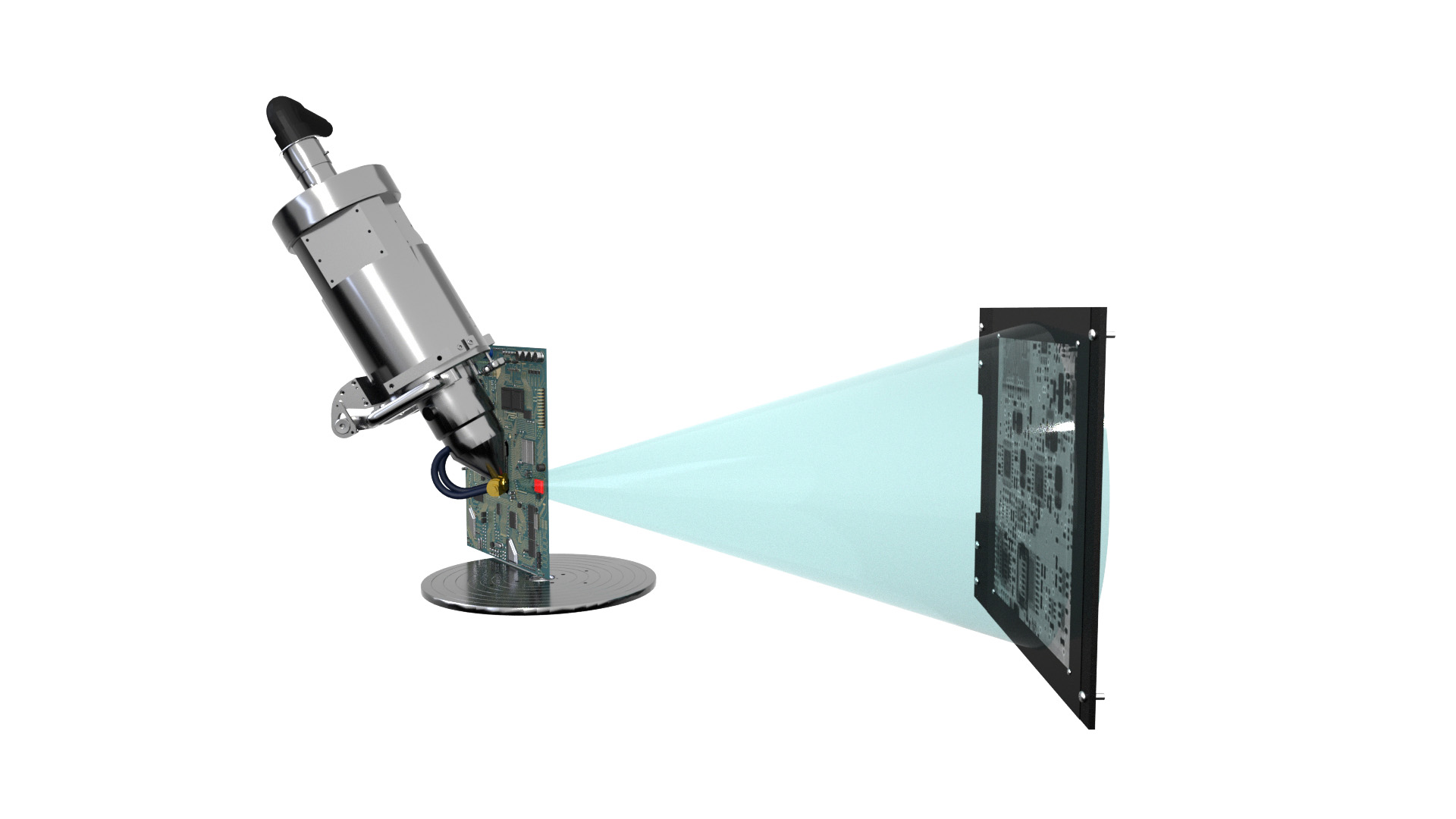

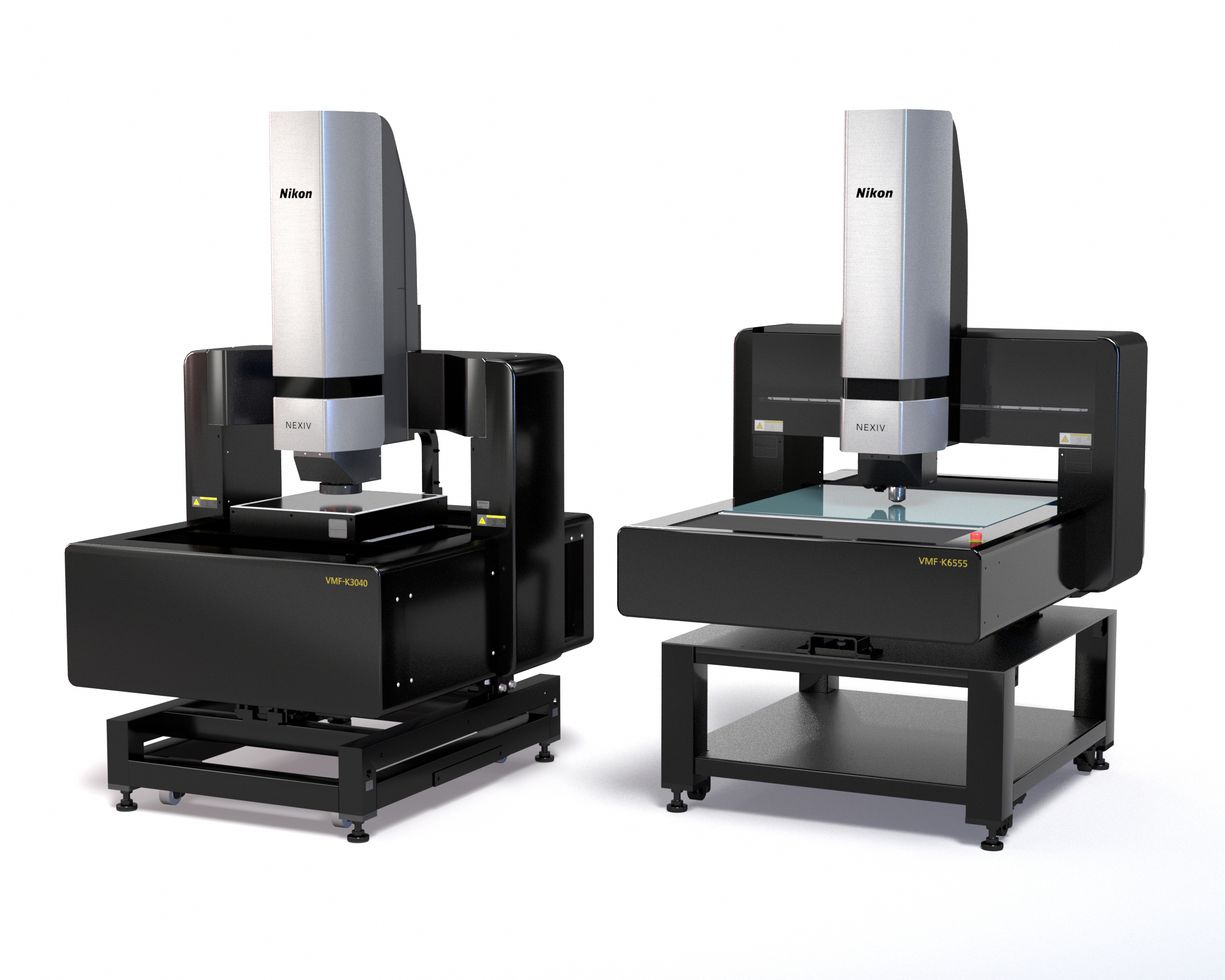

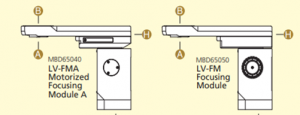

The Solution: In this case you may use the LV-FM or LV-FMA modules. These focus modules manual and motorised, can be fixed to the edge of a table or optical table / bread board to allow samples to be easily positioned beneath the objective nosepiece. The full variety of Nosepieces, Objectives, Illumination, optical contrast techniques and Eyepiece options can then be selected and fitted to fully suit the application requirement.

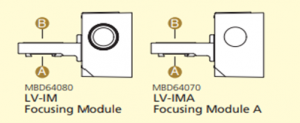

Alternatively, if you wish to use an even more unconventional microscope mount you can utilise the even more flexible LV-IM or LV-IMA options. These compact modules allow tools and dedicated oblique illumination very easy access in micro assembly and innovative raw material grading processes.

Nikon Metrology provides full details of the dimensions of these items so planning a bespoke set-up can easily be created as required by user.

The two examples above are designed to give you a flavour of what is possible and to illustrate how as a potential microscopy user you need not assume that a particular inspection or work process problem is impossible to solve.Please do contact your own local Nikon Metrology Territory Sales Manager and together we will be happy to assist you finding and defining a solution that really fits your needs.

Learn more and see full details of the Nikon LV range.