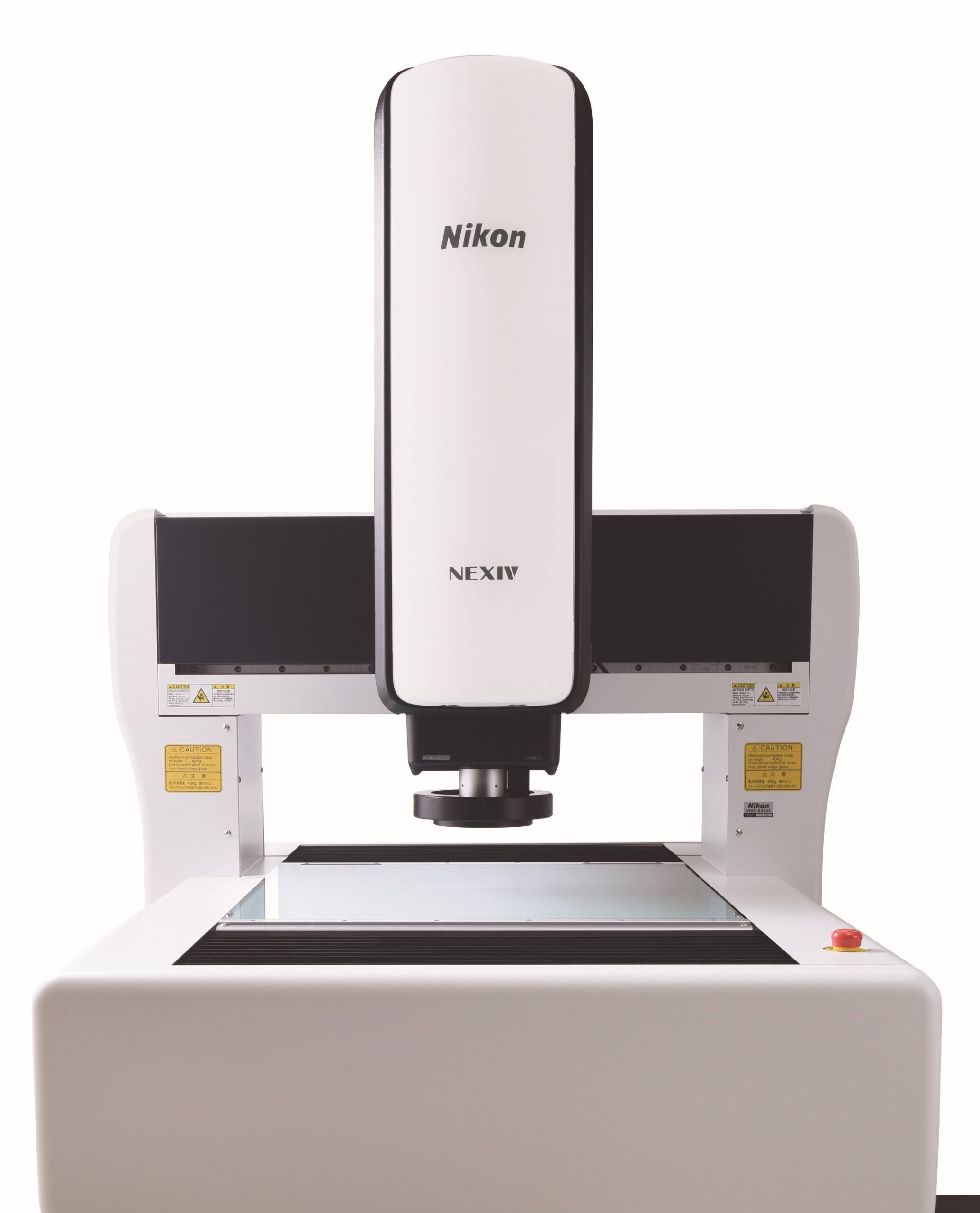

Our Microscope expert – Michael Hallewell has been working within Material Microscopy for over 15 years, so has a lot of expertise under his belt. We spoke to him about the Nikon Eclipse LV Microscope & how it is futureproofed for a huge range of tasks.

What is an LV Microscope?

The LV is Nikon’s Upright Microscope System for extensive optical analysis of materials.

The system offers massive flexibility on components because of the LV modularity. I call it ‘optical building blocks’ because it really isn’t an off the shelf solution, it is always adapted to my customer’s requirements. I want to make the microscope futureproof – to suit the needs for today & also for tomorrow… I know that sounds like ‘brochure talk’ but it is completely true!

What benefits can customers expect when using a Nikon Metrology Upright Microscopes Eclipse LV range?

There are many benefits from using a LV Microscope – such as the wide range of observation contrast methods, as well as providing a user with excellent optical performance – but most of all for me, it is extremely robust & versatile.

Another benefit of the LV is its modularity and upgradability. This in turn provides longevity for the microscope & allows customers to freely upgrade the system as & when their requirements change. Something else which is very important to note is we offer a lot of modular products which cannot only be integrated with our microscopes but also our software, NIS elements – together this greatly expands the ability to drive these systems & make the LV a complete solution.

A few examples of these modules which I can name from the Nikon Metrology Strategic Partner Programme are;

One of our partners offers a hot/cold stage which is a device which sits under a microscope lens & is very accurately temperature controlled. Why would you require this stage? Well, really it depends on a customer’s requirements & whether they would need the hot stage to be cool or warm. The stages can be set to different temperature levels – they go down to around -120 °C then right up to 1500 °C! These hot stages can be used for such a variety of different samples, such as crystals being viewed at specific temperatures & the effects can then be seen optically under the LV microscope in real time as it changes its form.

Fluorescent illumination is another module which can be added to the LV at any time. This is a device which can isolate & pick out coatings on a sample to investigate whether there is any UV active material present or not. A good example of this is – putting an UV resin labelled with a fluorescent marker (such as fluorescein) into a sample such as a cross section of steel (this is what we call a ‘micro crack’). The sample can be then be exposed to UV light from the microscope lens, which allows the customer to optically image very small cracks.

Adding motorisation to the LV microscope expands the capabilities & control functions particularly where X, Y control & Z axis focusing is required. I can often use the ability of the stage combined with software to create a large image overview & further utilise the high resolution of Nikon’s epic optics, then I (in basic terms) image stitch smaller areas into one large area on a sample, far beyond the field of view from the microscope lens.

What sectors & industries benefit from using the Nikon Eclipse LV Microscope range?

Because of its versatility, the Nikon LV can be welcomed into a wide range of industries. These include universities & research facilities to automotive & aerospace, metallurgy laboratories, manufacturing, paints & powders, semiconductor, chemical, pharmaceutical, medical devices, plastic & polymer, glass & ceramics, textile & paper & many, many more… I could keep going!

How does the Eclipse LV Microscope compare to other market competitors?

I have over 15 years of experience within Material Microscopy and I am also very familiar with the competitors’ products.

Firstly, for me the Nikon LV system boosts a very robust construction compared with competitor units. We have a lot of systems already out in the field in heavy industries where obviously they need a good quality product because of the harsh working environment. My LV’s are usually located in manufacturing or polishing labs, so as you can imagine they are not in a super clean-room setting.

Another thing to add is that I certainly have more flexibility with options compared to our competitors. Because the LV is a very versatile & modular microscope which obviously gives my customer a greater choice when needing to make their decision on what to buy.

As a Nikon Metrology expert for the Eclipse LV range, what is your favourite feature of the Eclipse LV & why?

It really is great quality microscope. I have no hesitation or worries about supplying the LV into any environment because I know it will do the job. It is a good faithful work horse! The already installed base we have today really speaks for itself.

Then, going back to its modularity – all customers have different requirements. Some like to look at a sample in its basic form, whilst others need the LV to be much more flexible in order to view the detail & range of their samples. I often get asked lots of weird & wonderful questions ‘I need to do this? What can I do? Is it possible?’ Every customer offers you something different to solve, even if it’s the same sector. So, I never assume it’s going to be the same application & same solution as last time, solutions are always unique! But that is where the flexibility really comes out using the LV.

Not everyone can sell a solution, but we are a solutions provider. Focused on helping & solving our customers problems with our products, often with 3rd party solutions to make that perfect fit.

It is crazy to think about how many products we all buy, use & wear every day which would have been under a microscope at some point. Door handles, windows, drawers, worktops, clothing – it’s all very interesting! That’s why I am so passionate about the LV, I know it offers excellent flexibility for all the requirements – it is our champion!

Get in touch to discuss your requirements or to simply request a free virtual demonstration. We’d love to help you find the right solution – click here to request more information.