Paul Lightowler, Product Manager for the APDIS Laser Radar, has been working at Nikon Metrology for many years. We have taken the time recently to speak with him about his responsibilities at Nikon, his experience and of course his favorite feature of the APDIS Laser Radar. Read his ‘Ask our Expert’ Interview below:

Could you please tell us your individual responsibilities within Nikon Metrology?

My roles and responsibilities cover most aspects of the APDIS Laser Radar product including development of promotional material with the Marketing department, definition of the development roadmap with the Engineering department, creation and maintenance of price lists and catalogues for the Sales departments, and development of best practice procedures and training for customers. So really, I act as an interface between the regions, the customers and the engineering and manufacturing teams.

What are the best parts of your job?

I really enjoy the varied roles that I have, allowing me to be involved in both the technical aspect and development direction of the Laser Radar, as well as the more creative side with the development and presentation of promotional material. Having responsibilities globally also means that I get to travel around the world (well, prior to current travel restrictions) and interact with a wide range of customers and colleagues.

Any anecdote that you would like to share with our readers?

In my previous role as an Applications Engineer for the Laser Radar, I have been involved in many on site demonstrations and customer measurements. At one measurement setup with a colleague, the customer was also doing some filming for internal promotion of the technology they were using, which included the Laser Radar measurements. The film crew asked us to do what we would normally do to perform a measurement so they could film the ‘highly technical and complex’ measurement taking place. They setup the camera, said go, and we moved the mouse to the ‘measure’ button, clicked it, then sat back and let the system automatically measure. I don’t think they realized quite how automated the Laser Radar measurement was. Not sure we made it into the final cut.

You have been highly involved the APDIS launch last year, what benefits can customers expect from using it?

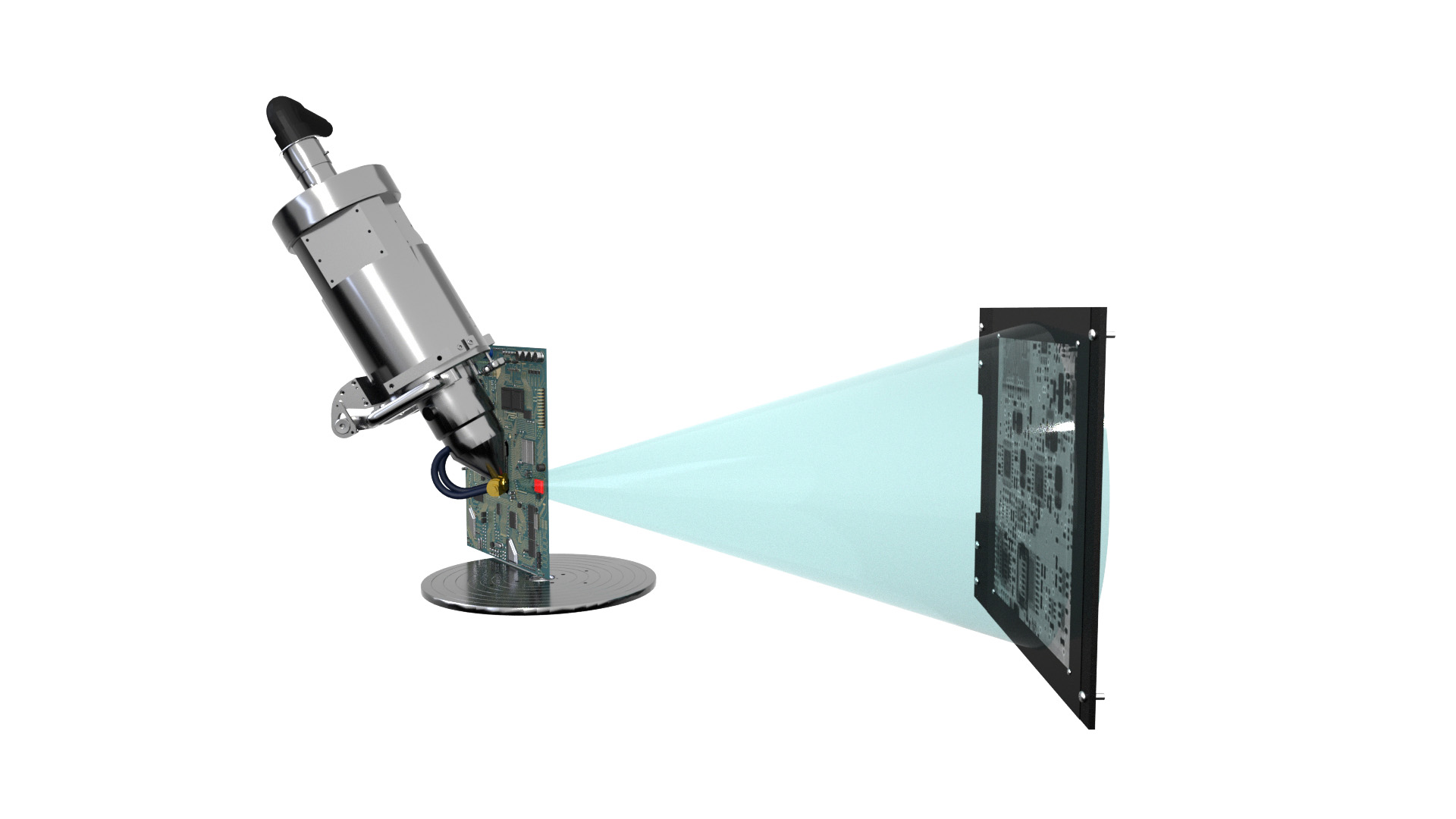

The APDIS launch was hugely successful, despite the issues we faced with performing a launch in a global lockdown. As a product it provides a huge leap forwards in our Laser Radar product offering, being a new design almost from the ground up allowing us to create a smaller, lighter and faster Laser Radar. Users will immediately notice the new look and smaller size allowing better handling and usability. Installation flexibility is also improved with standard mounting interfaces and improved robot adapters as well as a closer minimum range of 0.5m for more compact layouts. Additionally, our new HD camera and Nikon optics provide a much improved user experience with a clear view of what is being measured. Finally, productivity is greatly improved with our Enhanced system allowing up to double the measurement speed compared to the standard model. Overall, it is simply a much better system to work with.

What sectors & industries can benefit from using it?

The APDIS Laser Radar is suited to shop floor measurements of parts from the size of a car door, up to a full aircraft. All of this with high accuracy using non-contact laser technology over ranges up to 50m. Therefore a wide range of industries from Automotive, to Aerospace, to Energy, to Space, to heavy manufacturing can all benefit from the ability to automate the measurement process.

As a Nikon Metrology product expert for the APDIS Laser Radar, what is your favorite system feature of APDIS & why?

That’s a difficult one as there are a lot of new, existing and unique features that set the system apart, but for me, it’s the new HD camera. It really helps with the usability of the system to be able to clearly see what you are measuring both during setup and whilst running automatically. It may seem like a relatively minor thing, but as a former applications engineer, I like it. It also allows us to create good promotional videos, which is a bonus.