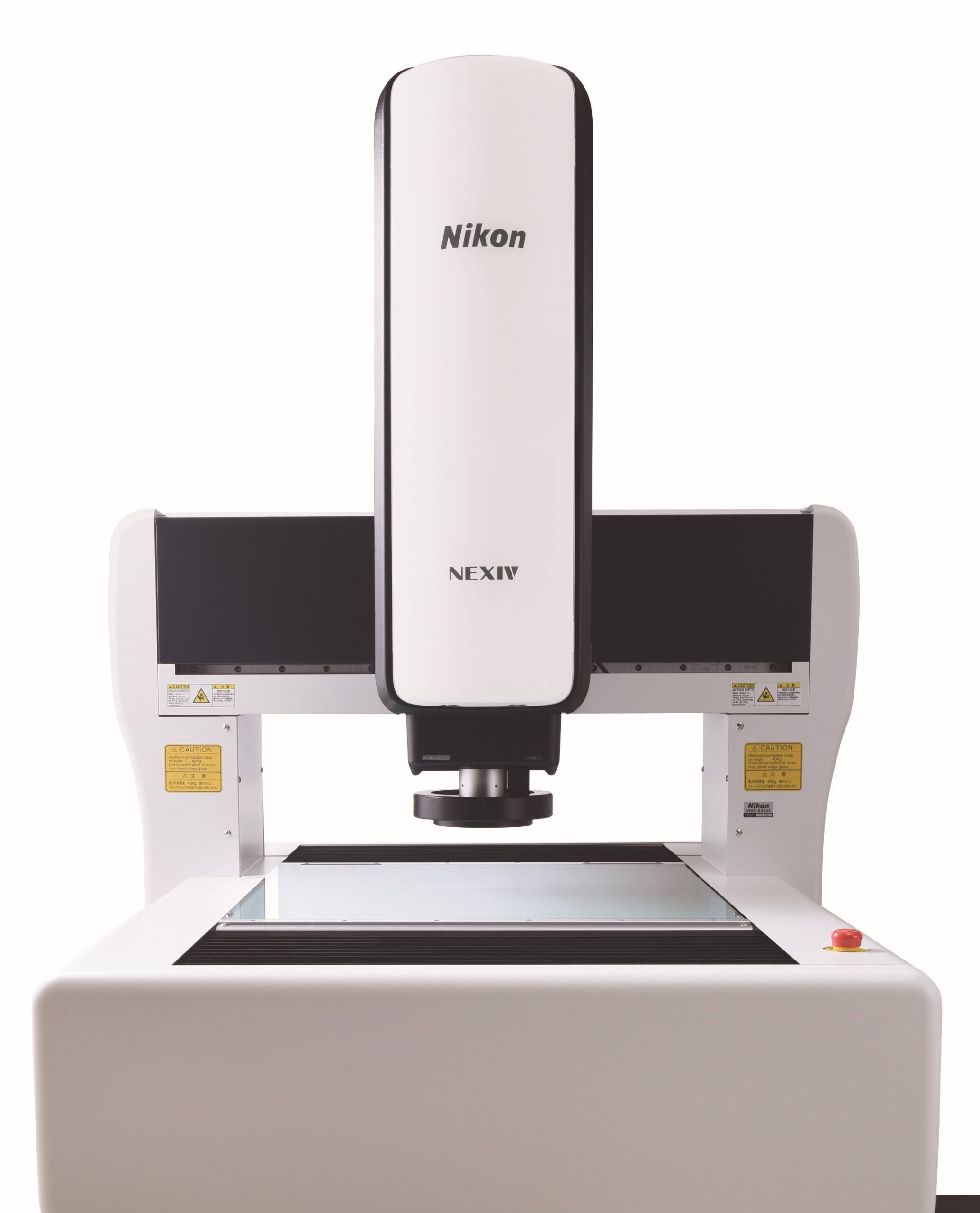

Nikon’s NEXIV series offers a wide range of products from entry-level bench tops to large extremely high specification systems. Designed to meetdemanding manufacturing requirements with automated measurements of mechanical parts, electronic devices, tools and moulds plus medical devices.

We spoke to our Nikon NEXIV expert Ulrich Beck, who is based in North Germany, about his experience working with the NEXIV series for over 20 years and what he thinks the newest member of the NEXIV family – the VMZ-S, brings to the table.

What is Nikon’s new NEXIV VMZ-S 3020 system?

The VMZ-S 3020 is the first newest member of the new NEXIV family. Nikon has been offering fully automatic image processing systems (NEXIV) for the high-precision optical measurement of components for a wide range of areas for over 25 years.

To talk about the most important elements of the VMZ-S 3020 system: I have to begin with the high-performance zoom optics with the versatile lighting options in LED technology. Secondly the precision measuring table made of cast steel with Nikon path measuring system and of course, the high-precision edge detection for measuring point recording with accuracy in the submicrometer range.

For measuring tasks in the Z-axis, the system has a TTL laser autofocus which measures directly through the optics on the surface. This works not only for single points but also in scanning mode with up to 1000 points per second and thus also enables surface analyses, for example for roughness measurements.

The software responsible for the measuring tasks comes from Nikon and brings all the functions necessary for the complete measurement solution, the operation is very intuitive and modern, which is super beneficial in learning the operation.

The system is designed for the measurement of individual parts but especially for fast and fully automatic series measurement for production monitoring.

What benefits can customers expect when using the new Nikon NEXIV VMZ-S?

A very important aspect in the development of the brand new VMZ-S series was to increase the measurement speed for higher throughput whilst maintaining the extremely high measurement accuracy of our existing NEXIV’s. Plus, to encourage the possibility to enable even untrained users to create measurement routines.

These requirements have been perfectly implemented by the consistent use of the fast USB-3 interfaces for communication and image transmission, as well as the increase in the acceleration of the measuring table enabling the measuring speed to be increased once again.

Thanks to the brand new “Teaching Support Measurement Tool”, simple measurement tasks can now be carried out very easily to help assist the operator.

Which industries benefit most from using a Nikon NEXIV VMZ-S?

Another advantage of using the new system in these sectors is the very high quality and resolution of the optics, which allows the measuring objects to be much smaller and yet the results are more precise.

Since the VMZ-S is a universal measuring system it is perfectly designed wherever a high measuring speed and precision are absolutely required, I am thinking for example, of the tool industry with high-precision cutting plates or also in medical technology with stents, implants or hearing aids – these industries absolutely benefit from our new system!

As a Nikon Metrology NEXIV expert, what is your favourite feature of the VMZ-S and why?

What always excites me is the simple and intuitive operation of our AutoMeasure software, especially the search function (PatMax). This software facilitates the measurement of several measuring objects without the use of complex and expensive devices for exact positioning. This unique function uses a saved pattern to find the actual position on the component and thus avoids interruptions in the measurement sequence, which usually require operator intervention.

Another highlight for me are the imaging functions with which deep-sharp images (EDF) and mosaic images (stitching) can easily be created. An old proverb already says, “A picture says more than a thousand words” – this applies to the VMZ-S as the images taken by the machine easily be inserted into reports. In addition, measurements can also be determined on the images afterwards.

How is the Nikon NEXIV VMZ-S compared to other competitors?

A major advantage of our NEXIV systems are the important and central assemblies, such as the complete optical system and the precision measurement stage including the encoder system all come from Nikon’s own production. The result is super high-resolution and brilliant images paired with high-precision measurement results.

Another advantage is the large selection of optical configurations always in conjunction with the Nikon’s epic high-speed zoom, which allows the system to be optimally tailored to the application.

The NEXIV systems really benefit from Nikon’s expertise in the field of manual optical measurement technology, microscopy and also in the field of “precision” systems (steppers), which offers a clear competitive advantage.

Get in touch to discuss your requirements or to simply request a free virtual demonstration. We’d love to help you find the right solution – click here to request more information.