Products and promotions may differ based on your selected region.

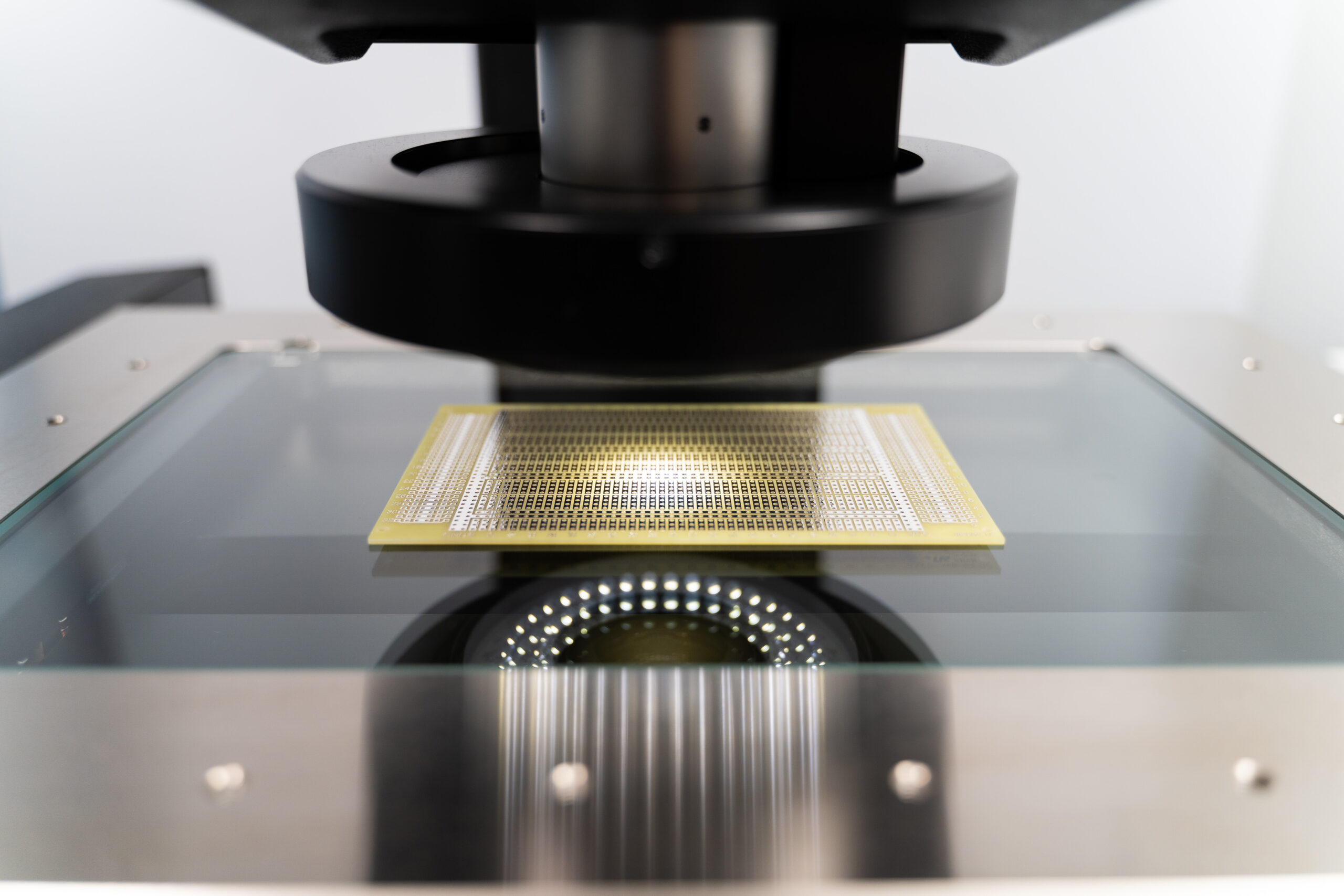

Automated EV Battery quality control with Video Measurement

Experience how NEXIV helps control production

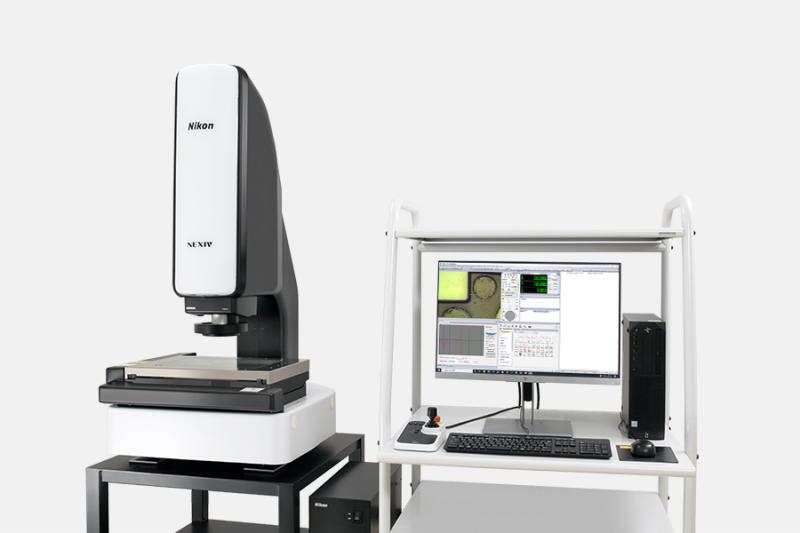

Nikon’s NEXIV video measurement system guarantees a stable and repeatable measurement of all necessary parameters in the EV battery inspection process. Easy-to-use systems combined with high quality hardware guarantee an early detection of process variations.

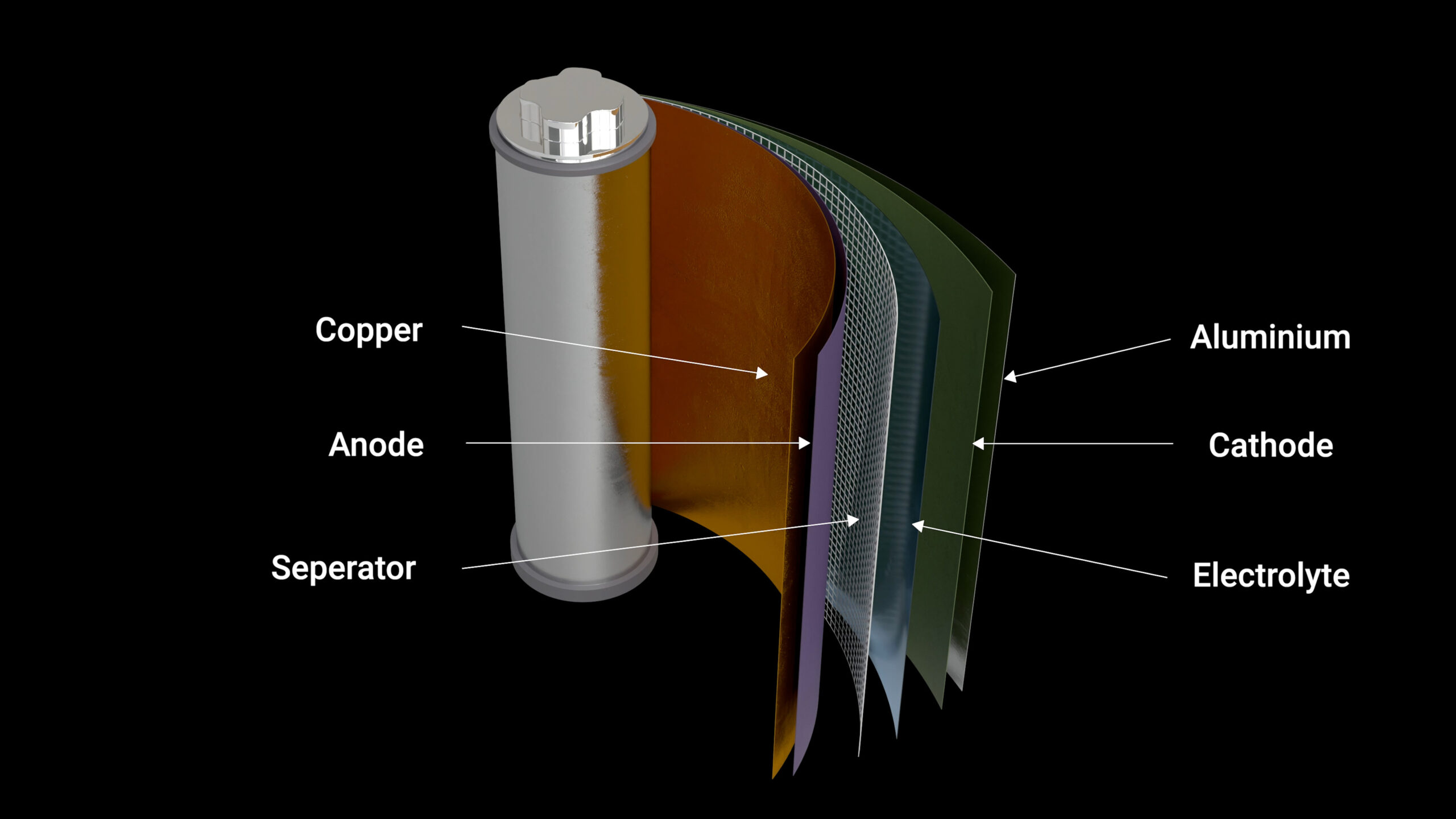

Within the critical and sensitive battery production, the right inspection process is essential.

Fast and precise dimension checks

Accurate production of battery foils remain a crucial part of the EV-Battery process. The NEXIV delivers fast and highly accurate measurement of the foils outer dimension, with automated control against nominal values and tolerances. The automated programs are quickly adjusted for various foil layouts and dimensions.

Full comparison to CAD drawings can be implemented to get a graphical display of potential errors and to detect systematical weaknesses in the production process.

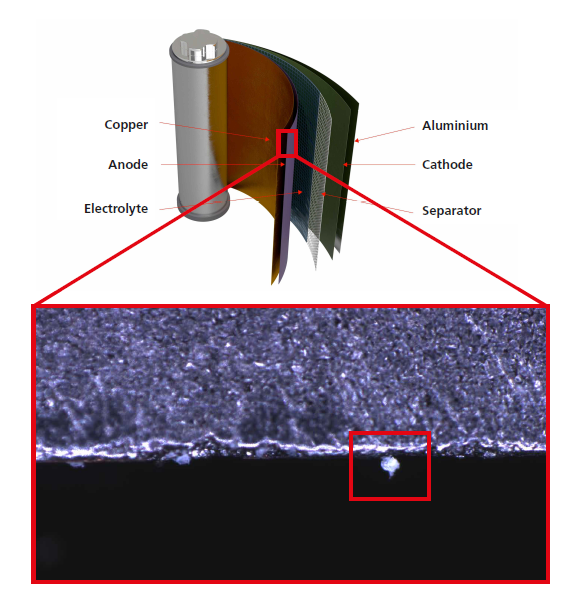

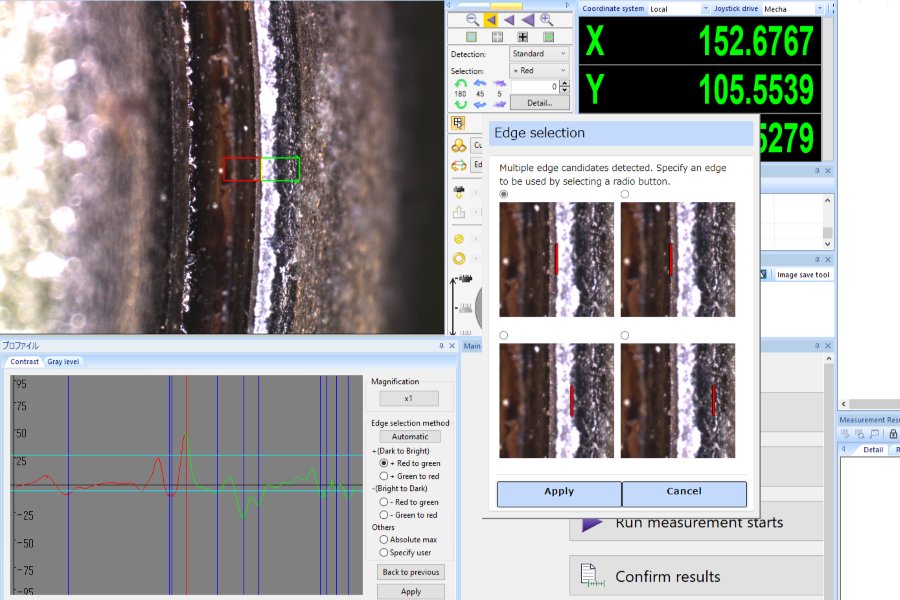

Chasing micrometres

When it comes to burrs or material thickness determinations, variations in micrometre size can be crucial for the end product and must therefore be detected accurately.

Our developed measurement routines automatically check for burrs with micrometre size and locate positions that exceed the tolerances.

Discover more about NEXIV

EV Battery Solutions with Nikon’s NEXIV Video Measuring Systems

Listen to our introduction webinar about EV Battery Measurement with the NEXIV.

Your NEXIV solution

The NEXIV series is available in different stage sizes allowing the measurement of different sample sizes. Ranging from 250 x 200 mm up to 650 x 550 mm we offer the correct size to measure your parts or load multiple parts to increase throughput and have less operator intervention.

Nikon’s world-renowned optics all come with a 5-stage optical zoom to guarantee a stable and accurate measurement of various sample features.

The NEXIV is available with different head types that generate a range of magnifications. In accordance with the measurement requirements, the correct optical head is selected, to guarantee measurements down to micrometer size.

NEXIV systems come with the easy-to-use AutoMeasure software, which let users quickly create their own measurement recipes. Additional software is available for further evaluation of the measurement results or saved images.

Schedule your test measurement

Does the NEXIV video measuring system sound like the ideal solution for your needs? Contact our team, and we will initiate the process so you can see the difference for yourself.

Frequently Asked Questions

We are happy to receive your samples and perform the tests according to your specifications. In our demo rooms we can find the best possible technical solution for your samples and develop the best possible measurement strategy.

Once we have received your sample for the test measurement, we need approximately 2 weeks to conclude the test measurement and to be ready to present you the results.

We are happy to schedule online meetings or live demos in one of our demo facilities in Düsseldorf (Germany), Derby (UK), or Lisses (France).

Once the system is installed in your facility, we provide customer specific training on hardware and software. On average, customers need two days to be able to create their own measurement programs.

Many manufacturers are using our NEXIV system to control their production process as best as possible. Over the years we developed a lot of fully automated applications for our various customers.

Contact our team

If you would like further details on EV battery control or more technical details of our NEXIV systems, our expert team will provide you with additional information and, if required, arrange an on-site visit.

Talk to us in detail about your project and our experts will advise you on the best inspection system to meet your requirements.

Please fill out the form and we will get in touch with you shortly.