Thank you all for joining our webinar about the latest advances in high-speed X-ray CT and how they enable reliable inspection of lithium-ion batteries on your shop floor.

Watch the recording and you will learn about the major roadblocks to achieving Quality 4.0 in lithium-ion battery production – and understand the latest solutions.

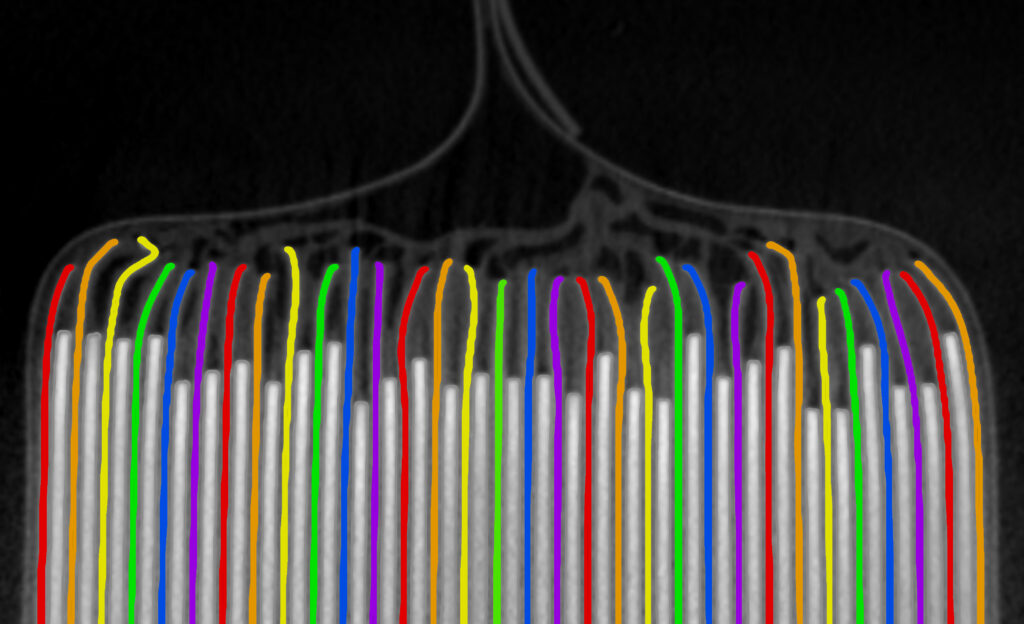

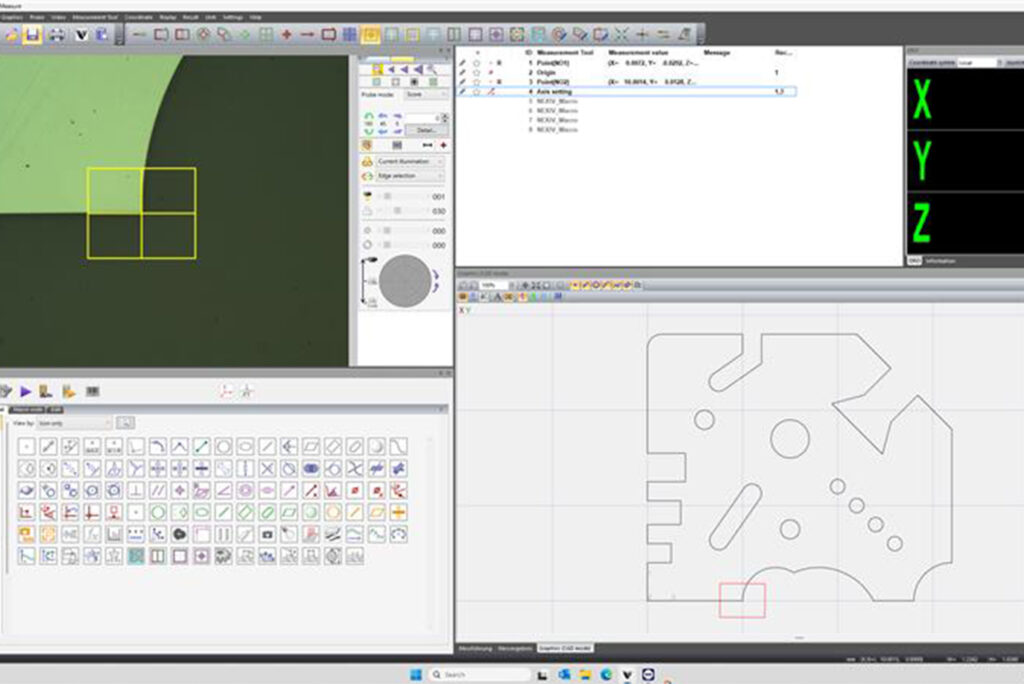

Traditionally, CT scanning is too slow for production environments – limiting manufacturers to 2D radiography, which can limit accuracy on complex assemblies, such as lithium-ion batteries. Our next-generation X-ray CT systems, cutting-edge AI, and proprietary X-ray-source and software technology, enable high-quality 3D CT scans fast enough for production lines. The result: zero-defect products, every time.

For maximum effectiveness in identifying internal and external dimensions, defects, and assembly issues, we want the best image quality, fast. To optimise production line parameters, it’s critical to achieve results as close to real-time as possible.

Nikon’s unique Rotating Target 2.0 and Half.Turn CT provides a substantial speed increase without compromising superior image quality. LiB.Overhang Analysis performs high-speed analysis with 3D data, powered by AI for automated inspection of lithium batteries. And the VOXLS 30 C 225, the latest addition to our new range of CT systems, integrates with shop floor processes seamlessly, with automation-ready hardware and Nikon Automation OPC UA Interface.

If you have missed this webinar, you find the recording here:

https://attendee.gotowebinar.com/recording/3504455153508967006