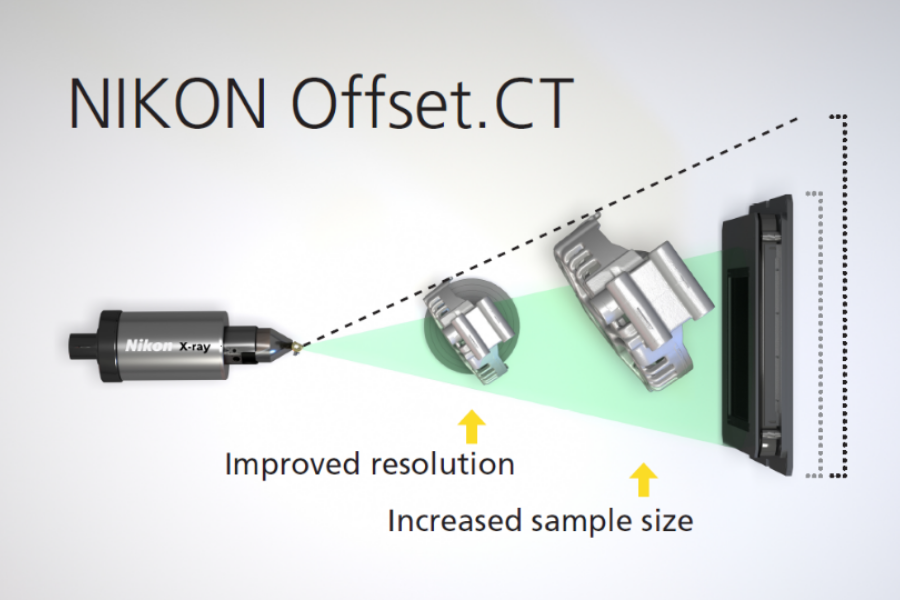

As technology has progressed in the automotive sector, we have seen once simple parts of vehicles become integrated with more technology and features. To showcase this, this month James Finch (X-ray Applications Engineer) scanned a heated steering wheel from a 2021 Vauxhall (Opel) Corsa.

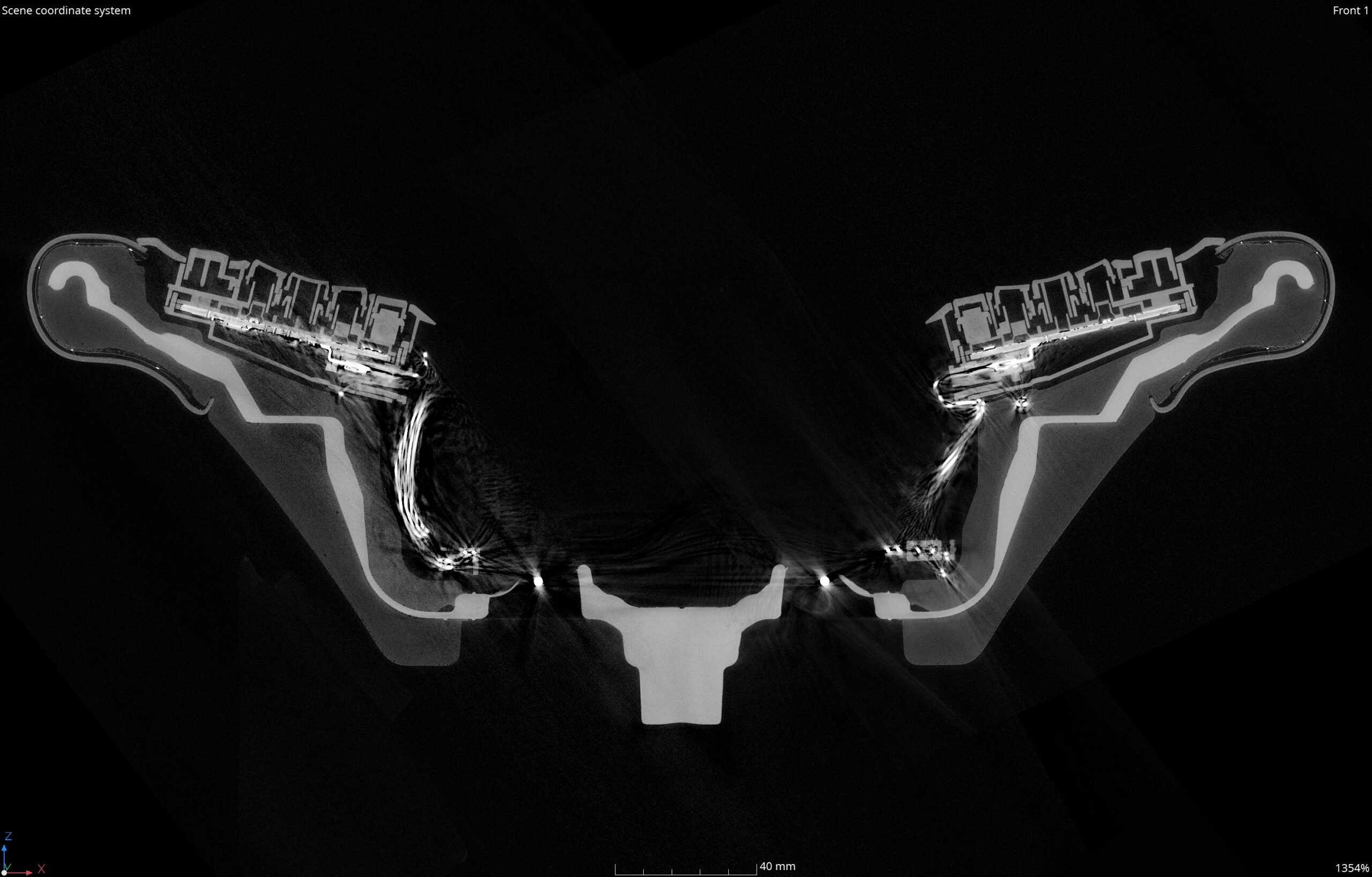

Figure 1: The composition of the heated steering wheel.

The X-ray CT data was acquired at a voxel resolution of 72μm using 210kV, a power of 90W and was acquired using a Nikon Large Envelope System (C2), which houses: a Nikon 225kV, and 450kV rotating micro-focus targets, as well as a Varian HPX-450kV mini-focus target; coupled with a Varex 4343N flat panel detector.

To scan the whole steering wheel, the 2-panel scan feature of the LES C2 was used which enabled the steering wheel to be scanned at a higher resolution than would otherwise be possible with a static panel. Between both panel-scans the detector acquired 34,684 projections at an exposure of 500ms.

Unusually the steering wheel was scanned using the Nikon 450kV micro-focus, which although typically used for high density or longer pathlength applications is still capable of achieving higher resolution data than would initially be expected.

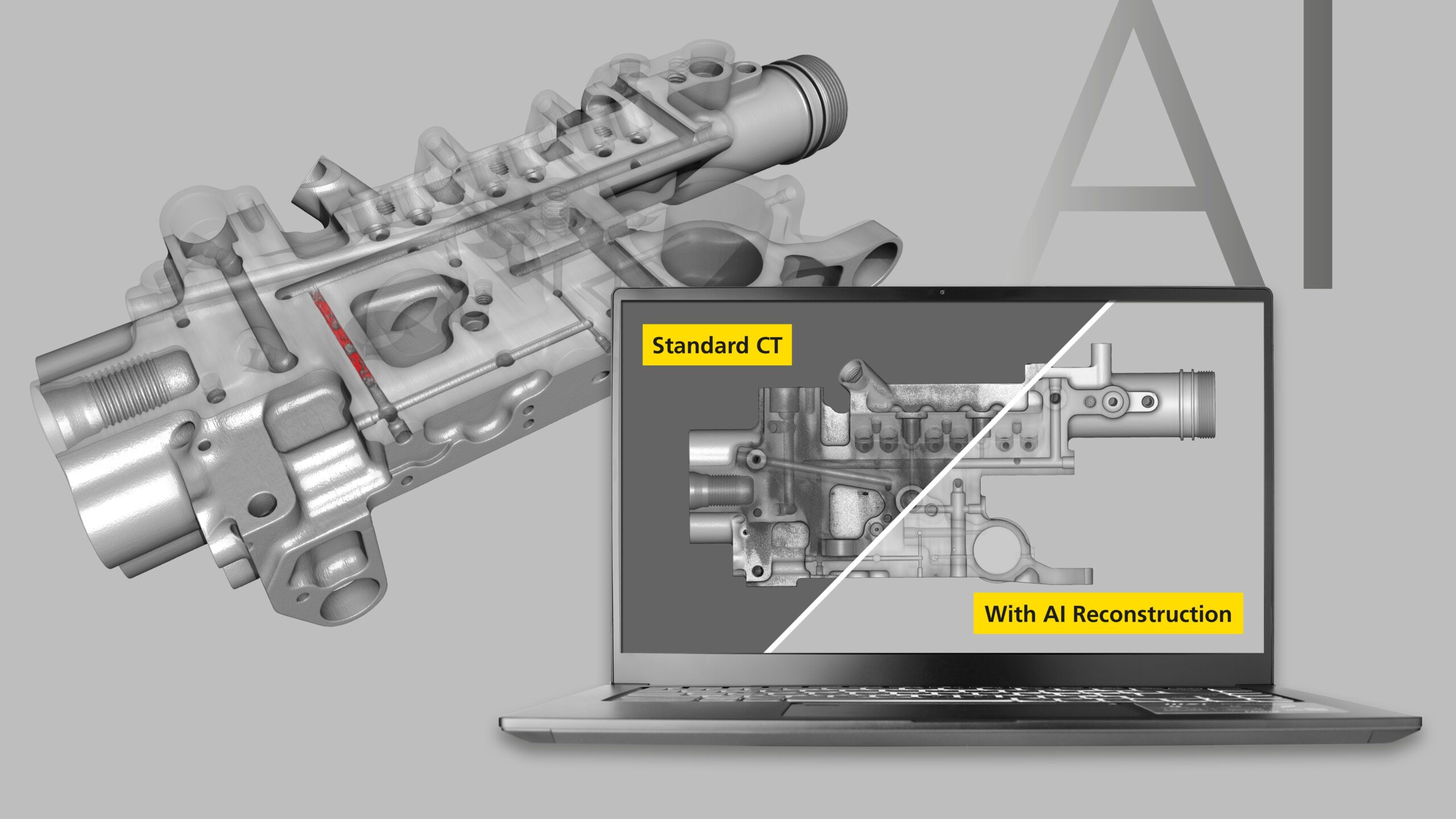

The data was reconstructed using a modified filtered back projection algorithm in Nikon CT Pro 3D, and then analysed in Volume Graphics Studio Max 3.5.

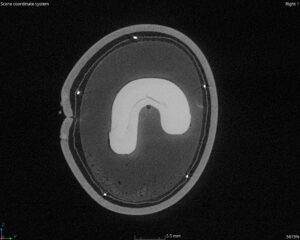

Due to the high dynamic range of the detector, and considering the x-ray attenuation of the different materials in the part when determining the scan parameters, both the high- and low-density parts of the steering wheel are visible in the data:

Figure 2: 2 D slices of the reconstructed dataset showing the different densities in situ.

Using a combination of surface determinations and region of interest manipulation we were able to segment the different components and identify some of the major features of the steering wheel.

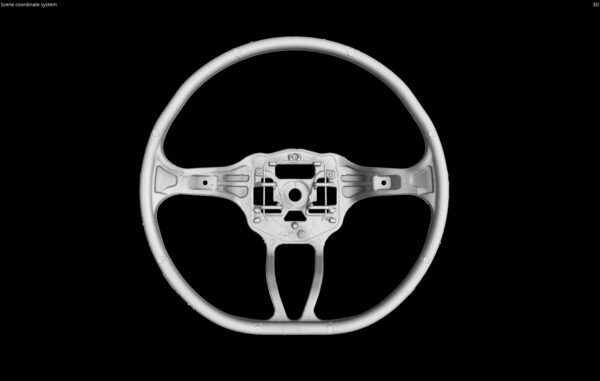

The first of these being the main structural metalwork within the wheel.

Figure 3: The metal structure of the wheel which constitutes most of the wheel’s form.

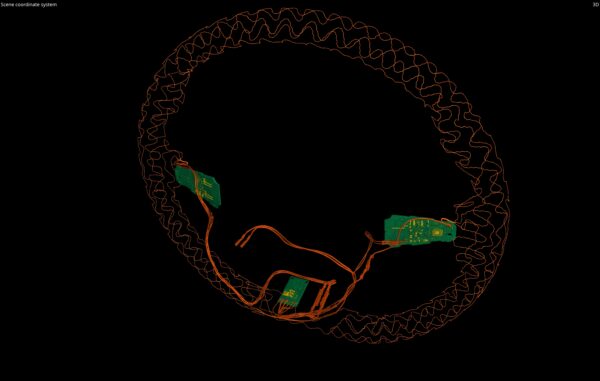

The second being the heating component of the wheel – where the activation signal goes from the button on the wheel, is regulated by a dedicated PCB in the lower arm of the wheel, to the embedded network of wires which provide the heating.

Figure 4: The electronics associated with the heating system of the steering wheel.

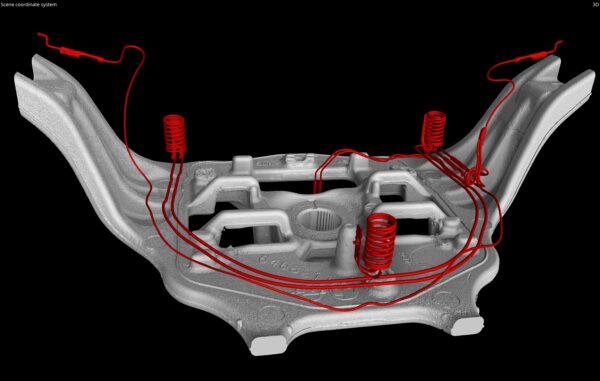

Lastly, we were able to identify the wiring associated with the horn in the wheel:

Figure 5: The electronics associated with the horn in the steering wheel.

Using the data, we were also able to inspect the active components of the horn- a set of sprung contacts which complete the circuit and activate the horn once the steering wheel is pressed.

Figure 6: the springs and contacts associated with the activation of the horn